Clean Sky

Fraunhofer IWS completes MFFD longitudinal fuselage joint using CONTIjoin technology

Thermoplastic composite upper and lower half shells for the Multifunctional Fuselage Demonstrator were welded using CO2 laser over a total length of 8 meters.

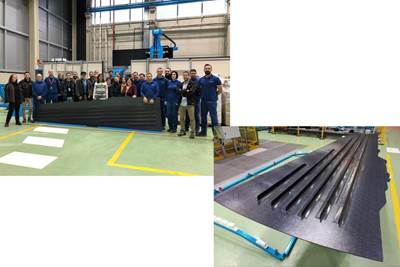

Read MoreClean Sky 2 OUTCOME project demonstrates PEEK thermoplastic composite wingbox cover

Airbus Defense and Space, FIDAMC and Aernnova demonstrate out-of-autoclave, one-shot process for wingbox cover with integrated stringers for regional aircraft.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreThe state of recycled carbon fiber

As the need for carbon fiber rises, can recycling fill the gap?

Read MoreThermoplastic composites welding advances for more sustainable airframes

Multiple demonstrators help various welding technologies approach TRL 6 in the quest for lighter weight, lower cost.

Read MoreCarbon fiber in pressure vessels for hydrogen

The emerging H2 economy drives tank development for aircraft, ships and gas transport.

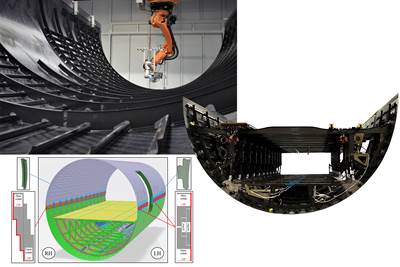

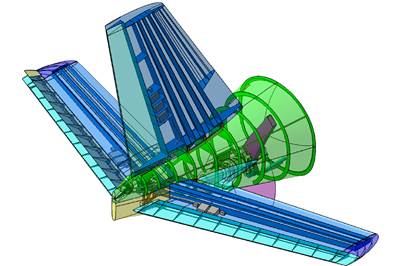

Read MoreMulti-flange RTM frames enable radical rear fuselage design

The Clean Sky 2 Advanced Rear End (ARE) demonstrator combines patented new frame design, thermoset and thermoplastic composites and smart tooling to advance aircraft design and cut weight, cost and production time.

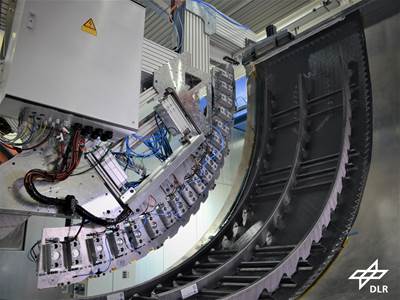

WatchDLR Augsburg integrates sixth frame to upper half fuselage test shell for MFFD

Clean Sky 2 thermoplastic composite demonstrator advances toward full assembly.

Read MoreAirbus C295 technology demonstrator makes maiden flight, proves novel design, manufacturing processes

C295 Flight Test Bed 2 (FTB2) tests OOA composite semi-morphing wing, flaps and flap tabs, as well as SatCom antenna for future turboprop aircraft.

Read More