NDI

Photothermal tomography system enhances composites NDT

JEC World 2024: Austria-based voidsy GmbH introduces the 3D V-ROX system, facilitating fast, contactless and nondestructive inspection with added efficiency and safety.

Grace Nehls

Senior Managing Editor, CompositesWorld

Nondestructive inspection methods available to composites manufacturers

An overview of composite laminate inspection techniques ranging from manual testing methods to more advanced, noncontact options.

Read MorePortable digital ultrasonic imaging achieves in-service, field and manufacturing inspection

CAMX 2023: 2D array ultrasonic NDT for composites, metals and other materials is made possible through Dolpitech’s dolphicam and dolphicam2+ matrix transducer technology.

Read MoreAcoustic imaging enables vacuum leak detection

CAMX 2023: Distran is demonstrating how its ultrasonic camera technology rapidly locates leaks during the vacuum bagging process, and reconstructs their position in real time.

Read MoreInfrared NDT well-suited to demanding in-service, manufacturing and research applications

CAMX 2023: High-precision, cost-effective thermographic NDT technologies offered by Thermal Wave Imaging addresses real-world inspection challenges.

Read MoreRobotic inspection systems maintain process efficiency, productivity

CAMX 2023: Matec Instrument Companies highlights its strong commitment to integrate automation technologies into its nondestructive ultrasonic testing equipment for increased scalability, flexibility, quality and consistency.

Read MoreNDT inspection services, automated systems serve aerospace needs

CAMX 2023: Arcadia Aerospace Industries demonstrates its commitment to navigating the rapidly changing aerospace manufacturing landscape with robotic-based machines and motion control systems, certified facilities for NDT services and conducted training and recruitment.

Read MoreAutomated robotic NDT enhances capabilities for composites

Kineco Kaman Composites India uses a bespoke Fill Accubot ultrasonic testing system to boost inspection efficiency and productivity.

Stewart Mitchell

Contributor writer

Machine, equipment investment strengthens Ruckus Composites’ research, innovation

CNC services expansion, universal testing machines and advanced inspection enable Ruckus to delve deeper into the study and evaluation of carbon fiber damage, as well as nondestructive and destructive testing.

Read MoreUTComp authors bulletin on fitness-for-service assessment of FRP

Welding Research Council (WRC) Bulletin 601 provides technical background and validation for quantitative nondestructive testing methodology for FRP composite equipment.

Read MoreLoop Technology develops robotic arm for wing box inspection

Part of an R&D project with Spirit AeroSystems, the seven-axis Bravura robotic arm automates inspection and sealing within small spaces like aircraft wing boxes.

Read MoreEvident wind blade inspection system automates nondestructive ultrasonic testing

An autonomous, cobot-mounted inspection system combines Industry 4.0 with established ultrasonic technology to rapidly provide repeatable, accurate data and improve overall efficiency.

Read MoreMoviTHERM opens in-house NDT lab

New inspection techniques, excitation sources and infrared cameras enhance feasibility study capabilities for customers in the composites industry.

Read MoreCAMX 2022 exhibit preview: Innerspec Technologies

Taurus and Camus 3D ultrasonic inspection systems provide automated and semi-automated solutions for composite aerospace components.

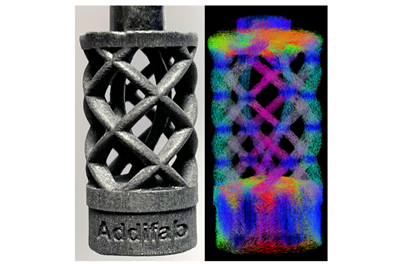

Read MoreXnovo Technology, Exciscope introduce X-ray tensor tomography technique

Through a strategic partnership, the companies introduce the FiberScanner3D module, dedicated to bringing more rapid, reliable and robust fiber structure characterization methods to lab settings.

Grace Nehls

Senior Managing Editor, CompositesWorld

Twenco develops sensors for smart molds and process control in resin infusion and composites welding

Non-invasive DEA and NDT Analyzer for multi-parameter monitoring, QA and control, including real time simulation feed and 3D process visualization across and through composite parts.

Read MoreDolphicam2 NDT system identifies flaws in CFRP panel in one setup

A second benchmark study on a CFRP NDI Proficiency specimen 1A assesses NDT equipment and personnel, successfully characterizes all flaws in panel.

Read MoreNCMS report demonstrates thermography innovations for enhanced NDI capabilities

Technology brief highlights how thermographic signal reconstruction (TSR) has enhanced the readiness of aircraft in less time and at lower cost, with potential for use inspecting composites and metals.

Read MoreDolphitech capability study benchmarks dolphicam2 NDT platform

A CFRP panel was manufactured to the specification of an FAA NDI Proficiency specimen 2A, representative of composite laminates found on commercial aircraft.

Read MoreLaser bondline inspection becomes reality

One of the Holy Grails of composites manufacturing has been reliable verification of adhesive bondline strength integrity. A technology that does just that has arrived.

Read MoreNCC sensor technology unlocks digital potential for liquid resin processes

Research and testing of dielectric sensors performed by the NCC, Meggitt and Cranfield University accurately captures resin infusion data, shows promise for composites manufacturing.

Read MoreInnovation in ultrasonic inspection and nondestructive testing

With increasingly complex structural components working their way into aerospace programs, the need for versatility in inspection and testing capabilities is growing.

Scott Francis

Editor-In-Chief, Gardner Business Media

How ultrasonic testing can find flaws in composite materials

As composite applications expand, so does the demand for more capable inspection systems. Ultrasound has proven to be effective when it comes to in-depth, sophisticated testing.

Read MoreDolphitech releases MxTTU digital scanning solution

In-service inspection capabilities are made more robust, flexible and portable, with the ability to precisely diagnose a larger inspection area and inspects materials that hinder sound propagation.

Read MoreNondestructive testing technologies handle demanding inspection environments

Zetec phased array ultrasonic testing (PAUT) inspection products Emerald and Topaz feature real-time TFM capabilities, more detailed inspection results and improved performance.

Read MoreDesigning for automated composites manufacturing of low-volume aerostructures

The commercial aerospace industry is heavily focused on design for efficient high-rate manufacturing, but there is still need for automated, affordable fabrication of low-rate aerostructures.

Read MoreCAMX 2021 Show Daily highlights composite technology innovations

As the CAMX media sponsor, CompositesWorld reported on several new or improved developments on display, from CAMX Award and ACE Award winners, to the keynote speaker and interesting technologies.

Read MoreWaygate Technologies launches fully connected ultrasonic flaw detector

The customizable, handheld Krautkrämer USM 100 sets new standards in ergonomics, connectivity and ruggedness for composites inspection requirements, such as complex wave propagation and high attenuation.

Read More

.jpg;maxWidth=300;quality=90)