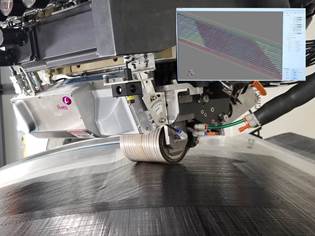

Existing composite inspection solutions rely on 30-year-old sensing technology which has not evolved to meet the stringent requirements of capturing high-quality images of composite surfaces concurrent with the layup process. The impact of using low-fidelity sensing technology degrades the efficacy and return-on-investment of the measurement system. Fives and the National Research Council of Canada have partnered to develop a novel sensing platform tuned from the ground up for the task of collecting the highest quality inspection data without impeding the performance and work envelope of the AFP machine. This technology is truly a game changer.

Primary Topics:

- The key elements of a production, in-process inspection system

- Learn how composites inspection has evolved and what the future looks like

- Application of the inspection data

- Quantify the return of implementing In-Process Inspection

Presenters:

Robert Harper

Technical Sales and Market Development Director, Fives Composites

Robert has worked for Fives for the past 29 years. He has held various positions, including leading manufacturing teams responsible for the assembly of composites processing equipment. He is currently the Director of Technical Sales and Market Development, where he works directly with large aerospace companies and component suppliers.

Gil Lund

Program Manager, Fives Composites

Gil has 26 years' experience in the instrumentation, sensor research and development, data analysis and IIOT/edge compute platform development. He has been with Fives for 15 years, where he is currently the Program Manager focusing on strategic technology capabilities specializing in custom, industrial robotic solutions.

.jpg;maxWidth=300;quality=90)