IDEC uses additive manufacturing to cut composite tooling costs

IDEC explains how Stratasys 3D printing helped the company cut the time, cost and material waste involved with traditional composite molding.

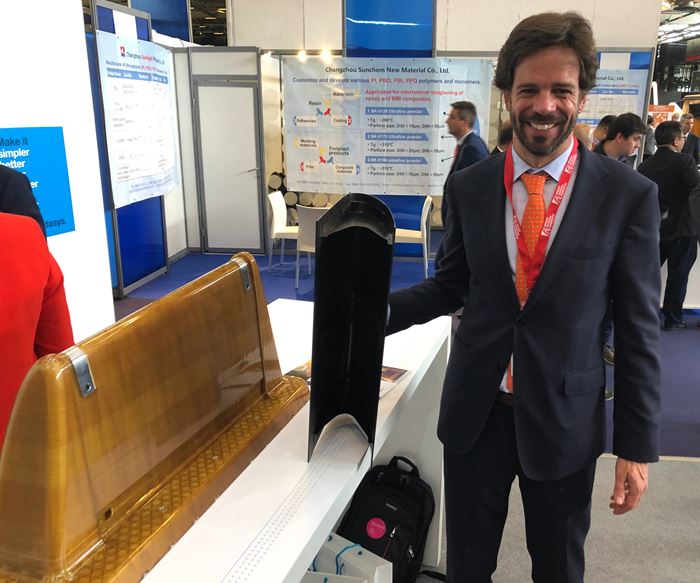

During JEC World 2019, I visited the Stratasys (Rehovot, Israel) booth where Diego Calderón, Structural Analysis manager at IDEC (Araba, Spain), a Spanish provider of composite solutions for aerospace, explained how Stratasys additive manufacturing helped IDEC cut the time, cost and material waste involved with traditional composite molding.

IDEC’s government-funded project centered around the testing of a new composite material and its Resin Transfer Molding (RTM) process for the manufacture of a curved aircraft wing. The particular challenge in producing the aircraft wing centered around the preform tool itself. Designed to facilitate the composite lay-up process into the mold at a later stage and accelerate the curing process, such preform tools are often made of aluminum or epoxy resin. The fiber is laid up on top of the preform and the tool is then heated. In this instance, instead of heating the preform tool, the unusual application required the composite material itself to be heated using an electric current. Consequently, highly conductive metals like aluminum were inappropriate as they would prevent the current from effectively going through the carbon fiber fabric.

IDEC enlisted help from Wehl & Partner (Rottweil, Germany), which manufactured a large scale preform tool using a Stratasys F900 Production system. ULTEM 1010 resin was selected for the tool’s manufacture. The material’s good chemical and heat-resistance enabled it to withstand temperatures exceeding 150° C, as well as high pressures.

“This project required high temperatures of between 150°C and 180°C to heat the fabrics directly, which made Stratasys FDM additive manufacturing and the use of ULTEM 1010 resin, in particular, the perfect choice,” says Calderón. “Although there are epoxy resins resistant to such high temperatures, these are very expensive, and would not have been financially viable.”

Calderón claims the material attributes also simplified the preform production process and provided efficiency savings.

“Stratasys additive manufacturing enabled us to produce the preform tool in just 60 hours. With CNC machining, it would have taken at least four weeks to produce this type of part,” he says. “With ULTEM 1010 resin, we reduced the composite heating stage from one hour to only ten minutes by flowing the electrical current directly through composite fabrics.”

The solution reportedly allowed for a savings of around 67% of the costs of CNC machining using aluminum and produced good mechanical properties. According to Calderón, the preform tool is so solid that the team can use it for at least 25 cycles.

Related Content

-

Composite rebar for future infrastructure

GFRP eliminates risk of corrosion and increases durability fourfold for reinforced concrete that meets future demands as traffic, urbanization and extreme weather increase.

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

-

Sulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

.png;width=70;height=70;mode=crop)