Fiber Patch Placement wins JEC Innovation Award in Seoul

Featuring a multi material feeding unit, Cevotec’s SAMBA Multi automates the time- and cost-intensive multi-material lay-up of aerospace sandwich components.

Cevotec (Taufkirchen bei München, Germany) together with Premium Aerotec (Augsburg, Germany) recently received the JEC Innovation Award for sustainability for a collaboration using Fiber Path Placement technology. The award was presented on Nov. 15 at JEC Asia (Seoul, South Korea).

Premium Aerotec teamed up with Cevotec to improve material utilization and reduce the overall cost of a pressure cap with a complex geometry. The project employed Cevotec’s SAMBA Series prepreg production system.

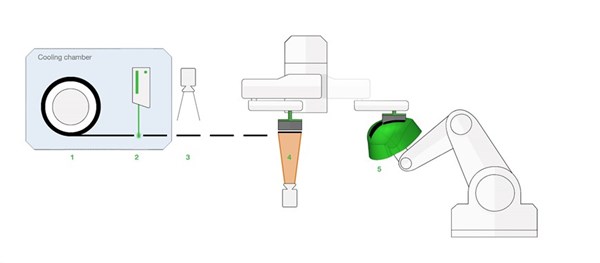

Featuring a multi material feeding unit, Cevotec’s SAMBA Multi automates the time- and cost-intensive multi-material lay-up of aerospace sandwich components. The continuous process monitoring, featured by all production cells of the SAMBA Series, enables a constant high placement accuracy and reportedly reduces time and cost required for individual unit tests particularly in aerospace industry.

SAMBA Pro thermoset prepreg configuration

Source | Cevotec

“With SAMBA Prepreg production cells, adjusted for processing ½ inch wide thermoset prepreg tape, we effectively ‘recycle’ the residual AFP tape [left over in typical AFP production processes],” says Felix Michl, CTO at Cevotec. “SAMBA also enables us to manufacture the specific part that Premium Aerotec had in mind: a pressure cap with a complex, double-curved shape and a circumferential flange for rivets so complex that regular fabrics could not be draped to achieve the desired geometry.”

According to Cevotec, designing and manufacturing the OP-box with FPP technology, using the residual AFP tape cut the part’s weight by 70%. The recurring costs reportedly could be decreased by 75% while the cost reduction thanks to the repurposing of the material could be around 88%.

Related Content

-

Novel dry tape for liquid molded composites

MTorres seeks to enable next-gen aircraft and open new markets for composites with low-cost, high-permeability tapes and versatile, high-speed production lines.

-

Thermoplastic composites welding advances for more sustainable airframes

Multiple demonstrators help various welding technologies approach TRL 6 in the quest for lighter weight, lower cost.

-

Price, performance, protection: EV battery enclosures, Part 1

Composite technologies are growing in use as suppliers continue efforts to meet more demanding requirements for EV battery enclosures.

.png;width=70;height=70;mode=crop)