Bercella, Beamit partner to research composite aerospace, defense applications

The Italy-based companies plan to focus on novel joining methods between additively manufactured and CFRP parts.

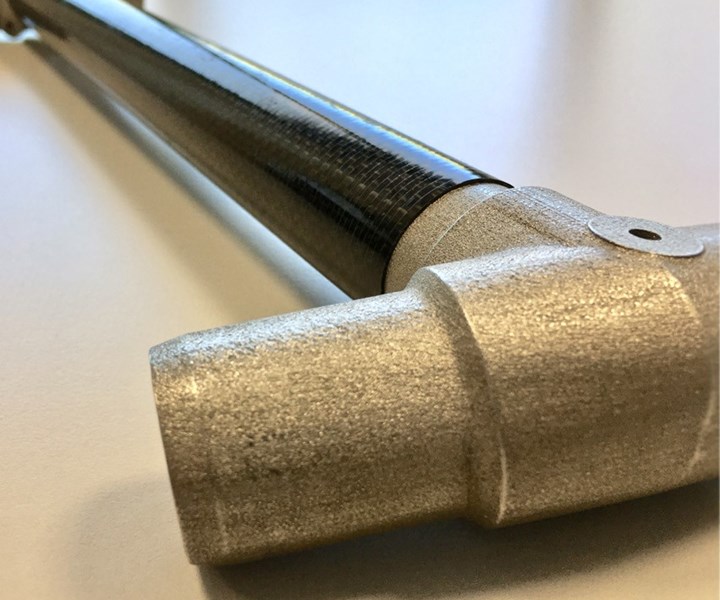

Source | Bercella

Composites specialist Bercella Srl (Varano de’ Melegari, Italy) and additive manufacturing specialist Beamit SpA (Fornovo di Taro, Italy) have announced a strategic partnership to explore joining methods between additively manufactured and carbon fiber-reinforced plastic (CFRP) parts for space, aviation and defense applications.

Both companies provide solutions, ranging from materials development and component qualification, to serial manufacturing, to top OEMs and Tier 1 suppliers. Together, the companies are exploring the potential synergies between the composites and additive manufacturing technologies, with a particular focus on innovative joining methods between AM and CFRP parts.

“We are eager to team-up with Beamit and unlock new potentials for structural optimization,” says Massimo Bercella, CEO of Bercella. “As Italian companies in a territory of excellences, we embrace every challenge determined to succeed. We always find a way, no matter the hassles. And in such a complex time, our common deep roots in the heart of Emilia Romagna will push us to step up driven by a sense of curiosity towards innovation.”

“In Bercella we found a high-professional partner capable to provide leading expertise in composites design and manufacturing for aerospace applications,” says Michele Antolotti, Beamit general manager. “Despite the world economic consequences of the actual pandemic situation, joining forces it’s a strategic way to react and to support high-end companies into their ramp-up of new product development.”

Related Content

-

Materials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

-

Materials & Processes: Fibers for composites

The structural properties of composite materials are derived primarily from the fiber reinforcement. Fiber types, their manufacture, their uses and the end-market applications in which they find most use are described.

-

Novel dry tape for liquid molded composites

MTorres seeks to enable next-gen aircraft and open new markets for composites with low-cost, high-permeability tapes and versatile, high-speed production lines.

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)