CompositesWorld News for Jan. 03, 2020

Read news from Ahlstrom-Munksjö Glassfibre Oy, and Lockheed Martin Aeronautics

Top 10 CW news from the 2010s

From 2010-2019, here are CompositesWorld’s most viewed composites industry news from the decade.

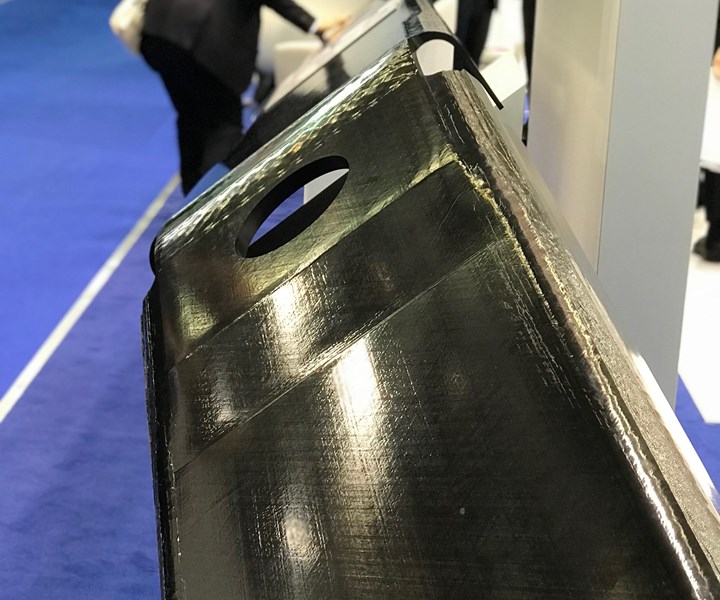

TenCate thermoplastic composite spar, JEC World 2018. TenCate Advanced Composites was acquired by Toray in 2018.

What composites industry news will shape the 2020s? As CW gears up for the new year and new decade, we have also collected our Top 10 most-viewed news stories from 2010-2019:

- Carbon fiber engine block revealed (2011). Composite Castings LLC (Palm Beach, Fla.) announced the development of a new, lightweight carbon fiber composite four-cylinder engine block, which used fiber from Toho Tenax America and weighed 45-50% less than a comparable aluminum block.

- Hexion/Momentive merger made official (2010). Momentive Performance Materials announced that it had completed its acquisition of epoxy manufacturer Hexion Specialty Chemicals, creating a new company that kept the Momentive name.

- Spirit AeroSystems debuts next-generation fuselage panel (2019). The top news post from 2019 introduced Spirit AeroSystems (Wichita, Kan. U.S.) 18-by-12-foot (5.5-by-3.7-meter) demonstrator panel, which features integrated skin and stringers and offers substantial cost savings combined with strong performance attributes.

- SABIC and Kringlan developing first carbon thermoplastic composite wheel (2014). SABIC, Kringlan and other industry partners announced that their collaborative technology was close to commercialization in automotive while targeting other industries, including energy-efficient appliances. (Note: for CW’s most recent coverage of carbon fiber composite wheels, see our January 2020 cover story.)

- Swede preps for around-the-world journey in 10-ft sailboat (2014). Sven Yrvind, 75, announced his plans to sail around the world in his 10-foot, 1.5-ton sailboat, which he made using DIAB Divinycell composites.

- BMW formally launches i3 manufacture and assembly (2013). As BMW formally launched manufacture of the composites-intensive i3, the company reveals more information about the composites manufacturing and assembly process at its German facilities.

-

Revolutionary fuselage concept unveiled by MTorres (2017). MTorres (Torres de Elorz, Navarra, Spain) introduced its paradigm-changing monocoque composite fuselage, made without fasteners or molds and with carbon fiber that could cut raw material cost by 50%.

-

Sixty-second cycle time for carbon composites? (2011). Teijin (Tokyo, Japan) announced its breakthrough process using press-forming and thermoplastics to produce carbon fiber composite parts in less than 60 seconds. (Note: See CW’s most recent coverage on Teijin’s Sereebo process.)

-

Citroën DS3 supercar sports carbon/aramid composite body panels (2013). The 600-horsepower speedster driven by former World Rally Champion Peter Solberg in the 2013 European Rallycross Championships featured 11 vacuum-infused composite body panels made with Crestapol 1250LV urethane acrylic resin from Scott Bader Co. Ltd. (Northamptonshire, U.K).

- Toray acquires TenCate Advanced Composites (2018). Toray, the world’s largest carbon fiber manufacturer, acquired TenCate Advanced Composites to shore up its thermoplastic composites capabilities.

To stay on top of composites news in 2020, subscribe to our email newsletter CW Today.

Ahlstrom-Munksjö completes the sale of glass fiber reinforcement business

On Dec. 31, Ahlstrom-Munksjö announced that it has completed the sale of its glass fiber reinforcement business in Mikkeli, Finland, to Vitrulan Composites Oy.

On Dec. 31, Ahlstrom-Munksjö (Mikkeli, Finland) announced that it has completed the sale of its glass fiber reinforcement business in Mikkeli, Finland, to Vitrulan Composites Oy, a fully owned subsidiary of Vitrulan Group and part of the family-owned industrial holding ADCURAM Group.

The transaction was announced on November 21, 2019. Ahlstrom-Munksjö reported then that it will continue its glass fiber production operations at its plants in Karhula, Finland and Tver, Russia.

Ahlstrom-Munksjö’s Mikkeli plant produces glass- and carbon fiber-based reinforcement fabrics, particularly glass fiber reinforcements for wind energy, marine and transportation applications. At the end of 2018, the plant employed about 100 people and net sales of approximately €30 million ($33 million).

Vitrulan Group produces highly resilient glass fiber-based woven materials, has approximately 400 employees and generates net sales of approximately €60 million ($66 million). Its woven materials are used in public and private buildings, reinforcing and backing fabrics, laminates and special products.

ADCURAM comprises six subsidiaries with a combined sales of more than €400 million and around 2,500 employees globally. It actively develops its subsidiaries with the aim of significant growth.

Lockheed Martin delivers 134 F-35 aircraft in 2019

Lockheed Martin reports that it exceeded its 2019 delivery goals for the F-35 defense aircraft, and plans to deliver 141 F-35s in 2020.

F-35. Source | Lockheed Martin

Lockheed Martin (Ft. Worth, Texas, U.S.) announced on Dec. 30 that it had delivered its 134th F-35 aircraft for 2019, exceeding the joint government and industry 2019 delivery goal of 131 aircraft.

The company says that 134 deliveries represents a 47% increase from 2018 and nearly a 200% production increase from 2016. In 2020, Lockheed Martin plans to deliver 141 F-35s and says it is prepared to increase production volume year-over-year to hit peak production in 2023.

The 134th aircraft is a short takeoff and vertical landing (STOVL) model for the United States Marine Corps. In 2019, Lockheed Martin reports that deliveries included 81 F-35s for the United States, 30 for international partner nations and 23 for foreign military sales customers.

“This achievement is a testament to the readiness of the full F-35 enterprise to ramp to full-rate production and we continue to focus on improving on-time deliveries across the entire weapons system,” says Greg Ulmer, Lockheed Martin vice president and general manager of the F-35 program. “We have met our annual delivery targets three years in a row and continue to increase production rates, improve efficiencies and reduce costs. The F-35 is the most capable fighter jet in the world, and we're now delivering the 5th Generation weapon system at a cost equal to or lower than a less capable 4th Generation legacy aircraft.”

According to Lockheed Martin, the current price of an F-35A is $77.9 million, meeting the $80 million goal a year earlier than planned. The global F-35 fleet, which includes more than 490 aircraft operating from 21 bases around the globe, is reported to average greater than 65% mission capable rates, with operational squadrons consistently performing near 75%. Lockheed Martin's sustainment cost per aircraft per year has decreased for four consecutive years, and more than 35% since 2015. As of Dec. 30, 2019, 975 pilots and 8,585 maintainers are trained, and the F-35 fleet has surpassed more than 240,000 cumulative flight hours.

Elon Musk teases Vegas Hyperloop tunnel for 2020

The Boring Co. hopes to complete a Hyperloop project in Las Vegas in 2020 that would carry passengers between the Las Vegas Convention Center (LVCC) and the Las Vegas Strip.

Source | The Boring Co.

Boring Co. (Hawthorne, Calif., U.S.) founder Elon Musk tweeted on December 27 that the company hopes to complete a Hyperloop project in Las Vegas that would carry passengers between the Las Vegas Convention Center (LVCC) and the Las Vegas Strip. The digging of the tunnel reportedly began in November 2019. The project will consist of an approximately 1-mile long twin tunnel loop system and transport passengers via autonomous electric vehicles (AEVs) — presumably modified Tesla vehicles — at speeds around 155 miles per hour.

Hyperloop is a longtime pet project for Musk who also serves as the CEO for SpaceX (Hawthorne, Calif., U.S.) and Tesla (Palo Alto, Calif., U.S.). Musk originally published his Hyperloop Alpha white paper in 2013, and since then the concept has captured the imagination of the public as a possible fifth mode of transportation that would use pods to transport passengers and freight at high speeds through a tube or series of tubes designed to reduce air resistance using a partial vacuum.

SpaceX has continued to support Hyperloop through its Hyperloop Pod competition, which has been held annually at the company’s Hyperloop test track in Hawthorne, Calif., U.S., since its inception in 2015. Following the July 2019 competition, SpaceX announced plans to build a new 10 kilometer-long (roughly 6 miles) Hyperloop track to be used for the 2020 pod competition.

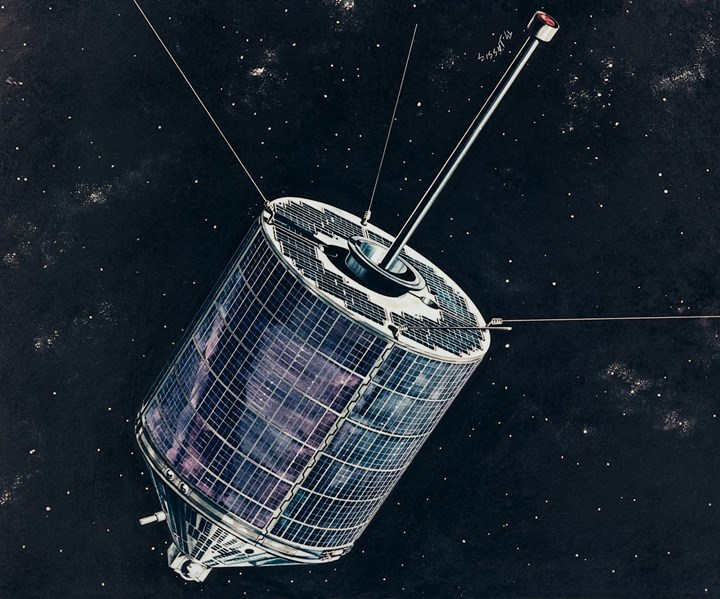

Researchers develop nano-barrier for CFRP space applications

Developed by the University of Surrey and Airbus, the new nano-barrier material is intended to eliminate moisture absorption issues in spacecraft components.

Source | Airbus

Researchers from the University of Surrey (Surrey, U.K.) and Airbus Defence and Space (Ottobrunn, Germany) have developed a multi-layered nano-barrier that bonds with carbon fiber-reinforced polymers (CFRP), designed to eliminate the need for multiple bake-out stages in an effort to solve moisture absorption issues in space applications.

In their work published in the journal Nature Materials, the researchers have shown that their nano-barrier — which measures only sub-micrometers in thickness, compared to the tens of micrometers of current space mission coatings, the researchers say — is less susceptible to stress and contamination at the surface, keeping its integrity even after multiple thermal cycles.

“We are confident that the reinforced composite we have reported is a significant improvement over similar methods and materials already on the market,” says Professor Ravi Silva, director of the Advanced Technology Institute at the University of Surrey. “These encouraging results suggest that our barrier could eliminate the considerable costs and dangers associated with using carbon fiber-reinforced polymers in space missions.”

“We have been using carbon fiber composites on our spacecraft and instrument structures for many years, but the newly developed nano-barrier together with our ultra-high-modulus CFRP manufacturing capability will enable us to create the next generation of non-outgassing CFRP materials with much more dimensional stability for optics and payload support. Reaching this milestone gives us the confidence to look at instrument-scale manufacturing to fully prove the technology,” says Christian Wilhelmi, head of mechanical subsystems and research and technology Friedrichshafen at Airbus Defence and Space.

Related Content

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreHighly tunable, woven lattice reinforcements target automotive structures

CAMX 2023: Startup Weav3D will be demonstrating its two collaborative automotive demonstrator parts and present two conference papers.

Read More3D weaving capabilities achieve complex shapes, reduce weight and cost

JEC World 2024: Bally Ribbon Mills is displaying film-infused 3D woven joints, woven thermal protection systems (TPS) and woven composite 3D structures.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreRead Next

Composites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read More

.jpg;maxWidth=300;quality=90)