Cabin Management Systems leverages Markforged carbon fiber 3D printers for FAA-compliant end-use parts

Cabin Management Solutions (CMS) incorporates the Markforged X7 printer and Onyx FR material for high-quality, rapid parts production for cabin management maintenance, upgrades and replacements for luxury aircraft.

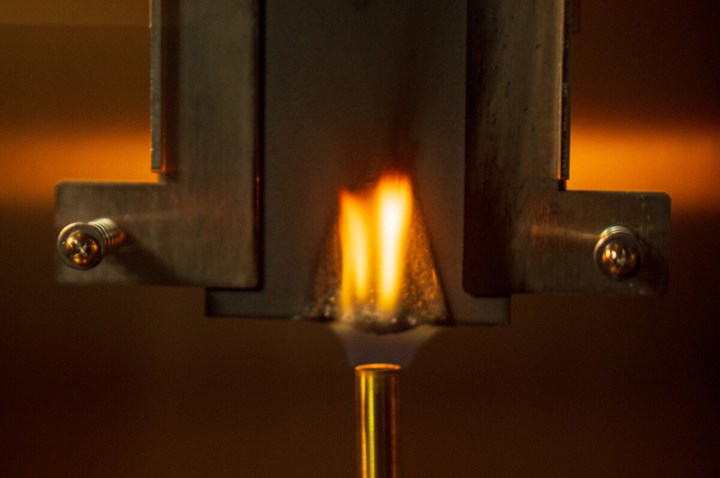

CMS uses Onyx FR to deliver custom parts that are high strength, low weight, and flame retardant. Photo Credit: Markforged, CMS

Markforged (Watertown, Mass., U.S.), creator of the integrated metal and carbon fiber additive manufacturing platform, The Digital Forge, has announced that Cabin Management Solutions (CMS, Conroe, Texas, U.S.), a privately held in-flight cabin management and entertainment systems company, is using two Markforged X7 industrial carbon fiber 3D printers to print high-quality, end-use parts for cabin management maintenance, upgrades and replacements for luxury aircraft.

CMS was founded in 2019 and works frequently with aircraft maintenance, repair and overhaul (MRO) companies and individual aircraft owners to design and develop cabin control and entertainment systems for luxury, private and business jets. CMS uses Onyx FR to fabricate custom parts that are high strength, low weight, flame retardant and FAA compliant. According to Markforged, the X7 printers retain improved the quality and speed of parts production, enabling CMS to complete a higher volume of jobs more quickly and earning it a reputation for fast time to market, high-quality deliverables and rigorous testing and certification process.

“In the aerospace industry, quality and on-the-fly adaptability are crucial to success,” says Jeff Pike, VP of engineering at CMS. “We often have to produce low-volume, high-value parts from scratch which can be time- and labor-intensive. Markforged’s X7 allows us to do this quickly and more efficiently, while ensuring functionality and retaining the upscale aesthetics expected in luxury aircraft.”

On one aircraft in particular, the CMS team printed at least 100 different parts, including approximately 20 light switch panels, a cabin climate controller, latches, release buttons, USB-C and drop-in USB-A chargers and adjustable touch screen brackets — all using the X7 printer. In order to meet the specific demands of its luxury-oriented customers, the CMS team then adds an extra level of customization via overlays that mimic upscale cabin surfaces including gold metal electroplating, wood veneer and more. CMS says its process ensures the end product is FAA compliant while going above and beyond customers’ expectations for aesthetics.

Moving forward, CMS plans to continue leveraging Markforged’s additive solutions, especially with Markforged’s recent release of Onyx FR-A and Carbon Fiber FR-A, aerospace-ready versions of its Onyx FR and Carbon Fiber FR materials. These two new materials come with full material traceability and are undergoing qualification on the Markforged X7 printer via a program conducted by the National Center for Advanced Materials Performance (NCAMP), one of two bodies authorized by the FAA to qualify materials for flight. Once this process is complete, CMS will be able to increase its overall production speed, which will result in adding even more jobs to its already expanding pipeline.

“CMS has incorporated Markforged technology into their business in a way that enables them to maintain their reputation for high-quality and give themselves competitive advantage,” says Markforged President and CEO Shai Terem. “Our technology is not only about printing parts faster and at the point of need, but also giving aerospace manufacturers the confidence that their parts meet the regulatory and functional requirements of their industry.”

To read more about CMS’s use of Markforged printers, visit the company’s website.

Related Content

The making of carbon fiber

A look at the process by which precursor becomes carbon fiber through a careful (and mostly proprietary) manipulation of temperature and tension.

Read MoreThe state of recycled carbon fiber

As the need for carbon fiber rises, can recycling fill the gap?

Read MoreNovel dry tape for liquid molded composites

MTorres seeks to enable next-gen aircraft and open new markets for composites with low-cost, high-permeability tapes and versatile, high-speed production lines.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreRead Next

CW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read MoreComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read More