Automation

Broetje-Automation presents automated sealing solutions for aerocomposites

Versatile and precise system options, whether semi- or fully automated, can be tailored to individual process requirements for composite or metallic materials, ultimately reducing process steps, labor hours and cost.

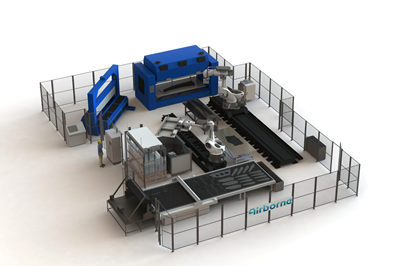

Read MoreAirborne to deliver automated preforming line to GKN Aerospace

Automated cell combines ply placement, preform trimming, a ply cutter and a hot drape former for 3D preform production, to be initially deployed to fulfill ASCEND project objectives.

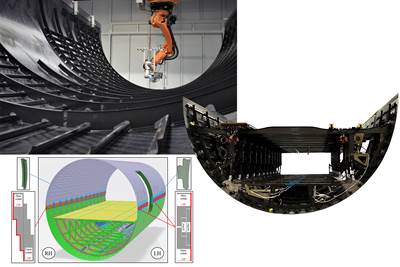

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreJEC World 2023 highlights: Innovative prepregs, bio-resins, automation, business development

CW’s Jeff Sloan checks in with JEC innovations from Solvay, A&P, Nikkiso, Voith, Hexcel, KraussMaffei, FILL, Web Industries, Sicomin, Bakelite Synthetics, Westlake Epoxy and Reliance Industries.

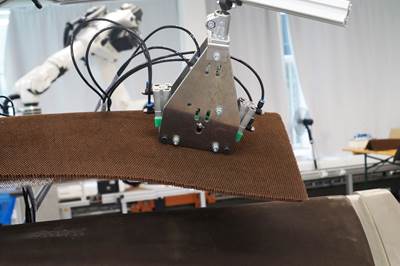

Read MoreACoSaLUS project updates for automated sandwich panel layup

Cevotec and project partners have made significant progress in line with 2023 completion, including improvement of automated handling, patch vision inspection, and the laminate design and patch placement process.

WatchAirbus selects Airborne to supply automated ply placement system

The pick-and-place system with software-driven automated will be the first in Airbus facilities, enabling highly efficient and flexible dry fiber preform manufacture for A350 structures.

WatchAirborne delivers composite upper stage tank for EU ENVOL project

Nine-member consortium targets development of low-cost, green vertical orbital launcher with manufacture of an ultra-lightweight composite tank design in an automated manufacturing environment.

Read MoreFraunhofer IFAM advances automation, robotics development for large composite structures

New developments in automated or semi-automated manufacturing solutions through MFFD, CoMMaNds 2, FastFlexMont 2, Tempo and UniFix projects to achieve sustainable, efficient composite part production.

Read MoreBio-inspired EV underbody panel developed by TPI Composites, Helicoid Industries

Composite underbody panel for battery pack protection, made of stacked multiaxial noncrimp fabric, will serve high-volume commercial and automotive markets.

Read MorePlataine releases updated version of AI-based scheduler program

The latest version of Plataine’s Production Scheduler Solution considers relevant elements when generating optimized manufacturing schedules, including human capacity, tool availability and autoclave optimization.

Read More