Exel Composites, Ziebel cooperate on oil well sensor

Exel subsidiary Diversified Structural Composites develops pultruded carbon fiber/epoxy rod with integrated sensor for downhole oil and gas drilling.

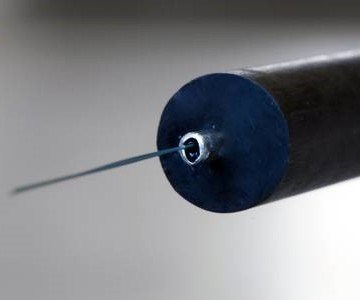

Exel Composites (Vantaa, Finland) company Diversified Structural Composites (DSC) reported on July 30 that it has developed a fiber-optic-embedded carbon fiber composite rod for Ziebel’s (Tananger, Norway) well intervention system. DSC’s expertise in carbon fiber pultrusion enabled the precision manufacture of the 15-mm-diameter rod with fiber optic core, which functions as a sensor, gathering valuable real-time insight on well behavior unattainable using conventional methods.

In order to make informed decisions, oil drilling and completions teams need detailed information on fluid flow in and around the borehole during production or injection. Such data is usually collected using production logging tools, but this method is operationally challenging and provides limited time- and location-specific information. Ziebel’s proprietary technology, the distributed fiber optic (DFO)-based Z-System, is said to be free of many of the constraints that limit conventional well logging effectiveness, offering improved understanding of well and reservoir behavior.

At the heart of Ziebel’s Z-System is the DSC-manufactured 6.2 -km-long, 15-mm-diameter carbon fiber rod (the Z-Rod), which delivers multiple fiber optic cables securely into the hostile downhole environment. Typically, the rod is deployed into a producing or injecting well for 48 hours where the fiber optic sensors measure temperature and acoustic vibrations along its length. This enables a variety of applications – including flow allocation, fluid movement visualization, leak detection and stimulation fluid monitoring – which are extremely valuable for optimal well and reservoir management.

This composites-based sensing system offers further advantages, says DSC. The carbon fiber rod enables horizontal well access, since the lightweight, stiff composite rod can be pushed from the surface into the horizontal sections frequently employed in today’s wells, which is not possible with conventional tools run on a wireline unless an electrical well tractor is employed. In addition, the small-diameter carbon fiber rod can access wells with restricted internal diameters and difficult geometry where other tools will not pass. It also minimizes the choking effect on the well, and unlike metals, it is inert to the majority of hazardous and corrosive substances found in the downhole environment.

Ziebel contacted US-based carbon fiber pultrusion specialist DSC in 2006 to develop and manufacture the composite rod required to launch its fiber optic intervention technology in the oil sector.

To ensure the required combination of strength, stiffness and corrosion resistance necessary for this application, DSC selected one of its proprietary, tough epoxy resins and a specific carbon fiber selected through extensive testing to maximize mechanical performance. This resin places particularly challenging demands on the pultrusion process, since it requires a very slow cure in order to attain its optimal properties. This means that to produce each 6.2-km-long rod, the pultrusion line must run continuously, without fault, for more than three weeks.

"Because of the high cost of both the carbon fiber and the fiber optics, the process risk is very high," David Lewis, DSC's director of technology and business development explains. "We've therefore performed extensive work to develop a pultrusion process that is extremely robust and foolproof, and exceptional process controls are in place to ensure that there are no failures."

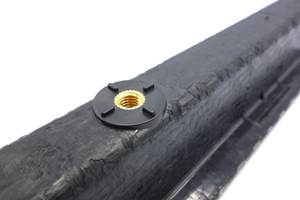

Ziebel and DSC have worked together to optimize a spooling technology to facilitate the handling and transport of long lengths of pultruded rod. This enables the stiff carbon fiber rod to be wound onto reels that are small enough in diameter to allow shipping from DSC’s production facilities in Erlanger, KY, US, to Europe and the Middle East, as well as within the US. An NDT process is used to monitor rod quality, since the product is continuous it cannot be cut for inspection.

"We have a great deal of trust and confidence in our partners at DSC that will enable us to continue pushing the boundaries for carbon composites in the hostile downhole environments of oil and gas wells. Our next generation of Z-Rod will take us to operating temperatures of 350°F (177°C), opening up additional wells for our services," says Neil Gardner, Ziebel's vice president of technology.

Related Content

Composite profiles bring consistent quality to Ant-X drones

Italian drone solutions provider enlists Exel Composites to deliver pultruded and pull-wound profiles that support prototype drone structure designs.

Read MoreRobotized system makes overmolding mobile, flexible

Anybrid’s ROBIN demonstrates inline/offline functionalization of profiles, 3D-printed panels and bio-based materials for more efficient, sustainable composite parts.

Read MoreSeat frame demonstrates next-generation autocomposites design

Light weight, simplified/cost-effective manufacturing, passenger comfort and safety informed materials and process innovations and won awards for the 2022 Toyota Tundra‘s second-row seat frame.

Read MoreBiocomposite for mobile architecture, low load-bearing applications

The German Institutes of Textile and Fiber Research and partners have developed a biocomposite well suited for support profiles and connecting nodes in construction applications.

Read MoreRead Next

Composites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read More