Ingersoll showcases 3D printed winglet layup tool at IMTS

The part was printed with large 3D printing technology developed by Ingersoll Machine Tools and Oak Ridge National Laboratory.

Ingersoll Machine Tools Inc. (Rockford, IL, US) showcased at this week’s International Manufacturing Technology Show (IMTS, Chicago, IL, US) Master Print, the company’s new large-format 3D printing technology with automatic attachment change to 5-axis CNC for aerospace-grade milling. The technology was developed in collaboration with Oak Ridge National Laboratory (ORNL, Oak Ridge, TN, US).

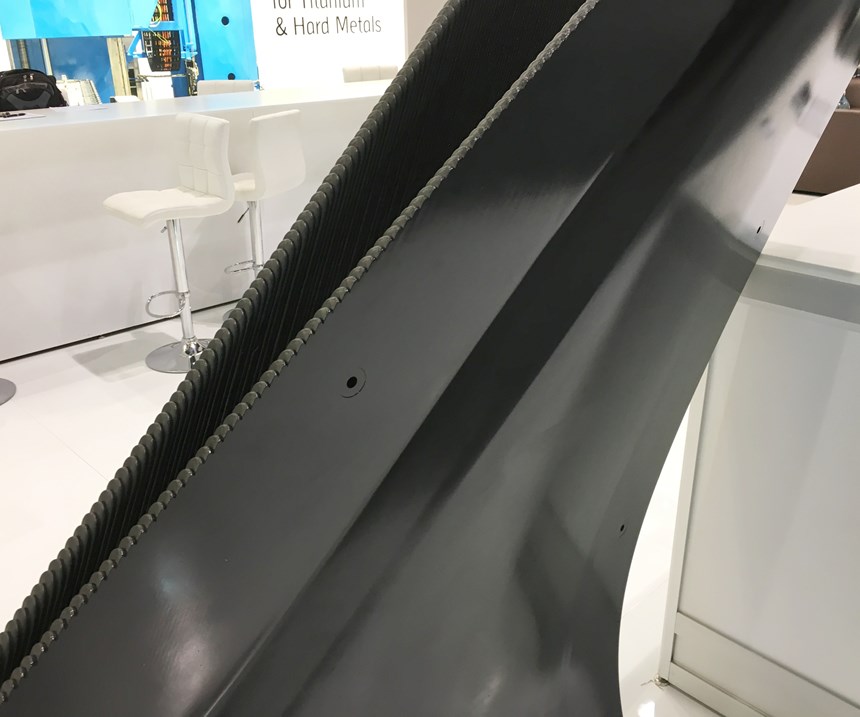

On display is the layup tool for a winglet shown in two stages. One is the just-printed tool. Second is the finished tool with sealant coating, ready to be used.

The part, says Ingersoll, weighs 430 lb/195kg and was printed in 6.5 hours. It was machined in 4.3 hours using the machine’s 5-axis technology. The material is ABS with 20% chopped carbon fiber reinforcement.

Related Content

-

Materials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

-

Composite rebar for future infrastructure

GFRP eliminates risk of corrosion and increases durability fourfold for reinforced concrete that meets future demands as traffic, urbanization and extreme weather increase.

-

Plant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

.png;width=70;height=70;mode=crop)