Composites Evolution introduces Evopreg EPC200 epoxy prepreg

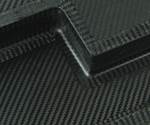

Evopreg EPC200 enables variable temperature cure with good surface finish.

Source | Composites Evolution

Prepreg supplier Composites Evolution (Chesterfield, U.K.) has expanded its Evoprep EPC component epoxy range with the launch of its variable temperature curing prepreg, Evopreg EPC200. Based on a toughened epoxy resin system, the company says it enables curing between 65°C and 120°C when using vacuum bag/oven, out-of-autoclave (OAA) or press-molding processes.

The company notes that Evopreg EPC200 is primarily aimed at fabricators using low-temperature, OOA molding processes who want to produce components with a high-quality surface finish. Composites Evolution also says the epoxy prepreg has a flexible cure profile, which makes it ideal for rapid processing at high temperatures, reducing production time while simultaneously maintaining the same level of performance.

Composites Evolution Evopreg EPC component resins are available in a range of carbon, glass, aramid and ampliTex flax reinforcements.

Related Content

-

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

-

Cycling forward with bike frame materials and processes

Fine-tuning of conventional materials and processes characterizes today’s CFRP bicycle frame manufacturing, whether in the large factories of Asia or at reshored facilities in North America and Europe. Thermoplastic resins and automated processes are on the horizon, though likely years away from high-volume production levels.

-

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.