Index activity expands, led by production

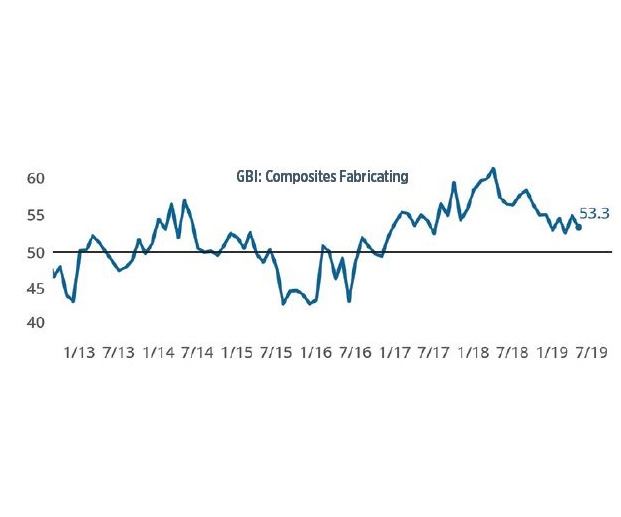

The Composites Fabricating Index for May 2019 came in at 53.3, led higher by production activity.

The Composites Index closed May at 53.3, extending its ongoing record of consecutive months of expanding industry activity. The latest Index reading is 7.6% lower compared to the same month one year ago, indicating slowing growth within the industry over the past year. In the year-to-date period the Index has averaged 53.8, indicating consistent but modest business activity expansion. Index readings above 50 indicate expanding business activity, while a value of 50 indicates no change and a reading below 50 indicates contracting business activity. Gardner Intelligence’s review of the underlying data indicates that the Index was propelled by production which was followed by employment, new orders and supplier deliveries. The Index — calculated as an average — was pulled lower by backlogs and exports; both contracted during the month.

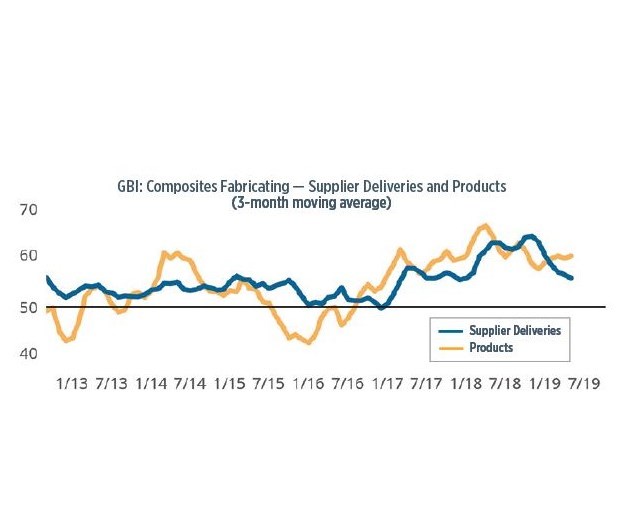

May’s supplier delivery data was notable for expanding more slowly than new orders, production and employment. The last time this occurred was late 2017, shortly before a record-setting surge in new orders activity in early 2018 that caused supply chains to scramble in reaction to meet demand. The latest data may suggest that upstream suppliers have largely restocked those formerly depleted inventories.

More information about the Composites Fabricating Index can be found at http://www.gardnerintelligence.com/.

Related Content

-

Novel composite technology replaces welded joints in tubular structures

The Tree Composites TC-joint replaces traditional welding in jacket foundations for offshore wind turbine generator applications, advancing the world’s quest for fast, sustainable energy deployment.

-

JEC World 2022, Part 1: Highlights in sustainable, digital, industrialized composites

JEC World 2022 offered numerous new developments in composites materials, processes and applications, according to CW senior editor, Ginger Gardiner, most targeting improved sustainability for wider applications.

-

Materials & Processes: Fibers for composites

The structural properties of composite materials are derived primarily from the fiber reinforcement. Fiber types, their manufacture, their uses and the end-market applications in which they find most use are described.

.jpg;width=70;height=70;mode=crop)