CompositesWorld News for Feb. 03, 2020

Read news from Cevotec, SPE Automotive Division, KRÜSS USA, ACMA - American Composites Manufacturers Association, and AIMPLAS

JEC announces finalists for 2020 Innovation Awards

JEC Group has announced its JEC Innovation Awards finalists, 33 total from 11 categories. Winners will be announced at JEC World 2020 on March 4.

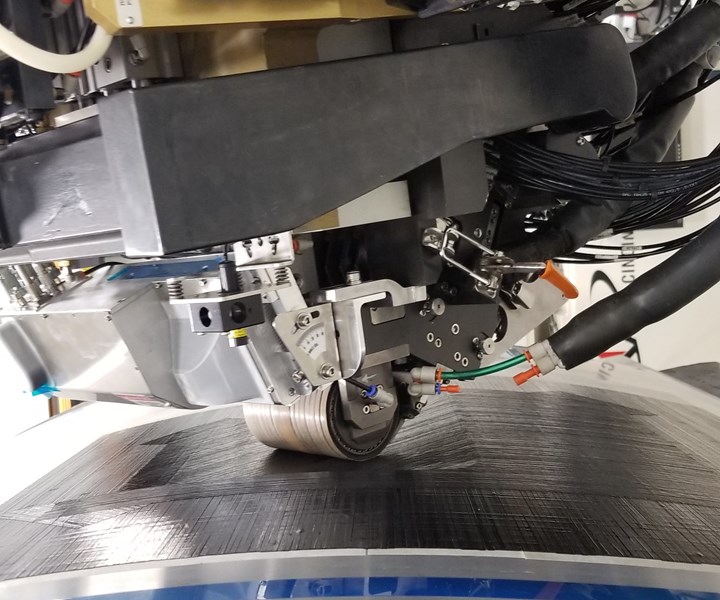

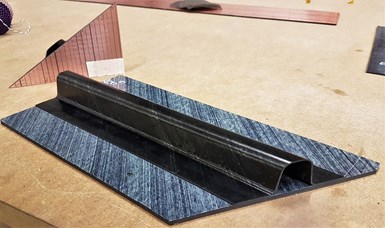

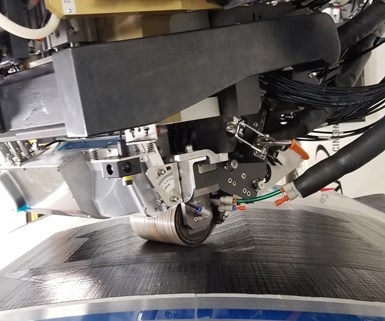

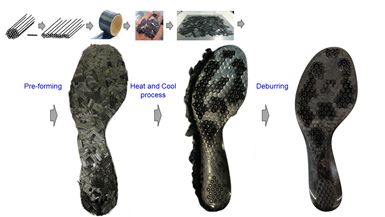

Fives/NRC in-process inspection platform. Source, all images | JEC Group

JEC Group (Paris, France) has announced the finalists for its annual JEC Innovation Awards. After pre-selecting 33 finalists, the jury now has one month to select a winner in each of 11 categories. The winners will be honored at an awards ceremony to take place during JEC World 2020 on Wednesday, March 4, at 5 p.m., on the Agora stage (Hall 5).

The international jury represents the entire composites value chain:

- Anurag Bansal, Manager Global Business development, ACCIONA Construction S.A.

- Christophe Binetruy, General Chairman & Professor, EC Nantes

- Robert Buchinger, Business Development Advanced Industry Systems, Swarco

- Chantal Fualdes, Head of Airframe Certification, Executive Expert Composite Airframes, Airbus

- Karl-Heinz Fuller, Manager hybrid materials, concepts and AMG, Daimler

- Sung Ha, Professor, Department of Mechanical Engineering, Hanyang University

- Deniz Korkmaz, Ph.D. Composite Technologies Director, EMEA, Kordsa

- Brian Krull, Global Director of Innovation, Magna Exteriors

- Yann Penfornis, Managing Director, Multiplast

- Henry Shin, Director - R&D Composites Innovation Centre, KCTech

- Kiyoshi Uzawa, Professor/ Director (Ph.D.), Innovative Composite Centre

An online voting process will be held for each category to choose a second-place winner for the general public’s favorite innovations. Beginning Feb. 1, the public will be able to vote online at http://innovationawards.jec-world.events.

Finalists for each category are listed below:

Hengshen to develop components for C919 aircraft composite tail

Hengshen Co. and the Commercial Aircraft Corp. of China (COMAC) will collaborate on development of specialized components for the C919 tail optimization project.

The C919 aircraft during its maiden flight in 2017. Source | COMAC

Jiangsu Hengshen Co. Ltd. (Hengshen; Danyang City, China) and the Commercial Aircraft Corp. of China Ltd. (COMAC; Shanghai) recently signed a memorandum of understanding (MOU) for the development of specialized components for the C919 aircraft composite tail optimization project.

The C919 aircraft is a large civil jet aircraft independently developed by China in accordance with international civil aviation regulations. The C919 aircraft has a layout of 158-168 seats, and a range of 4,075-5,555 kilometers. According to Hengshen, project demonstration, feasibility study and pre-development have been completed and the program is entering into the engineering development phase. The first aircraft rolled out on Nov. 2, 2015, with first flight tests on May 5, 2017. A total of 815 orders have been obtained from 28 customers.

Most recently, COMAC has initiated design, development, production and selection of specialized suppliers for a project to optimize the C919 aircraft’s composite tail.

The signing of this MOU is COMAC’s recognition of Hengshen as a company capable of developing and manufacturing aircraft composite components, and marks the official participation of Hengshen in the project. The two companies commit to share resources and information through technical exchanges and project cooperation to jointly promote the project and to achieve project objectives.

Qian Simon, chairman of Hengshen, expressed that the Hengshen company will cooperate extensively with COMAC and will support the necessary technical requirements of the project by supplying professional experienced personnel to improve the design and manufacturing of specialized components for the C919 aircraft. Additionally, the company will assist in the development of the airworthiness quality system.

Cevotec, Fuji sign exclusive sales partnership for Japan and Thai markets

Japan-based Fuji Industries has exclusive rights to sell Cevotec products in the region, including Fiber Patch Placement composites automation technology.

Company representatives including Junji Yamada, president of Fuji Industries Co. Ltd. (pictured left), and Felix Michl, chief technical officer of Cevotec (pictured right), met at Cevotec headquarters to sign the partnership agreement. Source | Cevotec

Automation specialist Cevotec GmbH (Munich, Germany), known for its Fiber Patch Placement (FPP) technology, and Fuji Industries Co. Ltd. (Kobe, Japan) have signed an exclusive representation and reseller agreement, giving Fuji the license to exclusively represent Cevotec in Japan and Thailand and to offer the entire range of Cevotec products to interested customers.

“With some of the world’s largest fiber manufacturers based in Japan, this is a very important market for composites,” says Thorsten Groene, managing director of Cevotec. “Already in 2017, at the launch of SAMBA production system at JEC World, strong interest from Japanese manufacturers in Fiber Patch Placement technology became apparent. After deepening existing contacts and establishing new ones during a delegation trip to Japan in 2018 by our CTO Felix Michl, we decided to serve the Japanese market structurally with Fuji Industries an established partner with excellent network in aerospace and other composite-intensive industries.”

“FPP technology has the potential to revolutionize composites industry,” says Makoto Nitta, senior managing director at Fuji, responsible for composites products. According to Nitta, the technology has had Fuji’s attention since its 2017 launch, and now, Fuji is exclusively licensed to represent Cevotec and offer all Cevotec products in Japan and Thailand. The partners will also collaborate closely in customer service to provide turnkey solutions including after-sales services and support.

“We believe that Fuji Industries' longstanding customer relationships, especially in the aviation industry, will open up new business opportunities for us,” says Felix Michl, chief technical officer of Cevotec.

Fuji Industries draws on decades-long experience in the composites market. With more than 70 years of successful history, the company is a trusted supplier for high-tech products for the Japanese industry, in particular aerospace.

Cevotec reports that its Fiber Patch Placement technology offers unparalleled flexibility and efficiency for the automated layup of high-performance composite parts. The SAMBA Series production cells enable the fully automated, multi-material lay-up of geometrically complex components and sandwich structures, processing up to four different materials. Self-corrective process control systems guarantee a highest-quality layup, fully documented. According to Cevotec, these benefits usually translate into baseline savings of 20-60% in production cost and time when switching from manual lay-up to Fiber Patch Placement.

Composites events to cover recycling, sustainability, gel coats and more

Recently announced composites events news includes new events and speaker abstract deadlines from the ACMA, AIMPLAS, KRÜSS, Polynt-Reichhold and SPE.

Source | AIMPLAS

Recently announced composites events news includes new events and speaker abstract deadlines from the ACMA, AIMPLAS, KRÜSS, Polynt-Reichhold and SPE.

ACMA opens registration for Composites Recycling Conference 2020

The American Composites Manufacturers Association (ACMA; Arlington, Va., U.S.)’s Composites Recycling Conference will take place May 19-21, 2020 in Aurora, Colo., U.S. Registration and more information are available on the event website.

The conference program will include:

- sustainability experts and industry leaders with tested, new recycling business solutions,

- sessions and panel discussions featuring industry leaders,

- hands-on access to the latest in recycled composite products with exhibitors from the industry’s top companies,

- an exclusive tour of a manufacturing facility with cutting-edge technologies, energy-efficient composites manufacturing and EOL recycling, and

- cross-industry networking opportunities with an international network of businesses, industry stakeholders and leaders.

AIMPLAS to host 7th International Seminar on Biopolymers and Sustainable Composites

AIMPLAS, the Plastics Technology Centre (Valencia, Spain), will hold the seventh edition of its International Seminar on Biopolymers and Sustainable Composites from March 4-5, 2020. This seminar is aimed at raw material suppliers, processing companies, machinery manufacturers, end users, companies in plastic waste management and treatment, public administrations (regarding environmental policies), research centers, universities and public research bodies.

Discussion topics will include trends in biodegradable plastic materials and plastic materials obtained from renewable sources; innovations in biotechnology and the sustainable waste recovery options offered by these materials; and developments in standardization, certification and life cycle assessment (LCA). Attendees will also hear success stories from leading companies.

In a context of new regulations affecting these materials and heightened consumer interest in buying eco-friendly products, this meeting will encourage discussion of the challenges and opportunities for bioplastics and sustainable composites. More than 20 speakers will talk about key topics in seven sessions during the two-day seminar.

A full agenda and a link to register can be found on the event website.

The event is sponsored by Leistritz, Total Corbion, BIO-FED, NESTE, Quimovil, Kompuestos, Fontier Lab and Waker.

KRÜSS Hosts “Make it stick! A Hands-on Workshop on Adhesion and Surface Preparation”

“Make it stick!,” a workshop for hands-on users of surface analysis and preparation technology, will be presented by KRÜSS USA (Matthews, N.C., U.S.) and its event partners April 7-9, 2020, in Charlotte, N.C., U.S. Professionals in the automotive, aerospace, defense, paint, coatings, composites and plastics industries can take part in this three-day event to learn how to operate the tools and software that are used to analyze and optimize surfaces for improved adhesion.

Participants will experience morning education sessions offered offsite by KRÜSS, along with event partners Adapt Laser, Cold Jet, Enercon and Tantec. Afternoon sessions in the KRÜSS lab will be fully supported, hands-on workstations created around the day’s focus partners and applied to each morning’s topics to make them stick.

Registration is open until March 31, 2020, and can be found on the event website.

Polynt-Reichhold announces gel coat application and repair course

Polynt-Reichhold (Carpentersville, Ill., U.S.) will host a technical training seminar March 11-12, 2020 at its Application Center in North Kansas City, Mo., U.S. This free course will introduce and expand on a working knowledge of gel coat materials, application and repair skills. This course is designed for composite fabricators, production gel coaters and others interested in understanding gel coat application, spray equipment, finishing and repair practices.

Polynt’s Technical Service Specialists in composite materials, processing methods and application equipment will facilitate the workshop conducting classroom tutorials and product hands-on demonstrations. Emphasis will be placed on spray equipment setup and maintenance, including shutdown, startup and troubleshooting.

Find more information on the event website.

SPE Thermoset Division extends paper and abstraction due date for SPE Thermoset TopCon

The Society of Plastics Engineering Thermoset Division (SPE; Danbury, Conn., U.S.) has extended the deadline for paper abstracts for the SPE Thermoset TopCon 2020 event to Feb. 21, 2020. Abstracts should be submitted as soon as possible due to limited availability. Final papers are due March 20, 2020. Abstracts can be sent to teri@intuitgroup.com.

Speakers are invited to attend the event free of charge, as well as OEMs. A variety of exhibit and non-exhibit sponsorship packages offering opportunities for company exposure are available.

The SPE Thermoset TopCon 2020, which takes place May 12-13, 2020 in Madison, Wis., U.S., will feature technical presentations and exhibits highlighting advances in materials, processes, and equipment for thermoset technologies in electrical, automotive, off-highway, appliance, aerospace, building and construction, oil and gas, and other industries.

The conference includes a networking breakfast, lunch and cocktail reception on May 12, and breakfast and a keynote and/or additional sessions in the morning on May 13. Optional social events, including a golf outing at University Ridge Golf Course and a cruise of the Madison shoreline via private yacht with deluxe appetizers and beverages are offered on May 11, the day before the conference begins.

Companies interested in showcasing their products and/or services, and individuals interested in registering to attend the event should go to the event website.

Employment Opportunity: Senior Applications Engineer, Materia

Materia is seeking a Senior Applications Engineer for advanced composites applications.

Materia (Pasadena, Calif., U.S.) is seeking a Senior Applications Engineer to lead the engineering, processing project support and technical project management required for new customers to adopt Materia Proxima resins in advanced composite applications.

Essential Duties and Responsibilities:

- Serve as the engineering expert that supports new customers and development projects for advanced composite applications in major industries using pultrusion, filament winding, and HP-RTM/C-RTM processes.

- Develop process and manufacturing recommendations that enable customer adoption of Materia products.

- Collaborate closely with customer engineering teams to facilitate successful technology transfer and process scaleup.

- Coordinate and execute product trials and demonstrations at customer facilities.

- Work closely with colleagues to make test samples and provide technical feedback needed for developing new or improved resin processes and/or formulations.

- Maintain careful records, produce reports and other documents to meet technology dissemination, patent protection, and/or quality control needs.

- Work with colleagues to manage and maintain facility organization and safety.

Qualifications and Experience:

Education

- B.S. in engineering, material science or similar. Consideration will also be given to qualified individuals with a Certified Composites Technician Degree (CCT).

Experience

- 7+ years of relevant technical experience.

- Thorough understanding and experience with pultrusion processes and equipment for liquid thermoset resins is preferred; experience with HP-RTM, C-RTM and filament winding is a plus.

- Prior experience with direct customer interactions in a technical role

- Demonstrated technical problem-solving ability.

- Significant hands on experience and technical background related to working in laboratories and/or manufacturing environments.

- Strong oral and written communication skills.

- Good project and time management skills.

- Travel requirement: 25-50% expected (domestic and international).

- Location: Pasadena, Calif., U.S.

To submit an application, visit https://materiainc.applicantpro.com.

Related Content

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreMaterials & Processes: Fibers for composites

The structural properties of composite materials are derived primarily from the fiber reinforcement. Fiber types, their manufacture, their uses and the end-market applications in which they find most use are described.

Read MoreA new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read MoreMaterials & Processes: Resin matrices for composites

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.

Read MoreRead Next

Composites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read More

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)