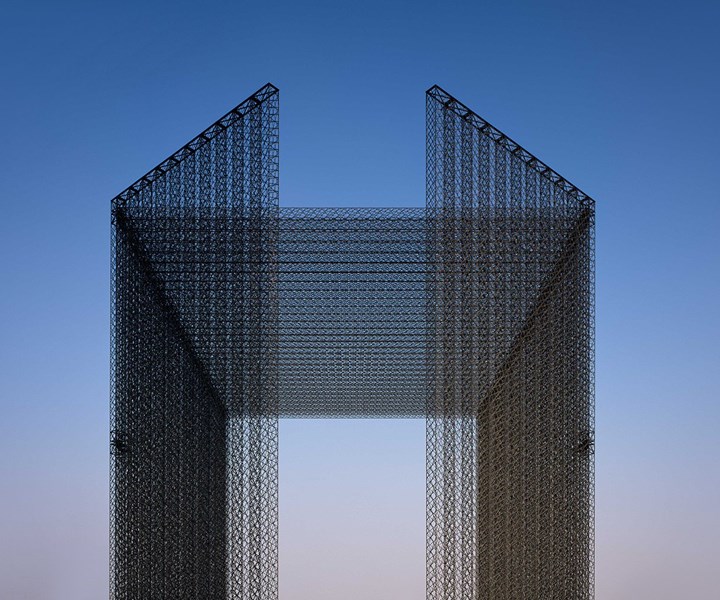

Dubai Expo 2020 unveils carbon fiber entry portals

Dubai Expo 2020 entryway portals were made from carbon fiber using a 3D weaving process.

Source | Expo 2020

British architecture firm Asif Khan (London, U.K.) has unveiled three carbon fiber entry portals created for the Dubai Expo 2020. The 21-meter high lattice gateways are positioned on bridges spanning roads leading to the expo site. They are woven from carbon fiber ribbon using a 3D weaving process where the carbon fiber is wrapped around a rotating arm.

The entry portal design is based on mashrabiya, a traditional Islamic architectural latticework used to shade windows and balconies. The lattices cast intricate patterns of shadows, creating a dappled lighting effect.

Each mashrabiya portal is 30 meters long and 21 meters high and is made up of carbon fiber lattice columns that are bolted onto the bridges. Each has 10.5-meter high doors that welcome visitors, representing, as stated on the Expo 2020 website, “a symbolic act of Expo 2020’s doors being literally thrown open to the world.”

Related Content

-

Braskem demonstrates PP solutions using Weav3D composite lattice technology

Partnership combines Braskem’s polypropylene sheets with Weav3D Rebar for Plastics technology to address new structural, automotive applications requiring high-strength, lightweight material solutions.

-

Biteam introduces 3D Noodle International AB spin-off for 3D fabric noodles

Biteam 3D’s third spin-off implements its proprietary 3D weaving technology to produce a variety of carbon, ceramic and other fiber 3D fabric noodle preforms.

-

3D weaving capabilities achieve complex shapes, reduce weight and cost

JEC World 2024: Bally Ribbon Mills is displaying film-infused 3D woven joints, woven thermal protection systems (TPS) and woven composite 3D structures.

.png;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)