FACC to supply engine fan cases for Pratt & Whitney

The fan cases, which FACC will manufacture in hybrid metal/composite construction, will be used on various business jets.

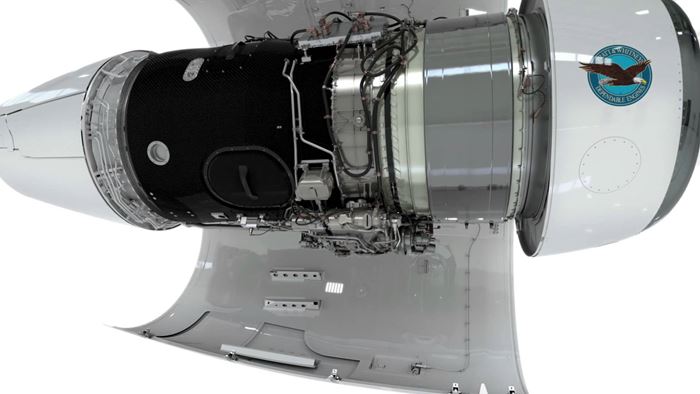

FACC has signed an agreement with Pratt & Whitney Canada, a Canadian engine manufacturer, to supply fan cases for the Pure Power engine family. The fan cases, which FACC will manufacture in hybrid metal/composite construction, will be used on various business jets. FACC is already supplying Pratt & Whitney Canada with a variety of components for a broad portfolio of engine families.

“The detail development of such components and the associated high component requirements were optimally solved by our engineering team. This enables us to offer our customers a weight- and performance-optimized high-tech product," said Günter Nelböck, vice president engines & nacelle of FACC. The FACC component represents a major contribution to flight safety, while the fan case is notable for its reduced weight as a result of its construction.

With the manufacture of fan cases, FACC has advanced into a new product and market segment. “We are constantly searching for new solutions to make aircraft engines even better, stronger, safer and lighter. This is a central prerequisite for being able to permanently sustain our position as a leading technology partner for airplane structures amid worldwide competition, and actively help shape future mobility,” says Robert Machtlinger, CEO of FACC.

Related Content

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

-

Carbon fiber in pressure vessels for hydrogen

The emerging H2 economy drives tank development for aircraft, ships and gas transport.

-

Materials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

.jpg;maxWidth=300;quality=90)