JEC World 2019: Boston Materials

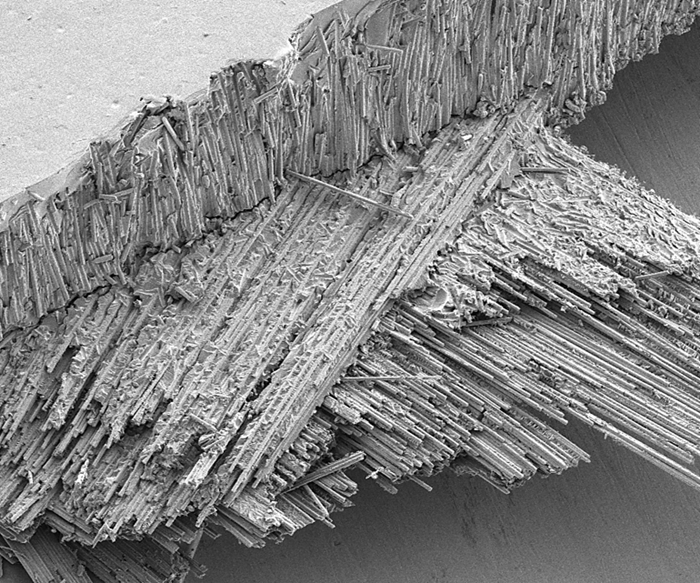

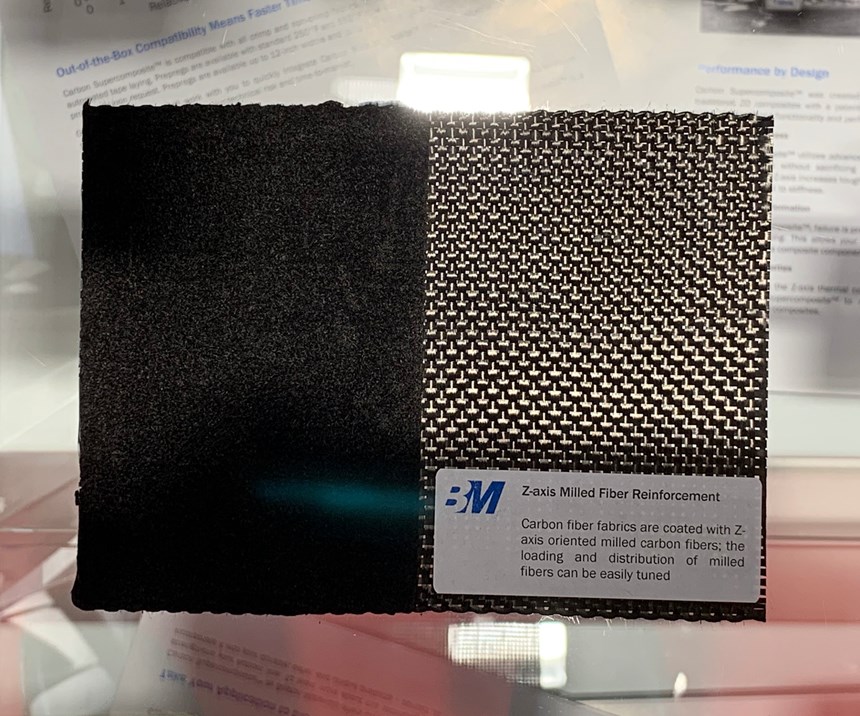

Boston Materials announced its Carbon Supercomposite, a carbon fiber fabric that features milled carbon fibers magnetically aligned in the “z” direction to provide uncommon ply-to-ply strength.

Boston Materials (Bedford, Mass., U.S.) announced at JEC World 2019 the development of its Carbon Supercomposite, a carbon fiber fabric that features milled carbon fibers magnetically aligned in the “z” direction to provide uncommon ply-to-ply strength. Although Boston Materials is working with Sabic (Pittsfield, Mass., U.S.) to integrate Carbon Supercomposite with polyetherimide (PEI) and polycarbonate (PC), the fabric, says the company, is resin agnostic and compatible with any thermoset or thermoplastic resin matrix. Anvesh Gurijala, founder and CEO of Boston Materials, says Carbon Supercomposite can increase compressive toughness by as much as 300 percent and compressive strength by 35 percent compared to traditional prepreg systems. He said the company is initially targeting sporting goods and overmolding applications, but the material clearly has potential in a variety of end markets.

Related Content

-

One-piece, one-shot, 17-meter wing spar for high-rate aircraft manufacture

GKN Aerospace has spent the last five years developing materials strategies and resin transfer molding (RTM) for an aircraft trailing edge wing spar for the Airbus Wing of Tomorrow program.

-

Cycling forward with bike frame materials and processes

Fine-tuning of conventional materials and processes characterizes today’s CFRP bicycle frame manufacturing, whether in the large factories of Asia or at reshored facilities in North America and Europe. Thermoplastic resins and automated processes are on the horizon, though likely years away from high-volume production levels.

-

Novel dry tape for liquid molded composites

MTorres seeks to enable next-gen aircraft and open new markets for composites with low-cost, high-permeability tapes and versatile, high-speed production lines.