Researchers introduce capillary-driven method for continuous fiber 3D printing

The LITA 3D printing system from the University of Delaware shows potential for in situ cure for high-performance carbon fiber composite parts.

Source | University of Delaware

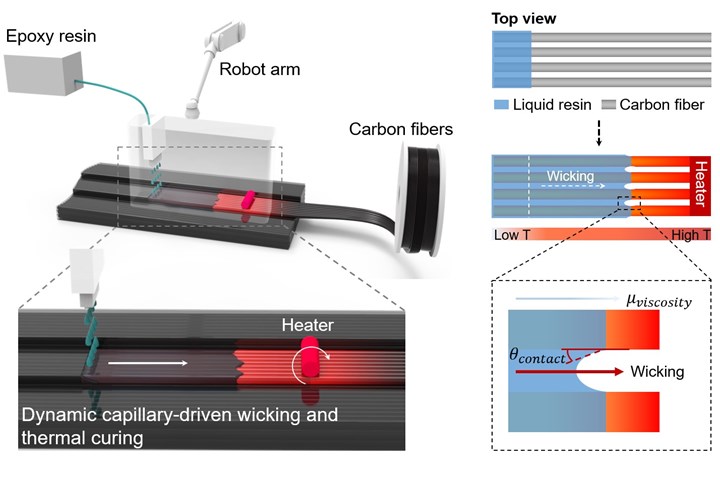

New research in continuous-fiber 3D printing shows potential for additively manufactured composite parts for a range of industries — including space. Published in the academic journal Matter, researchers from the University of Delaware’s (Newark, Del., U.S.) Center for Composite Materials (CCM) recently introduced a lab-scale method for continuous-fiber 3D printing that incorporates robotics and a capillary-based, in situ heat cure system for fast, additively manufactured carbon fiber composite parts using high-temperature thermoset resins.

“We call it one-step 3D printing,” says Dr. Kun Fu, assistant professor at the University of Delaware and an author on the study. Called the localized in-plane thermal assisted (LITA) 3D printing method, the system comprises an all-in-one printhead mounted on a robotic arm that includes carbon fiber dispensed from a spool, a guiding bar, a liquid resin nozzle and an electric heater. As the fiber is placed onto the part surface, liquid resin is sprayed onto the fibers and is immediately followed by the heater, which, Fu explains, both aids in infusion and in curing of the part. Fu adds that the heating process reduces the viscosity of the room-temperature resin, helping it to infuse into the fibers without need of a vacuum along capillaries, or tube-shaped gaps, between the fibers. Depending on the needs and size of the part being manufactured, Fu says, the temperature of the heater can be increased or reduced to control the viscosity of the resin.

The current, lab-scale LITA 3D printing system. Source | University of Delaware

This method reportedly enables nearly simultaneous wetting and curing of continuous fibers with thermoset resins, with potential to quickly producing 3D composite components with complex geometries and the high mechanical properties that come from continuous fibers and high-temperature thermosets. The researchers have also demonstrated the system can be used for horizontal and vertical printing, Fu says, and on planar or curved surfaces, adding to the system’s flexibility.

“The technique has been very promising so far,” Fu says, “and as far as we know, we’re the first to publish a technique like this.” According to Fu, the researchers are in the process of obtaining a patent for the technology.

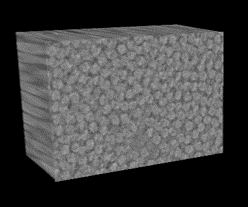

3D CT image of a composite produced with LITA 3D technology. Source | University of Delaware

In addition, the University of Delaware and partner KAI (Dallas, Texas, U.S.) recently received a NASA grant to use the LITA 3D printing method for manufacture of continuous carbon fiber-reinforced composite components for thermal protection systems on NASA spacecraft and lander systems. Fu says that the LITA 3D printing system was chosen for its ability to print with high-temperature resins.

Currently, the technology has only been demonstrated at a small scale – 3K carbon fibers were used for the study – but Fu says the team is working to scale up the robotic system to enable use of wider carbon fiber tows for larger components. The researchers are currently looking for companies interested in collaborating on scale-up and subsequent commercialization of the technology.

To access the Matter article, go to www.sciencedirect.com/science/article/pii/S2590238520301818.

Related Content

Cycling forward with bike frame materials and processes

Fine-tuning of conventional materials and processes characterizes today’s CFRP bicycle frame manufacturing, whether in the large factories of Asia or at reshored facilities in North America and Europe. Thermoplastic resins and automated processes are on the horizon, though likely years away from high-volume production levels.

Read MoreCarbon fiber in pressure vessels for hydrogen

The emerging H2 economy drives tank development for aircraft, ships and gas transport.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreRead Next

From the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read MoreComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read More

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)