Microfiber-infused resin enables single-step molding process

Spoke Materials’ reinforced liquid composites provide alternative fabrication methods.

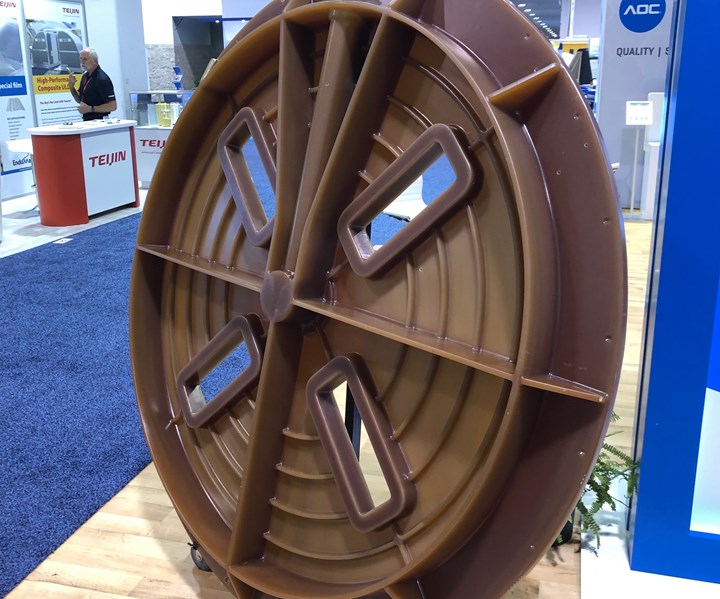

Spoke Materials’ MIR-170 reinforced liquid composite was used to manufacture a composite chemical tank base component that weighed only 180 pounds and replaced a more than 1,000-pound stainless steel part. CW photo | Scott Francis

Spoke Materials Inc. (Indianapolis, Ind., U.S.), a new resin technology company has acquired a line of molding and casting resins, structural adhesives, and pastes and putties originally developed by Mirteq Inc. (Fort Wayne, Ind., U.S.). Spoke is improving and relaunching the advanced composite material to provide alternatives to traditional methods such as RTM, hand layup and infusion that use long fibers. According to Spoke Materials CEO Joe Locke, its MIR line of products can reduce labor, raw materials cost and decrease production time for many detailed parts as the products require no additional reinforcement or expensive tooling.

Spoke’s approach uses AOC Aliancys’ (Collierville, Tenn., U.S.) vinyl ester resins, which are modified using Spoke’s Materials’ patented microfiber infusion process to develop its MIR products. Spoke’s technology first treats glass microfibers with a proprietary process and then infuses the fibers into the vinyl ester resin, which increases strength, impact and abrasion resistance, performance and durability in a single-step/single-pour molding process.

“These products are not ‘replacements’ for long fibers, but are possible alternatives for detailed applications, molded-in features or thick cross-sections where there would be a lot of manual labor or multiple materials in the fabrication process,” explains Locke. “In some cases, this alternative can replace those processes, sometimes cutting costs in half, and in some instances up to 85%.”

In most cases the single-pour approach enabled by MIR products also allows expensive tooling to be replaced by molds made of polyurethane or fiberglass tooling board, offering further cost savings. In addition, the products cure at room temperature, can be machined or milled, and are chemical- and corrosion-resistant.

One example of Spoke’s technology is a composite chemical tank base created to replace a stainless steel part that weighs more than 1,000 pounds. According to Locke, the new MIR-based part weighs only 180 pounds — 82% lighter than the original — and reduces the production time from 4-5 days to just hours. In addition, the composite version is corrosion- and chemical-resistant.

The tank base was fabricated using Spoke Materials’ MIR-170, a material specifically designed for the molding of thick parts and cross-sectional applications. The low-exotherm product allows fabricators to develop complex, detailed parts up to 3 inches thick with a decreased risk of internal cracking.

“A lot of times in those thick cross-sections you’ll get cracking and crazing, or it just doesn’t cure properly,” says Locke. “MIR-170 utilizes Spoke’s ControlCure technology allowing the part to cure evenly.”

The original stainless steel part was not only costly to manufacture, but it was also costly to ship and required heavy machinery to put in place and maintain. The composite version can be installed by one or two workers. In addition, it costs 90% less to fabricate.

According to Locke, the tank component is an example of how Spoke’s technology might enable new applications. For a customer accustomed to building chemical tank parts out of steel, the composite solution opens a new market. In the architectural sector, the material is proving to be a highly effective solution for restoring decaying stone features; such refurbishment, using traditional methods, can take weeks and cause construction delays and higher costs. With Spoke’s solution, the old part can be removed and reassembled to cast a new mold and pour using the MIR material.

While MIR materials aren’t a one-size-fits-all solution, the technology can be a cost- and time-saver in a number of applications. According to Locke, the key to using Spoke Materials’ products lies in understanding the material-application match. “We always try to get into the front end of the application before a customer starts building molds,” says Locke. “It’s important to understand what it works for and make that change up front.”

Related Content

From the CW Archives: Airbus A400M cargo door

The inaugural CW From the Archives revisits Sara Black’s 2007 story on out-of-autoclave infusion used to fabricate the massive composite upper cargo door for the Airbus A400M military airlifter.

Read MoreNovel dry tape for liquid molded composites

MTorres seeks to enable next-gen aircraft and open new markets for composites with low-cost, high-permeability tapes and versatile, high-speed production lines.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreMaterials & Processes: Tooling for composites

Composite parts are formed in molds, also known as tools. Tools can be made from virtually any material. The material type, shape and complexity depend upon the part and length of production run. Here's a short summary of the issues involved in electing and making tools.

Read MoreRead Next

Composites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read More

.png;width=70;height=70;mode=crop)