Design and Testing Column

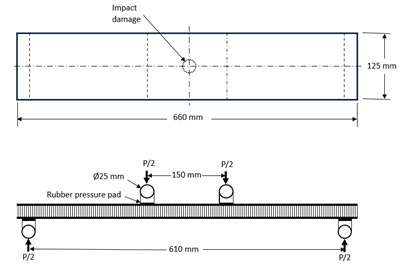

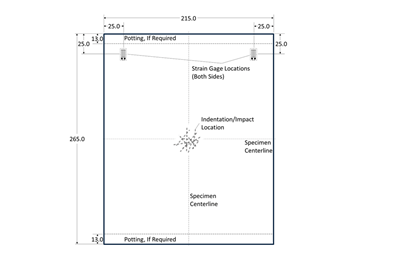

Damage tolerance testing of sandwich composites: The sandwich flexure-after-impact (FAI) test

A second new ASTM-standardized test method assesses the damage tolerance of sandwich composites under flexural loading.

Daniel Adams

Interlaminar tensile testing of composites: An update

New test method developments for measuring interlaminar tensile strength address difficulties associated with the ASTM D6415 curved beam flexure and ASTM D7291 flatwise tensile tests.

Read MoreComposite test methods (and specifications) for fiber-reinforced concrete structures

While initially focused on transitioning existing standards published by the American Concrete Institute, the relatively new ASTM Subcommittee D30.10 is developing new standardized test methods and material specifications for FRP composites.

Read MoreNotched testing of sandwich composites: The sandwich open-hole flexure test

A second new test method has been standardized by ASTM for determining notch sensitivity of sandwich composites.

Read MoreMeasuring ply-wise deformation during consolidation using embedded sensors

Strip-type shape sensor method claims real-time measurement of ply-wise deformation.

Read MoreNotched testing of sandwich composites: The sandwich open-hole compression test

A new ASTM-standardized open-hole compression test method seeks to determine the notch sensitivity of sandwich composites.

Read MoreMaterial equivalence testing in shared composites databases

In response to traditionally proprietary polymer matrix composites (PMC) qualifications, NCAMP continues its efforts to make material property databases publicly available.

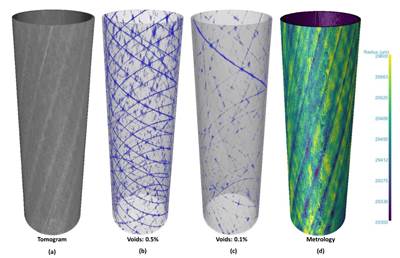

Read MoreMulti-scale 3D CT imaging enables digital twinning, high-fidelity simulation of composite structures

Computed tomography (CT) provides highly accurate 3D analysis of internal microstructure, performance simulation of carbon fiber/PEEK satellite strut.

Glass-coated magnetic microwires for nondestructive composites monitoring

Glass-coated, amorphous microwires combine nanometer to micrometer diameters, enabling embedding into composites without degrading mechanical properties.

Read MoreComposite prepreg tack testing

A recently standardized prepreg tack test method has been developed for use in material selection, quality control and adjusting cure process parameters for automated layup processes.

Read MoreImproving analyses of composite pressure vessels

Accurate geometry modeling and equivalent material property approximations captured by WoundSim will play a role in improving COPV analyses.

Read MoreDetermining the equivalency of composite test methods

While time consuming and somewhat subjective, the comparative assessment approach has been proven effective toward assessing composites test method equivalence.

Read MoreComposites testing as part of a building block approach, Part 2: Upper building block levels

Testing under the upper levels of the building block approach for composites design depends on the structure’s application and complexity.

Read MoreModel-driven design and analysis for sustainable lightweight design

Fraunhofer IGCV uses graph-based design language for fast creation of design variants and simultaneous evaluation of ecological and economic performance along the entire life cycle.

Read MoreDamage tolerance testing of sandwich composites: The sandwich CAI test

A new ASTM-standardized test method established in 2022 assesses the compression-loaded damage tolerance of sandwich composites.

Daniel Adams

Using machine learning to accelerate composites processing simulation

A speed gain of 1,000 to 10,000 times greater than traditional FE models has been achieved using machine learning models, enabling near real-time simulation for large composite components.

Read MoreComposites testing as part of a building block approach, Part 1: Coupon-level testing

The building block materials testing approach is a step-by-step process that serves as a framework for designing composite structures while also reducing risk and cost.

Read MoreComposite testing challenges, Part 3: Testing systems

Several factors need to be considered for accurate and efficient composites testing, including testing systems that can accommodate required test environments, alignment and offer intuitive software.

Read MoreComposite testing challenges, Part 2: Strain measurement for the mechanical testing of composites

Recent developments in contact and noncontact strain measurement methods offer similar performance with additional benefits for composite material testing.

Read MoreComposite testing challenges, Part 1: Introduction to mechanical testing of composites

A range of standardized mechanical tests for complex composites are available and still under development for materials development, design and quality control requirements.

Read MoreDurability testing of adhesively bonded composites

Current test method development shows potential for the composite wedge test, a standardized durability-based test for adhesively bonded composites.

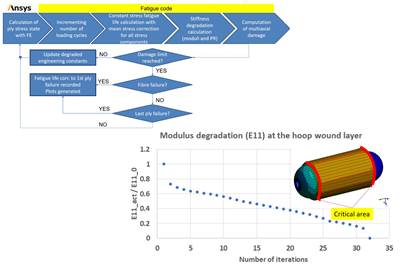

Read MoreNumerical tool with mean stress correction demonstrated for fatigue life estimation of thermoplastic composites

To aid design of fatigue-resistant structures, Econ Engineering has developed an algorithm to evaluate ply-based cyclic stiffness degradation combined with an FE failure check, validated for a CF/PAEK pressure vessel.

Fatigue testing of composites

Fatigue testing may be performed at multiple points during the design of a composite structure. A focus on small-specimen level fatigue test methods, however, suggests a need for more testing method standardization.

Read MorePart 2: Applying CT scan data analysis and visualization to composites

Advanced CT-scan analyses can offer deep insight into challenges faced when examining novel composites and hybrid material behavior or performing quality and certification testing. Part two of a two-part series.

Read MoreApplying CT scan data analysis and visualization to composites

Imaging and analysis via computed tomography (CT) has potential for certifiable safety and business sustainability and could be key for interior inspections of composite parts. Part 1 of a two-part series.

Read MoreDevelopment of ASTM standards for composites: An insider’s perspective

According to Dan Adams’ inside perspective, two elements determine whether a proposed test method for composite materials becomes an ASTM standard.

Read MoreFASTIGUE: Empowering digital twins of large-scale composite structures

A 3D finite element technique to resolve the fidelity-versus-speed dilemma of performing fatigue analysis for large composite structures.

Read MoreFlexure testing of sandwich composites

Dan Adams assesses the facesheet or core failures for three-point and four-points flexural loading configurations.

Read More