Grafen AB introduces graphene-coated textiles

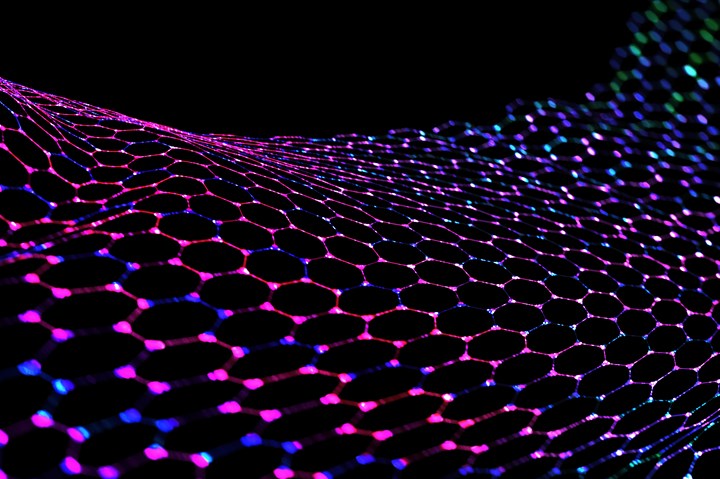

The G-Heatex series uses graphene flakes to entirely impregnate textiles for uniform electrical resistance properties. It is available for a range of textile substrate types.

Photo Credit: Getty Images

Grafren AB (Linköping, Sweden) has introduced G-Heatex, a series of graphene-coated textiles, which reportedly supply powerful and uniform heat while remaining soft, flexible, breathable and ultra-lightweight.

Grafren AB has recently patented two innovations, which are now covering its full production cycle. The company now has the technology for separating high-quality graphene flakes from any grade of incoming material. The access to the high-quality graphene will enable the company to work on graphene textiles.

“We invented the method to incorporate [the] smallest flakes of graphene inside of the fabric on the nanoscale level,” says Grafren’s Technical Director, Dr. Mike Zhyback. Graphene nanoparticles — or flakes — are entirely impregnated inside the fabric and coating layer by layer in every individual textile fiber. Because of the high electrical conductivity of graphene, attached flakes create a “conductive skin” on every fiber, which makes the entire fabric electrically active. Graphene can be coated on diverse textile substrates and the electrical resistance can be tailored depending on the application requirements.

Graphene textiles are said to have applications in defense, aerospace, healthcare, mobility and automotive due to the number of functions it possesses. Grafren says it is currently focused on the heating function of the fabric, as well as creating fully textile electrical heating elements to deliver uniform, homogeneous heat. The company claims that this is the only solution of its kind on the market.

Related Content

-

Composite rebar for future infrastructure

GFRP eliminates risk of corrosion and increases durability fourfold for reinforced concrete that meets future demands as traffic, urbanization and extreme weather increase.

-

Novel dry tape for liquid molded composites

MTorres seeks to enable next-gen aircraft and open new markets for composites with low-cost, high-permeability tapes and versatile, high-speed production lines.

-

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.