Anisoprint launches basalt fiber for continuous-fiber 3D printing

The material is said to be 15 times stronger than plastic, five times lighter than steel and 1.5 times stronger and lighter than aluminum.

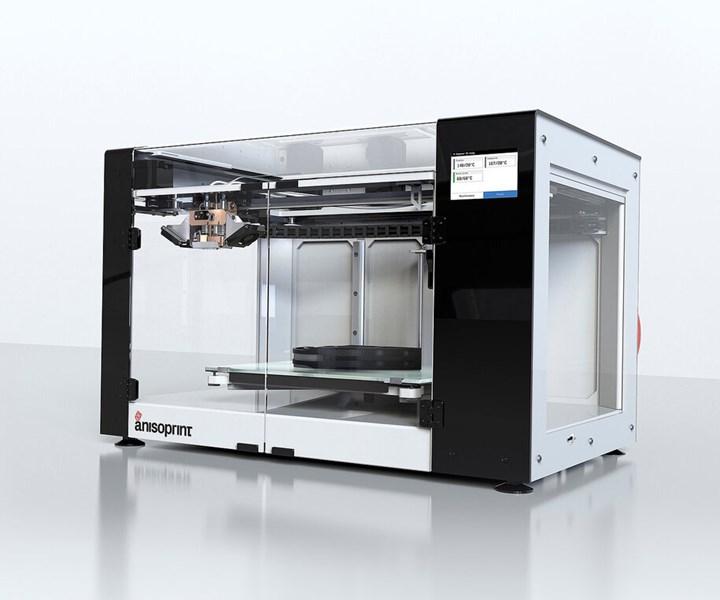

Anisoprint’s basalt fiber composite is available for use with its Composer continuous-fiber 3D printer. Source | Anisoprint

Anisoprint (Esch-sur-Alzette, Luxembourg), a manufacturer of continuous carbon fiber 3D printers and materials, recently launched a basalt fiber composite for use with its 3D printing technology.

According to the company, the material, when applied to its 3D printing technology, is 15 times stronger than plastic, five times lighter than steel, and 1.5 times stronger and lighter than aluminum. It also is said to significantly decreases manufacturing costs.

Since basalt fiber also features radio transparency, Anisoprint says that parts made of its basalt fiber composite do not significantly alter the amplitude and phase of radio-frequency electromagnetic waves transmitted through them, making it an ideal option for non-conductive elements and isolators.

Anisoprint’s technology involves continuous composite fiber coextrusion with thermoplastic polymers and enables variations in fiber direction, volume ratio and material density.

Related Content

-

Daher CARAC TP project advances thermoplastic composites certification approach

New tests, analysis enable databases, models, design guidelines and methodologies, combining materials science with production processes to predict and optimize part performance at temperatures above Tg (≈150-180°C) for wing and engine structures.

-

UniFORM: High-quality, high-complex EV battery enclosures at low cycle times, low tooling costs

Stellantis subsidiary CpK Interior Products Inc. recently completed a design challenge to prove out its vacuum-assisted wet compression molding process for CFRP battery trays.

-

Overair's Butterfly eVTOL prototype to integrate composites-intensive design

Aiming for first flight tests in the latter half of 2023, Overair’s Butterfly aircraft uses Toray carbon fiber/epoxy prepreg strategically to cut weight on its battery-powered, quiet aircraft.

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)