Past, Present and Future

Creating a culture of excellence in aerocomposites

ST Engineering MRAS discusses the importance of addressing human factors to reduce separator inclusion in bonded structures.

Read MoreComposites opportunities in eVTOLs

As eVTOL OEMs seek to advance program certification, production scale-up and lightweighting, AAM’s penetration into the composites market is moving on an upward trajectory.

Read MoreOpportunities and challenges for composites in electric vehicles

Polymer and material specialists at chemical consulting firm ChemBizR reflect on the role of composites in current and future efforts to make electric vehicles more efficient — and more attractive for consumers.

Read MoreAugmenting engineered thermoplastics with natural fibers

The Paris Climate Accord mandate for net-zero carbon by 2050 has kick-started an innovation revolution for natural fibers and sustainably engineered resins.

Read MoreFrom sailplanes to composites repair: Growing composite training opportunities over the years

Mike Hoke discovered his interest in the composites industry at a young age. His journey eventually led him to Abaris Training Resources, which he owned and evolved for more than 30 years.

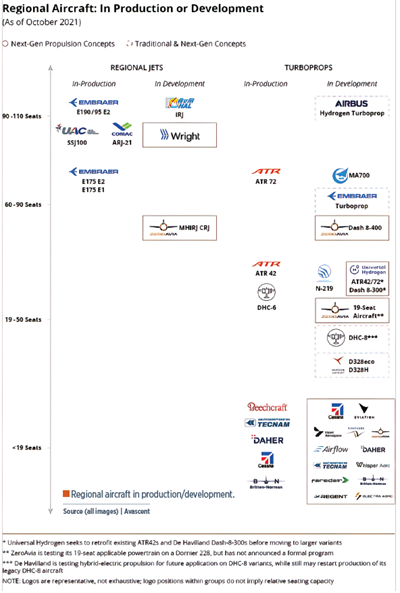

Read MoreRegional air mobility: A meaningful first step in the electric aviation revolution

Electrification of fixed-wing, <50-seat regional aircraft might stimulate a new era of growth that could help pave the way for advanced air mobility (AAM) aircraft.

Read MoreSetting unrealistic expectations in composites manufacturing

In the aerospace composites industry, quality comes at a cost, but built-in incentives throughout the supply chain don’t always favor the best and the brightest.

Read MoreThe compelling argument for expanded use of carbon fiber composites

Contributing columnists from Aramco explain that decreasing carbon fiber prices and continued innovations may allow carbon fiber composites to expand into new markets, including increased use in oil and gas applications.

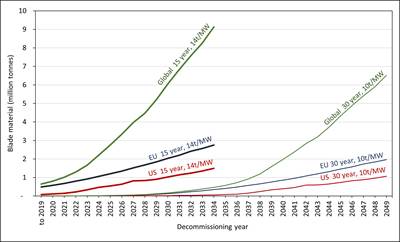

Read MoreDefining the landscape for wind blades at the end of service life

There is a generation of wind turbine blades at or near the end of their useful life. Disposing of them, recycling them or reusing them requires a better understanding of the blade end-of-life landscape.

Read MoreBest practices in the CNC machining of composites

Machining composite materials is a challenging task. Proper tool selection, machine settings and process innovations help make it manageable.

Read More