Making carbon fiber green

Composite Recycling Technology Center is being established in Washington State.

Port Angeles, Washington is no stranger to composites. Situated on the Olympic Peninsula, the area is home to Angeles Composite Technologies, Inc. (9,290 m2), a supplier of carbon-fiber parts for Boeing and Bombardier aircraft and longtime composite yacht builder Westport Yachts’ Port Angeles Shipyard (9,290 m2). Of course, Port Angeles is 2.5 hours northwest of Seattle and directly west of Everett, home to production of the Boeing 787 Dreamliner, featuring all-composite fuselage and wings, and also the upcoming 777x which boasts the longest composite wings to date.

Having recently written an article on carbon fiber recycling, and understanding both the great need and potential for composites’ future, I was surprised to see a recent press release that described the CRTC’s steps to outfit its 2,323 m2 facility, in preparation for relocating and housing Peninsula College and spinning up operations. I hadn’t even heard of the CRTC.

Jennifer States is the Business Development Director for the Port of Port Angeles, the entity which owns the CRTC property and is supporting its vision and development. “Of course this began as an economic development initiative,” States explains, “but now we see an ever larger part we can play in the advancement of composites manufacturing by making it more environmentally friendly and sustainable.” States explains that the Port of Port Angeles had been working to pull together a composites consortium to pursue R&D opportunities. “In all of the conversations we had with our industry partners, recycling kept coming back as a huge need,” says States. The composites consortium that included the Port of Port Angeles applied for a grant from the US Dept. of Energy’s Advanced Technologies for Clean Energy Manufacturing program. Although they did not win that, industry interest in establishing the CRTC and the overall viability of the approach resulted in the Port of Port Angeles proceeding with development, including pursuit of new funding opportunities.

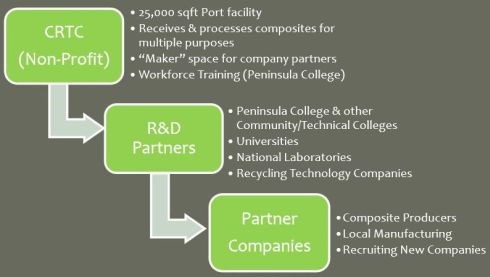

The Composites Recycling Technology Center will initially focus on gathering scrap carbon fiber prepreg materials and process them for reuse. SOURCE: CRTC.

States explains that the initial focus is recycling uncured prepreg materials. According to the Washington State Dept. of Ecology, over 900,000 kg of carbon fiber scrap is landfilled annually. She describes, “We’re looking at gathering that material and processing it to make it reusable. Our initial plans are to have refrigerated trucks at our partners’ manufacturing sites where they can deposit the scrap prepreg.” This will minimize prepreg outtime and help to preserve its material properties. She continues, “We will bring the trucks here, sort and then process the material. One form will be strips which can be molded into new products. We are also looking at what can be automated and how to increase the efficiency of the sorting and processing operations.”

Eventually, the CRTC will consider glass fiber prepreg as well as cured material scrap. However, States says the CRTC’s vision is not to compete with the companies currently recycling carbon fiber scrap, such as MIT-RCF (Lake City, SC, US), “but we see synergies with them.” She explains, “We are discussing how to work together and possible R&D projects that could strengthen and expand market pull for recovered products, for example increased fiber alignment.” This is also part of the vision for the center, to pursue R&D demonstrating how to use recycled materials so that companies are more able to take advantage and the industry overall can “close the loop”.

The Composite Recycling Technology Center vision encompasses workforce training and industry education, improving composites’ environmental impact and sustainability and R&D to support composite manufacturing and recycling companies. SOURCE: CRTC.

States details the CRTC’s three mission areas:

- Environment — reduce the amount of composite manufacturing waste being landfilled in Washington State, and eventually, nationwide.

- Economic Development — add jobs and attract new companies to Washington State and the Olympic Peninsula, but also help to make composite manufacturing business more profitable.

- Education — aid in developing a workforce trained in composite reclamation, recycling and reuse, but also support and perform R&D to keep expanding composites recycling by improving processes and recycled products.

She details, “This will be a multi-use facility, with a full suite of services offered. For example, companies can contract with us to show them how to use recycled materials or they can simply use the equipment here. There will also be incubator space and acreage is available to build out as well as buildings already designed that companies could move into.” In fact, there are hundreds of industrial-zoned acres available at the adjacent Port Angeles Airport and another 2,323 m2 building pad ready for future CRTC expansion.

The CRTC will also house Peninsula College, which is moving into the CRTC facility and partnering in workforce development. “They already have a class on composite recycling,” States notes, “and are looking to build a full certification program.”

“The majority of our partners are from the aerospace industry,” says States, “but we are in discussions with manufacturing operations for other end-use applications as well. The recycled carbon fiber materials will not go back into aerospace end uses but could go into recreational products and perhaps even marine applications. We have a couple of companies from these industries already interested in the recycled products and we are exploring how they could use them.”

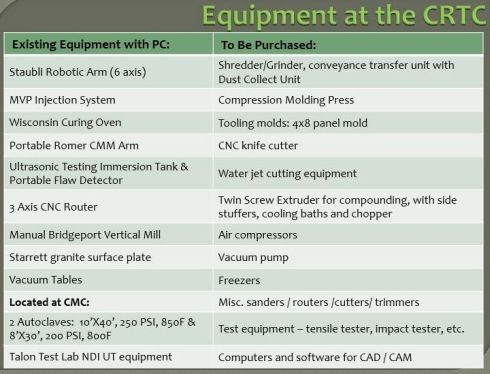

For now, States is headed to the 2015 JEC show (Mar 10-12, Paris, France), with an equipment shopping list (see below) and planned discussions with potential additional industry partners. You can find them at the Washington State Department of Commerce booth, 7.3 M63 in the US Pavilion.

Related Content

Women in the Composites Industry brings together women for networking, educational opportunities

Aiming to support the growth of women in this industry, the WCI industry group and its partners recently held its first live training event hosted by Owens Corning.

Read MoreUniversity of Sheffield researchers to drive structural health monitoring in U.K. infrastructure

The £7.7 million program, ROSEHIPS, anticipates exploitation of machine learning, sensing and digital twin technology for automated health monitoring in infrastructure, such as bridges, telecoms masts and wind turbines.

Read MoreMaterials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

Read MoreUniversity of Maine unveils 100% bio-based 3D-printed home

BioHome3D, made of wood fibers and bioresins and entirely 3D printed, highlights Maine’s effort to address the need for more affordable housing.

Read MoreRead Next

From the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read MoreComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read More