Albany Engineered Composites qualified to build F-35 skins

Albany, already a fabricator of more than 200 parts for the F-35, is now producing wing skins for the F-35A (CTOL variant) Lightning II fighter jet.

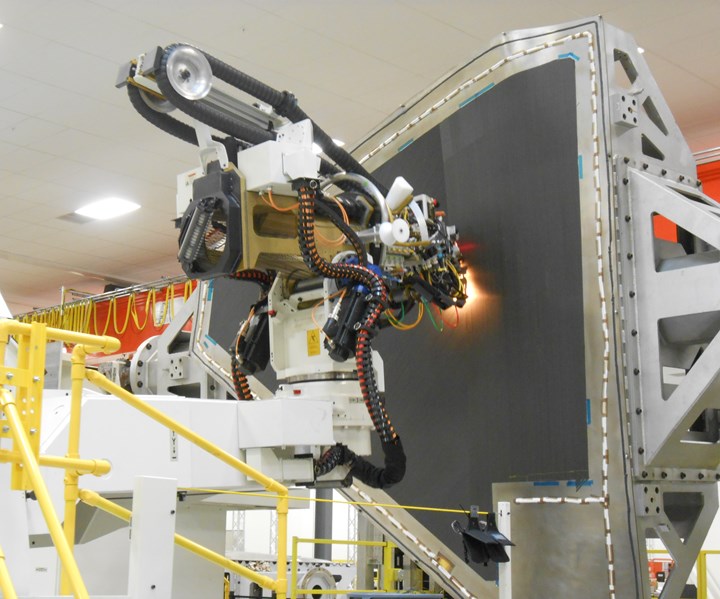

Albany Engineered Composites AFP of F-35 wing skins. Source | Albany Engineered Composites

Albany International Corp. (Rochester, N.H., U.S.) announced on March 2 that its subsidiary, Albany Engineered Composites Inc. (Salt Lake City, Utah, U.S.), has received a contract from Lockheed Martin to manufacture composite wing skins on a state-of-the-art automated fiber placement (AFP) machine at its Salt Lake City operations. As a result of this and several other significant investments in technology and resources, AEC has been awarded a contract to produce wing skins for the F-35A (CTOL variant) of the Lightning II fighter jet. Delivery of production wing skins began in January 2020.

AEC currently fabricates 227 unique parts for the F-35 program, delivering highly engineered products to four customers and five facilities, including international locations. To date, AEC has delivered more than 40,000 parts to support the F-35 program.

“We are very excited to see that a great deal of hard work and investment has been rewarded by our strategic customer Lockheed Martin with additional part numbers and volume beyond our existing successful relationship,” says Greg Harwell, president of Albany Engineered Composites. “We look forward to continuing to develop and deliver advanced composite technologies to the next generation of aircraft,”

Albany International operates 23 plants in 11 countries, employs approximately 4,600 people worldwide, and is listed on the New York Stock Exchange.

Related Content

-

Novel dry tape for liquid molded composites

MTorres seeks to enable next-gen aircraft and open new markets for composites with low-cost, high-permeability tapes and versatile, high-speed production lines.

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.