CompositesWorld News for Feb. 05, 2020

Read news from Conbility, David H Sutherland & Co., Teijin, Institute of Plastics Processing (IKV) at RWTH Aachen University, and AZL Aachen | Excellence in Lightweight Production

Employment Opportunity: Senior Applications Engineer, Materia

Materia is seeking a Senior Applications Engineer for advanced composites applications.

Materia (Pasadena, Calif., U.S.) is seeking a Senior Applications Engineer to lead the engineering, processing project support and technical project management required for new customers to adopt Materia Proxima resins in advanced composite applications.

Essential Duties and Responsibilities:

- Serve as the engineering expert that supports new customers and development projects for advanced composite applications in major industries using pultrusion, filament winding, and HP-RTM/C-RTM processes.

- Develop process and manufacturing recommendations that enable customer adoption of Materia products.

- Collaborate closely with customer engineering teams to facilitate successful technology transfer and process scaleup.

- Coordinate and execute product trials and demonstrations at customer facilities.

- Work closely with colleagues to make test samples and provide technical feedback needed for developing new or improved resin processes and/or formulations.

- Maintain careful records, produce reports and other documents to meet technology dissemination, patent protection, and/or quality control needs.

- Work with colleagues to manage and maintain facility organization and safety.

Qualifications and Experience:

Education

- B.S. in engineering, material science or similar. Consideration will also be given to qualified individuals with a Certified Composites Technician Degree (CCT).

Experience

- 7+ years of relevant technical experience.

- Thorough understanding and experience with pultrusion processes and equipment for liquid thermoset resins is preferred; experience with HP-RTM, C-RTM and filament winding is a plus.

- Prior experience with direct customer interactions in a technical role

- Demonstrated technical problem-solving ability.

- Significant hands on experience and technical background related to working in laboratories and/or manufacturing environments.

- Strong oral and written communication skills.

- Good project and time management skills.

- Travel requirement: 25-50% expected (domestic and international).

- Location: Pasadena, Calif., U.S.

To submit an application, visit https://materiainc.applicantpro.com.

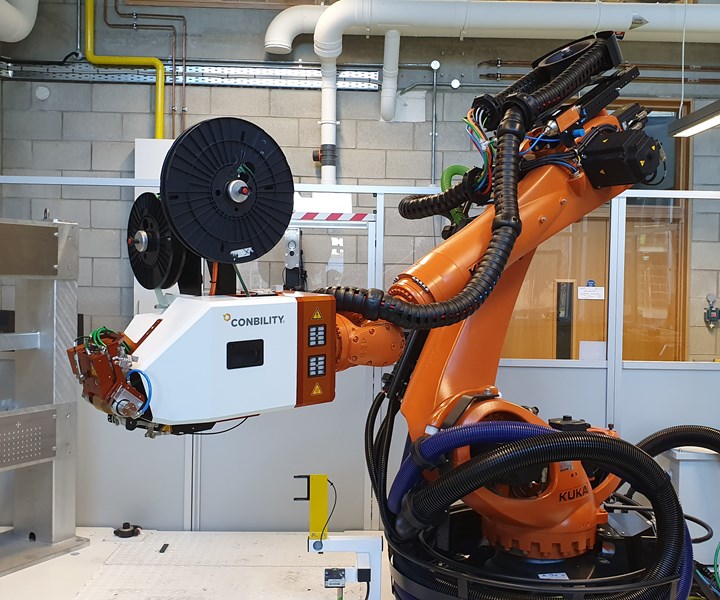

Conbility tape placement head installed at University of Limerick

The PrePro 3D system combines laser-assisted thermoplastic tape placement with IR-assisted thermoset prepreg placement.

The multifunctional PrePro3D head installed at the existing robot system at the University of Limerick. Source | Conbility GmbH

Conbility GmbH (Aachen, Germany) announced that it has recently delivered a modular 3D Tape Placement Applicator for tape winding and tape placement to the Bernal Institute of the University of Limerick, Ireland.

According to Conbility, the PrePro 3D system combines three technologies in one modular system: laser-assisted thermoplastic tape placement, infrared (IR) assisted thermoset prepreg placement, and the unwinding of backing paper and dry fiber placement. The system installed in Limerick is equipped with an infrared heating source but Conbility says it can be easily upgraded with a high-power diode laser system.

The JEC-award-winning PrePro 3D tape placement and winding applicator is available as modular tool with decentral control system and HMI (including closed-loop control of energy input into the processing zone) for the “plug-in” implementation in existing robot systems or machine systems by standard interfaces for the communication with the master control system. Conbility provides the single applicator as well as turn-key ready systems including the robot and handling systems as well as the laser-safe manufacturing cell.

The PrePro 3D head is based on 25 years of development work at the Fraunhofer Institute for Production Technology (IPT) regarding laser-assisted tape processing with in-situ consolidation. Since 2018, Conbility GmbH has been a contract partner of the Fraunhofer Institute for Production Technology, IPT for the commercialization and further development of the PrePro 2D and PrePro 3D tape placement systems.

“… [This system] will significantly enhance our capability to conduct research on processing of novel composite structures, allowing us to realize and validate the novel designs developed by our research team for a variety of high-performance applications. We already have a number of projects underway which will use this equipment, in conjunction with the SFI Confirm Smart Manufacturing Research Centre and look forward to the future research opportunities it will enable,” says Dr. Ronan O’Higgins, Bernal Institute, University of Limerick.

Funding for this equipment was provided by Science Foundation Ireland (SFI) for funding Spatially and Temporally VARIable COMPosite Structures (VARICOMP).

DHSutherland partners with KleanVak for promotion of surface preparation technology

DHSutherland will promote France-based KleanVak’s mold preparation and solvent cleaning technology to customers in the Americas.

Source | DHSutherland and KleanVak

DHSutherland (Beaverton, Ore., U.S.) has entered into a partnership with KleanVak (Biarritz, France) to promote KleanVak’s patented surface application tool technology across the Americas. The DHSutherland technical team also will be trained by KleanVak to ensure its certified support of DHSutherland from initial set-up to ongoing preventative maintenance.

KleanVak has developed equipment that represents the next generation of technology for applying chemicals to surfaces for mold preparation and solvent cleaning. KleanVak’s patented technology sprays a thin layer of solvent onto the surface of the tool or part to be cleaned, while simultaneously vacuuming and safely containing any volatile organic compounds (VOC) that would otherwise flash into the surrounding environment. The action of applying the solvent while removing VOCs also reduces by 80% the wait time required between coats. This is said to increase mold utilization, meaning more time can be spent making/cleaning parts.

“Partnering with KleanVak is a very exciting opportunity that the DHSutherland team is thrilled to promote to our customer partners. KleanVak’s proprietary technology will deliver substantial value to by significantly improving worker safety while reducing mold prep times, enabling out customer-partners to spend more time on value-added work,” says Andrew Crouse, DHSutherland president.

“DHSutherland’s culture and commitment, providing an exceptional experience to the advanced composites customers, makes for a partnership that will help establish the KleanVak brand in the Americas as industry best practice for mold prep and surface-cleaning applications,” says Vincent Garcia, KleanVak CEO.

Teijin, Envision Virgin Racing announce multi-year partnership

The Teijin Group will develop high-performance materials and products for the team’s all-electric Formula E racecars.

Source | Teijin

Global fibers technology company Teijin Group (Tokyo, Japan) and Envision Virgin Racing announced on Jan. 29 that they have agreed to a multi-year sponsorship contract that will support the team’s participation in the ABB FIA Formula E Championship.

Envision Virgin Racing has been competing in the all-electric Formula E race series since its start in 2014, experiencing success in the sport while also seeking sustainable mobility solutions and promoting environmental issues with its “Race Against Climate Change” initiative.

Through this new partnership, the Teijin Group will develop high-performance materials and products to improve the comfort of Envision Virgin Racing drivers, and explore new business opportunities through the development and provision of lightweight, high-performance automotive components. The companies have also established a sponsorship agreement, which Teijin will use to raise awareness for the Teijin brand in related industries.

“By supporting Envision Virgin Racing, which competes in races with electric vehicles (EV) as a means of raising awareness of global warming, we will develop technologies and accumulate the know-how and solution capabilities required for future EVs that satisfy ever-stricter environmental regulations,” says Jun Suzuki, president and CEO of Teijin Ltd.

“… Being able to tap into [Teijin’s] wealth of expertise and high-performance material and composite technologies will help us on track, while away from the track we’re looking forward to working together on our ‘Race Against Climate Change’ program,” says Sylvain Filippi, the team’s managing director.

Launched in 2014, Formula E is the world’s first fully-electric single-seater racing series, competing on city center circuits globally. The championship represents a vision for the future of the motor industry, serving as a platform to showcase the latest innovations in electric vehicle technology and alternative energy solutions.

The next Formula E race takes place in Mexico City on Feb. 15, where The Teijin Group will officially commence its full support for the U.K.-based team.

AZL, IKV launch SMC data bank and testing project

Researchers and partner companies aim to standardize the provision of engineering data for long fiber-reinforced sheet molding compounds (SMC).

Michael Kiesel from Siemens talks about focus points for SMC technology for interior components in Siemens Mobility at a previous High-Performance SMC Workgroup meeting. Source | AZL Aachen GmbH

A collaboration of researchers have launched a project for the standardized provision of engineering data for sheet molding compounds (SMC). The AZL Workgroup “High-Performance SMC” was developed by AZL Aachen GmbH in cooperation with Aachen Center for Integrative Lightweight Production (AZL) and Institute of Plastics Processing (IKV) of RWTH Aachen University (Aachen, Germany). Within the scope of the project, companies along the value chain are invited to participate in the definition of the required characteristic material data, the guidelines for the production of test specimens and the test specifications.

According to AZL, requirements to reduce the production costs of lightweight components are driving work toward a new generation of SMCs with higher mechanical properties. SMC, the researchers say, offers potential to realize structural components with good lightweight characteristics at significantly reduced costs compared to conventional continuous fiber-reinforced components.

To achieve this, the AZL Workgrouup is developing a data bank to harmonize material data on SMCs, and to provide the possibility of easily finding the right material for specific requirements.

Currently, a data bank for engineered thermoplastic materials, called CAMPUS, already exists, and will serve as a basis for the AZL Workgroup data bank.

Participants of the last High-Performance SMC Workgroup meeting, in which AZL and IKV presented the project proposal. Source | AZL Aachen GmbH

“The segment of SMC is, with 250,000 tons production per year, the largest composites market in Europe. ... The goal is to have a similar data base as already established by Campus for thermoplastics and thermoplastic composites. Only with a reliable set data we can convince the engineering experts to use SMC in a larger variety of applications,” says Dr. Michael Effing, chairman of the board of AVK and Composites Germany.

AZL, IKV and other companies along the value chain of long fiber-reinforced SMC, under the lead of Dr. Edwin Baur, CEO of M-Base Engineering + Software GmbH (Aachen), intend to build a CAMPUS-compatible data structure and material characterization methodology during upcoming High-Performance SMC Workgroup meetings.

The companies also plan to develop a testing program to characterize the SMC materials within a Joint Partner Project with partners from industry. The project which will include testings on one of AOC Aliancys’ (Collierville, Tenn., U.S.) newly designed SMC test tools.

The project will define the appropriate material properties of commercially available SMC materials that can be used by stakeholders involved in the material selection. Furthermore, appropriate material parameters that enable a detailed material selection within the framework of the preliminary design will be investigated. The process-dependent material parameters for the design of process and structure will also be discussed in the course of the project.

Additionally, the project will address how the characteristic values can be used for process and structure simulation and which tests and production parameters provide significant, appropriate process-dependent material parameters at manageable costs.

During the project, test specimens will be produced from three first representative materials selected by the consortium, and the suitability of the proposed test procedure for the different materials will be assessed. The project will include the testing of the processes and mechanical properties as well as the feasibility of the proposed test methods for the different materials.

The project will begin May 19, 2020 and is expected to have a duration of 6 months. Companies who wish to participate can contact Philip Fröhlig, senior project manager at AZL Aachen GmbH at philipp.froehlig@azl-aachen-gmbh.de.

Hengrui Corp. (Lianyungang City, China), Polynt (Carpentersville, Ill., U.S.), Siemens (Waltham, Mass., U.S.) and AOC Aliancys are among the companies who participated in the initiation of this project.

Related Content

Composite resins price change report

CW’s running summary of resin price change announcements from major material suppliers that serve the composites manufacturing industry.

Read MoreMaterials & Processes: Resin matrices for composites

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.

Read MoreMaterials & Processes: Fibers for composites

The structural properties of composite materials are derived primarily from the fiber reinforcement. Fiber types, their manufacture, their uses and the end-market applications in which they find most use are described.

Read MoreFrom the CW Archives: Airbus A400M cargo door

The inaugural CW From the Archives revisits Sara Black’s 2007 story on out-of-autoclave infusion used to fabricate the massive composite upper cargo door for the Airbus A400M military airlifter.

Read MoreRead Next

Composites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read More

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)