Airtech 3D-printed resin delivers advanced manufacturing capabilities to U.K. defense sector

Carbon fiber-reinforced, PEI-based Dahltram I-350CF resin system enables production of high-temperature mold tooling for next-gen combat air demonstrator.

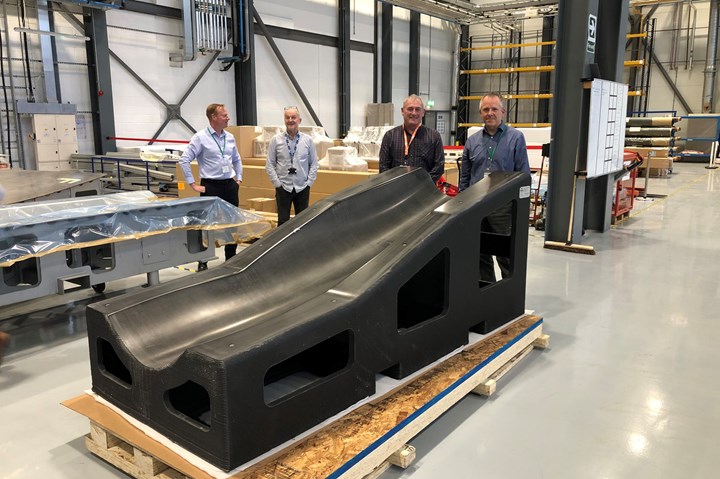

3D-printed tool. Photo Credit: BAE Systems.

BAE Systems (Farnborough, U.K.) reported on May 20 that it is using large-scale 3D printing to produce high-temperature mold tooling using Airtech’s (Huntington Beach, Calif., U.S.) Dahltram I-350CF resin for the production of a future combat air demonstrator.

Dahltram I-350CF system is a high-temperature capable, carbon fiber-reinforced, PEI-based 3D print resin, which has been adopted by the aerospace industry. BAE Systems says it has been working on the development of the manufacturing process with Airtech Advanced Materials Group and Ingersoll Machine Tools, Inc. (Rockford, Ill., U.S.) which printed the mold tool on its MasterPrint large-format 3D printing platform.

The Dahltram range of resins are suitable for multiple print platforms, providing production flexibility with end-use material approvals. Airtech has been able to demonstrate technology readiness and manufacturing readiness with its Dahltram range of resins and its own in-house tooling 3D print service. Continuous thermal cycle testing, pressure leak testing, laser surface scanning and contact material testing have reportedly generated data supporting more than 250 autoclave cycles, without degradation of the Dahltram manufactured tooling. Airtech Advanced Materials Group also has Dahltram Additive Manufacturing Resins and Print-Tech large-scale 3D-printed tool manufacturing capability in the U.S. and Europe.

Related Content

-

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

-

Price, performance, protection: EV battery enclosures, Part 1

Composite technologies are growing in use as suppliers continue efforts to meet more demanding requirements for EV battery enclosures.

-

Materials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

.jpg;maxWidth=300;quality=90)