CompositesWorld News for Dec. 02, 2019

Read news from Anisoprint, Roth Composite Machinery, and ACMA - American Composites Manufacturers Association

FACC receives FAA STC approval for its Passenger Luggage Space Upgrade

U.S. airlines can retrofit A320 family aircraft with modified storage compartments said to enable 67% more storage space at reduced weight.

Source | FACC

FACC (Innkreis, Austria) has been issued a supplemental type certificate (STC) by the U.S. Federal Aviation Administration (FAA) for its Passenger Luggage Space Upgrade, which will be made available to airlines as a retrofit for the A320 aircraft family. The upgrade, which was developed by FACC’s EASA Part 21 J Design Organisation, enables airlines to offer passengers more stowage space for hand luggage. The company says the new FAA certification will enable it to further increase its aftermarket service activities in the American market.

“The FAA’s STC certification clearly opens up new opportunities for operators of A318, A319, A320 and A321 aircraft,” says Robert Machtlinger, CEO of FACC. “In order to save both money and time, more and more passengers are opting to travel with hand luggage only. As a technology partner to the aerospace industry, FACC is responding to this trend by now also offering American airlines in addition to European airlines a retrofit package that offers more luggage stowage space and thus added comfort for passengers.”

Issued on Nov. 13, the STC issued by the FAA is based on the European Aviation Safety Agency (EASA) STC approval issued earlier this year, which enabled FACC to carry out significant modifications to aircraft using a component developed by its design organization.

By equipping overhead stowage compartments with new, larger doors, FACC says it is able to increase the stowage space for hand luggage by 67% while also reducing weight. The modified overhead stowage compartments can now fit up to five hand luggage cases instead of just three. The newly designed cabin doors are also said to offer airlines a wide range of customization and branding options.

“Passengers appreciate simpler and more convenient handling along with shorter boarding times, while aircraft operators see a big advantage in the smoother boarding process and a reduced workload for the cabin crew in addition to the more modern appearance. Additional benefits include shorter boarding times, fewer delays and, as a result, cost savings during flight operations,” says Christian Mundigler, vice president of FACC Aftermarket Services.

Aircraft retrofits can either be performed by the airlines themselves or by external maintenance companies, with FACC accompanying the initial installation process within the framework of a training program. Depending on the type of aircraft, the installation only takes 7-9 hours, FACC says.

“… The fleets of U.S. airlines currently comprise up to 1,000 A320 aircraft with classic cabins on board. We consider this a great opportunity for our cabin upgrade. Our top priority is, as always, to optimally fulfill the requirements of our customers,” says Mundigler.

Offshore wind expands in Europe, Japan and, potentially, in the Northeast U.S.

Hundreds of offshore turbines will be installed in Europe and Asia, but the U.S. falls behind waiting on a green light from the government.

Source | Siemens Gamesa Renewable Energy

Vattenfall offshore wind farm to use 140 new 11 MW Siemens Gamesa turbines

Siemens Gamesa Renewable Energy (SGRE, Zamudio, Vizcaya, Spain) and Vattenfall (Solna, Sweden) extend turbine supply to cover the entire Hollandse Kust Zuid (HKZ) wind farm zone, making this the largest turbine collaboration to date for Vattenfall, which is the launch customer for Siemens Gamesa’s most powerful 11-megawatt offshore wind turbine. These HKZ turbines, to be installed by 2022 and fully operational by 2023, will supply up to three million Dutch households with power and enable the world’s first subsidy-free offshore wind power project.

The HKZ wind farm zone is planned to be fitted with approximately 140 units of SGRE’s upgraded version of its Direct Drive offshore wind turbine, which now features the ability to reach a capacity of 11 megawatts. This capacity upgrade, available under certain site conditions, means that fewer turbines are needed to generate the same amount of energy. This will reduce installation, operations and maintenance costs and thereby contribute to further reductions in Levelized Cost of Energy for offshore wind. SGRE has over 3,490 offshore wind turbines in operation globally, as of Sept. 2019, with a combined capacity of more than 15.2 gigawatts.

Vattenfall is a leading energy company owned by the Swedish state with operations mainly in Sweden, Germany, the Netherlands, Denmark and the U.K. It has committed to make fossil-free living possible within one generation, and already inaugurated in Aug. 2019 the largest Scandinavian offshore wind farm, Horns Rev 3. With 49 wind turbines installed 25-40 kilometers off Denmark’s west coast in the North Sea, Horns Rev will increase Danish wind power production by 12%, enough to cover the yearly consumption of 425,000 Danish households.

MHI Vestas turbine on floating platform. Source | MHI Vestas

MHI Vestas turbines to power French floating offshore power project plus Japanese wind farm

Eoliennes Flottantes du golfe du Lion (EFGL) will use three MHI Vestas (Aarhus, Denmark) V164-10.0 megawatt turbines for a 30-megawatt pilot project 16 kilometers off the coast of Leucate and Le Barcares in southern France. Developed by a consortium including Engie and EDP Renewables, the Vestas turbines will sit atop the semi-submersible WindFloat platform from Principle Power Inc. This project is a continuation of the successful partnership between EDP Renewables, Engie and MHI Vestas from the WindFloat Atlantic project, which is currently being installed in Portugal. EFGL is the fifth floating offshore wind project in line for MHI Vestas, following WindFloat 1, Windfloat Atlantic, Kincardine and Groix & Belle Ile.

MHI Vestas in the Floating Offshore Wind Sector

The company’s projected installed base as of 2022 is 14 turbines, at 134 megawatts. It has five projects to date:

- WindFloat 1 (Portugal) – 1 x V80-2.0 megawatts installed in 2011 (decommissioned)

- WindFloat Atlantic (Portugal) – 3 x V164-8.4 megawatts (currently being installed)

- Kincadine (Scotland) – 5 x V164-9.5 megawatts (installed in 2020)

- Groix & Belle Ile (France) – 3 x V164-9.5 megawatts (planned installation in 2022)

- EFGL (France) – 3 x V164-10.0 megawatts (planned installation in 2022)

MHI Vestas will also supply its V174-9.5 megawatt turbines for the 220-megawatt Hibikinada Offshore Wind Farm. This is the first awarded, commercial-scale project to be announced in Japan and a strong signal that the Japanese offshore wind market is beginning rapid development.

The V174-9.5 megawatt turbine will also be used for the 257-megawatt Baltic Sea project. MHI Vestas has signed a conditional agreement with Parkwind to supply 27 turbines for the Arcadis Ost 1 wind farm in the German Baltic Sea. Scheduled for installation in late 2022, this project is located 20 kilometers northeast of the island of Rugen and will supply power for 300,000 German homes. Due to challenging subsea soil conditions, a floating installation method is planned, promising further cost reduction in the industry and the potential to unlock many offshore areas around the world with challenging subsea soil conditions.

Source | Shizen Energy

Northland Power and Shizen Energy set up joint venture for offshore wind in Japan

Northland Power Inc. (Toronto, Ontario, Canada) has announced an agreement with Shizen Energy Inc. (Fukuoka City, Japan) to establish Chiba Offshore Wind Inc., a 50:50 joint venture, for development of 600 megawatts of offshore wind projects in Chiba Prefecture, Japan.

Japan’s offshore wind market is gaining momentum following the government’s commitment to increase the deployment of renewables and the passing of the legislation that supports large-scale offshore wind development areas. The Japanese government issued an updated Energy Supply Plan in July 2018, targeting 10 gigawatts of wind capacity (offshore and onshore) by 2030 as part of its ambition to reach a 22-24% renewable share of electricity generation by 2030.

Northland Power is a global developer, owner and operator of sustainable infrastructure assets with over 30 years of experience, a global fleet of assets generating more than 2.4 gigwatts and operating facilities in Canada, Latin America, and Europe. It has a project pipeline of 1.4-plus gigawatts under construction and advanced development, including Asia, where it owns a 60% equity stake in the 1,044-megawatt Hai Long project under development in Taiwan.

Shizen Energy has contributed to the development of approximately 1 gigawatt of renewable energy in Japan and is expanding its portfolio in both offshore wind and global installations, including a solar plant in Brazil and wind and solar projects in Vietnam and Thailand.

New Jersey boosts offshore wind target to 7.5 GW by 2035

New Jersey Governor Phil Murphy has signed Executive Order No. 92, increasing New Jersey’s offshore wind goal from 3,500 megawatts of offshore wind-generated electricity by 2030 to 7,500 megawatts by 2035. This will help New Jersey meet its goals of reaching 50% renewable energy by 2030 and a 100% clean energy economy by 2050.

“There is no other renewable energy resource that provides us with either the electric-generation or economic-growth potential of offshore wind,” said Murphy. “When we reach our goal of 7,500 megawatts, New Jersey’s offshore wind infrastructure will generate electricity to power more than 3.2 million homes and meet fifty percent of our state’s electric power need. Our offshore wind industry will generate billions of dollars in investments in New Jersey’s future that will, in turn, create thousands of jobs.”

“Currently, East Coast states have contracted a combined 8,240 megawatts of offshore wind electricity generation,” says Liz Burdock, CEO and president of the Business Network for Offshore Wind. “These projects are currently under development and will have ‘steel in the water’ by 2026. There is no doubt that the U.S. offshore wind industry is moving forward because of strong State leadership and commitment.”

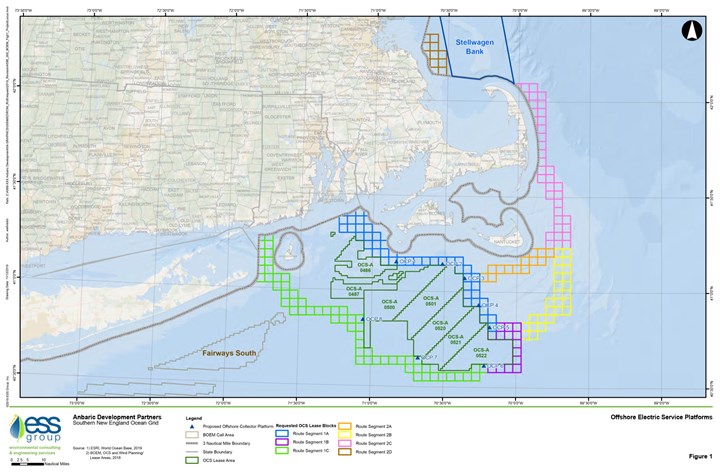

Source | Anbaric

Anbaric to construct OceanGrid for offshore wind to replace fossils fuels as foundation of New England’s electric system

Anbaric (Wakefield, Mass., U.S.) has filed an application with the Bureau of Ocean Energy Management (BOEM) to develop the Southern New England OceanGrid — an independent, open-access offshore transmission network on the outer continental shelf that would link the existing wind lease areas via a common system and deliver that power to the on-shore grid.

The Southern New England OceanGrid would be developed in phases and anticipates an offshore transmission network connecting up to 16,000 megawatts of offshore wind to Massachusetts, Rhode Island and Connecticut. Additionally, it includes transmission line routes that connect BOEM lease areas directly into Boston, Rhode Island’s Narragansett Bay, Massachusetts’ South Coast and Connecticut to provide offshore wind-generated electricity to area residents. Built out over a period of 20 years, the Southern New England OceanGrid provides the infrastructure for a clean energy resource that will replace fossil fuels as the foundation of New England’s electric system.

Offshore Wind: ‘If We Blow It, We Won’t Catch Up’

In a Nov 2019 North American Windpower article, author Michael Bates reports that other countries are sprinting ahead of the U.S. in offshore wind, citing findings from a new report, Offshore Wind Outlook 2019.

He notes that the offshore industry in Europe is slated to grow 600-900% over the next 20 years, and possibly even more if offshore-generated electricity is used to create hydrogen fuel, as Vattenfall has already begun to do in Sweden.

China will become the country with the most offshore wind generation within five years, and its offshore industry is expected to grow by at least a factor of 25 over the next 20 years. In contrast, the U.S. industry is awaiting a green light from regulators, as well as more grid infrastructure. Note the above application by Anbaric to the U.S. Bureau of Ocean Energy Management (BOEM).

“The U.S. has to forge ahead or lose ground,” says Liz Burdock, CEO and president of the Business Network for Offshore Wind. “The states are doing everything they can to make offshore wind happen. It’s up to the federal government to act now, and provide the industry with regulatory certainty. We’re at a critical moment, and if we blow it, we won’t catch up.”

“The United States has a pipeline that exceeds Europe’s present deployment,” Burdock notes. “Once the offshore wind supply chain is underway and truly producing in the USA, we have the opportunity to supply and export to this trillion-dollar market.

Anisoprint launches ProM IS 500 industrial 3D printer

ProM IS 500 is said to be the first industrial printer for continuous fiber-reinforced high-temperature plastics.

Anisoprint (Moscow, Russia) has launched the ProM IS 500, which it claims is the first industrial 3D printer specifically designed to print high-temperature thermoplastics with continuous fiber reinforcement.

The ProM IS 500 reportedly provides precise, repeatable and reliable manufacturing of mid-sized composite parts with a build volume of 600 by 420 by 300 millimeters. The ProM IS 500 is equipped with a heated chamber for printing high-temperature polymers such as polyetheretherketone (PEEK) or polyethylenimine (PEI), and also features automated calibration, material and print quality controls and high-precision motion control, supporting industrial interfaces and safety requirements. The machine is designed to run 24/7 in a factory environment.

This new product is based on Anisoprint’s patented Composite Fiber Co-extrusion (CFC) technology and represents another step towards the company’s new approach to manufacturing, which exploits the anisotropy of composites (see “Advancing additive manufacturing to exploit anisotropy”). The ProM IS 500 allows for professional-level printing of anistropic composites while its basics can be learned from the company’s desktop continuous fiber 3D printer, Composer, also based on CFC technology.

Anisoprinting technology allows manufacturing of complex-shaped composite parts without tools or molds. Due to the ability to apply fibers in topology-optimized lattices, the maximum properties of unidirectional composites are possible while spending the minimum of material for the expected loads. This significantly reduces weight, production time and part cost. Anisoprint asserts that ProM IS 500 will replace less efficient traditional technologies and materials for manufacturing mid-sized tools, spare parts and functional prototypes for aerospace, automotive, robotics and other industries.

ProM IS 500 will have up to four changeable print heads for printing composites and pure plastic, making it possible to reinforce different zones of the part with different composites (for example, carbon fiber, basalt fiber) depending on the user’s goal and part requirements.

High-temperature plastics such as PEEK and PEI will be available as matrix materials for composites anisoprinted on ProM IS 500. This expands applications for 3D-printed parts into aggressive industrial environments. ProM IS 500 printers will ship beginning from the end of 2020. Pre-orders can be made at https://anisoprint.com/product-prom.

Roth Industries honored at Großer Preis des Mittelstandes

Roth Industries was recently honored for its employee support, capacity for innovation, environmental management and social commitment.

Source | Roth Industries

Roth Industries, parent company of Roth Composite Machinery (Steffenberg, Germany), was recently honored with two awards from the Oskar Patzelt Foundation (Leipzig, Germany), the Großer Preis des Mittelstandes award and a 2019 Honorary Plaque recognizing it as one of the top companies in Germany.

In presenting the Großer Preis des Mittelstandes award at an award ceremony, Helfried Schmidt and Petra Tröger of the Oskar Patskelt Foundation praised the company’s overall performance, including its support of employees, capacity for innovation, environmental management and social commitment. The company was presented with a 2019 Honorary Plaque for its development from a handicraft business into a worldwide leader for floor heating and cooling systems, energy storage systems and composite technologies. The Roth family of companies and Matthias Donges, CEO of Roth Industries, accepted the award.

“This award is a recognition of all that we are doing in the building and industrial technology sectors. The motto of this year’s competition was ‘Sustainable business.’ This underscores our commitment as a medium-sized family company based on our company principles: close-knit, dynamic, responsible. We are dedicating these awards to our employees, on whom the success of our company depends,” says Donges.

ACMA announces 2020 Infrastructure Day

ACMA’s fifth Infrastructure Day in Feb. 2020 will gather political and composites manufacturing leaders in Washington D.C. to discuss infrastructure legislation.

The American Composites Manufacturers Association (ACMA, Arlington, Va., U.S.) will host the fifth annual Infrastructure Day on Feb. 12-13, 2020, on Capitol Hill in Washington, D.C.

According to ACMA, 2020 Infrastructure Day will allow attendees to better understand the political landscape, to gain insights about how to open key federally influenced infrastructure markets, and to learn new skills for effective lobbying for legislation such as the NIST Composites Standards Act and the IMAGINE Act. The NIST Composites Standards passage of the NIST Bill will inject $11 million of research to model composites durability. Passage of the IMAGINE Act will create a combined $650 million pot of money that can be used by asset owners (states, cities) for innovative highway and water infrastructure construction.

“The nation's aging infrastructure is top of mind in Washington and around the country. The nation's leaders have noted America needs more than a trillion dollars’ worth of investment to rehabilitate bridges, water systems, dams and the electric grid. Composites are uniquely poised to provide real-world solutions to meet this demand,” says Tom Dobbins, ACMA president.

Throughout the event, leaders from Congress, the White House and federal agencies will attend, present and network with composites business leaders. Attendees will have the opportunity to interface with leaders from:

- the Federal Highway Administration,

- Department of Energy,

- Environmental Protection Agency,

- U.S. Army Corps of Engineers,

- Senate Committee on Environment and Public Works,

- Senate Committee on Energy and Natural Resources,

- House Committee on Energy and Commerce,

- House Committee on Transportation and Infrastructure, and

- senators and representatives serving member districts.

To learn more, visit the 2020 Infrastructure Day website.

Related Content

The state of recycled carbon fiber

As the need for carbon fiber rises, can recycling fill the gap?

Read MoreRecycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MoreMaterials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

Read MoreCarbon fiber in pressure vessels for hydrogen

The emerging H2 economy drives tank development for aircraft, ships and gas transport.

Read MoreRead Next

From the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read MoreComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read More

.jpg;maxWidth=300;quality=90)