Earlier this year, the first installment of eighth-generation Chevrolet Corvette sports cars (C8s) from General Motors Co. (GM, Detroit, Mich., U.S.) came rolling off GM’s Bowling Green, Ky., U.S. assembly line. Described as the “fastest, most powerful entry Corvette” in the model’s 67-year history, it’s also the most composites-intensive Corvette, and the first to feature a mid-engine configuration. Not only is the 2020 Corvette Stingray beautiful and fast, but it’s tricked out with a host of luxury features. However, don’t let good looks and fast track times fool you: there’s plenty of composites innovation on this car. CW’s two-part coverage of composites use in this vehicle began in the July 2020 issue. This is part 2.

Body structure: part B

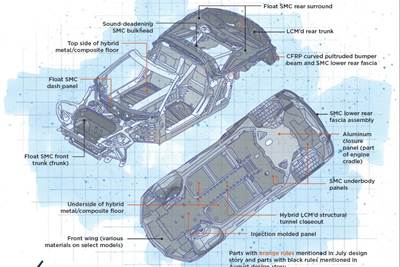

The new Corvette features not one but two trunks that, combined, hold 12.6 cubic-feet/0.36 cubic meters of cargo. Both trunks are produced in 42 wt-% chopped fiberglass/vinyl ester-unsaturated polyester (VE-UP) resin, but use different processes driven by geometry and mechanical requirements. The front trunk (frunk) is compression molded 0.95-specific gravity (SG) “float” sheet molding compound (SMC), while the rear trunk is formed via the proprietary PRiME (Prepositioned Reinforcement ensuring Manufacturing Excellence) process, a liquid compression molding (LCM) variant. The float SMC and the PRiME process were developed by processor Molded Fiber Glass Co. (MFG, Ashtabula, Ohio, U.S.). MFG produced all structural SMC and LCM’d parts on the car.

“Although both spaces are characterized by shallow-draft, long-draw walls, the frunk is smaller than the rear trunk, and could be compression molded,” explains Chris Basela, Corvette body structure lead engineer. “The rear trunk needed higher mechanical performance and was a tough geometry to fill with an SMC charge. Because the PRiME process lets us change fiber length, we could use longer pre-positioned reinforcement in our preform. Flowing the resin [not the glass] proved the best approach.”

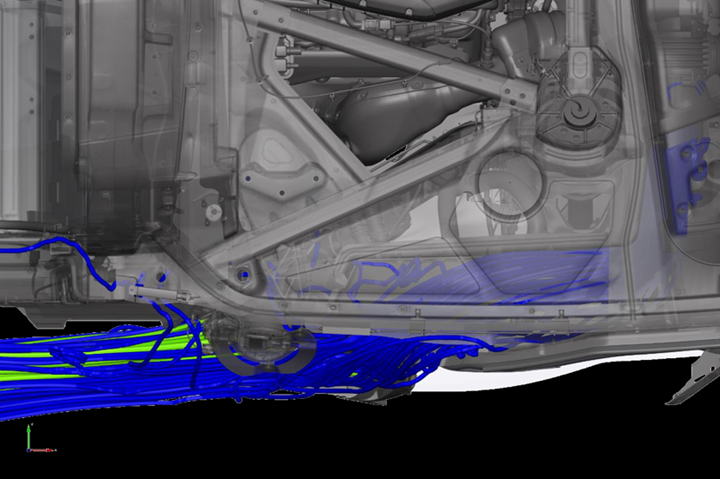

The 2020 Corvette is the first car to use body-structure cavities (integral to the body frame) for air-induction ductwork (above), which is fed by multiple primary cooling paths (below). The car’s naturally aspirated V8 engine needs a lot of air, so it was important to ensure good, unimpeded airflow to keep the engine cool. Source (both images) | General Motors Co.

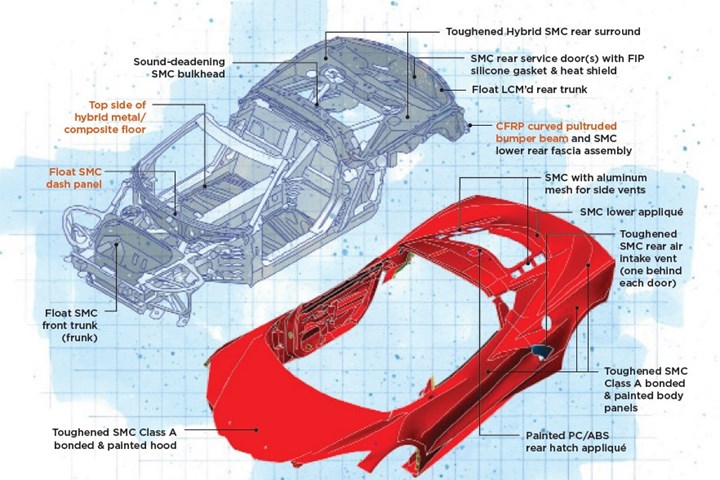

Clever engineering and a new material were key to cooling the C8’s engine. Multiple primary cooling paths (rear inlets behind each door, front wheelhouse vents, and outboard cooling inlets) feed highly complex induction ducts that funnel air through the vehicle and across the engine, before ejection through aluminum-mesh vents and SMC appliqués on either side of the glass partition that showcases the Corvette engine. The appliqués are made with MFG’s float (0.95-SG) SMC (chopped glass/UP-VE resin). Low in volatile-organic compounds (VOCs), the material reduces emissions and eliminates the need for resonators on rear-induction ducts, while reducing cost and mass (2.4 kilograms) versus alternative technologies.

The massive, customer-visible rear surround frame — 64 by 69 by 24 inches (163 by 175 by 61 centimeters) — that surrounds the rear-half of the passenger compartment is compression molded in toughened 1.2-SG SMC. This hybrid-reinforced material features carbon fiber at 15% fiber-volume fraction (FVF) and glass fiber at 30% FVF, with a low-VOC UP resin, formulated to withstand engine-bay heat. The frame forms the dimensional foundation for all rear exterior and interior panels, yet flexible design enables it to be used for multiple model variants. Thanks to significant parts consolidation, secondary attachments were eliminated, increasing interior package space, reducing noise/vibration/harshness (NVH), providing better body structure and sealing performance, improving rear-hatch visibility and reducing mass (15%) and cost versus the outgoing frame. “Given the size of this part, which is almost 6 by 6 feet tall and 2 feet deep, we actually had to make the material flow uphill in the mold, so we were all a little worried on that first shot,” Basela recalls.

The very-large, customer-visible rear surround frame provides the dimensional foundation for all rear exterior and interior panels. Each half of the mold in which the part is formed weighs ~35,000 pounds/15,900 kilograms and was produced by Century Tool, a division of Tooling Tech Group (Fenton, Mich., U.S.). The compression press itself has 2,800 tonnes clamping pressure and a platen that measures 108 by 68 inches (274 by 173 centimeters). Despite its size, cycle time is a nominal 3 minutes. | SPE Automotive Div.

Equally interesting is the bulkhead (mid-window frame), which was custom-formulated by MFG to resolve high heat and noise challenges, since this portion of the cabin sits directly over the V8 engine. Fiberglass reinforcement combined with beryllium graphite filler in low-VOC VE-UP resin deadens sound transmission into the passenger compartment so effectively that it eliminated the need for secondary sound-deadening countermeasures. That, in turn, reduced costs, increased interior package space and passenger comfort, and improved body sealing and NVH. “With a specific gravity of 2.2, this is the first composite part I’ve ever been asked to add mass to rather than take it out,” laughs Basela.

Closures and trim

Exterior body panels are all bonded (inner/outer), painted, toughened 1.2-SG SMC (22-28% FVF fiberglass/UP resin, depending on component) from Continental Structural Plastics (CSP), a Teijin Group company (Auburn Hills, Mich., U.S.). By bolting on composite closures, GM achieves the C8’s aggressive styling, aerodynamics and functional cooling integration, with cost-effective lightweighting on multiple model variants using common parts. All body panels are painted inline on a “skuk system” in vehicle position, using Bowling Green’s innovative robotic wet-sanding process.

Rear service doors are molded from toughened SMC and feature a high-temperature, foam-in-place silicone gasket that provides a durable seal with excellent compression-set resistance while handling long-term exposure to engine-bay heat. Another composite — heat- and abrasion-resistant aluminized aramid fabric — is used as a heat shield to provide extra thermal protection on door interiors. | SPE Automotive Div.

Another innovation involves use of a one-part, thixotropic silicone elastomeric foam gasket applied to the back side of SMC service doors, which are located in the rear trunk (one on coupés, two on convertibles), and permit customer access to the air-filter system. Owing to proximity to the engine bay, the high-performance foam-in-place (FIP) elastomer (Silastic 3-8186 from Dow, Inc., Midland, Mich., U.S.) was specified to survive continuous-use temperatures up to 392°F/200°C while providing a durable seal with excellent compression-set resistance, even after repeated open/close cycles. GM reports that most other die-cut foams and gaskets would either have melted or broken down under continuous exposure to such temperatures. After dispensing, the applied gasket is heat-treated at 167°F/75°C for 10 minutes to expand the foam, eliminating die-cutting cost and waste. The doors themselves are toughened SMC (42% FVF glass in a VE-UP matrix). Heat shields, produced by Gentex Corp. (Carbondale, Pa., U.S.) using heat- and abrasion-resistant aluminized Kevlar aramid fabrics (fiber from DuPont de Nemours, Inc., Wilmington, Del., U.S.), provide door interiors with extra thermal protection.

The new mid-engine 2020 Chevrolet Corvette Stingray from General Motors Co. is said to be the fastest, most powerful entry-level Corvette in the model’s 67-year history. It’s also the most composites-intensive, with a host of innovative technology. | General Motors Co.

GM also used its second-generation, fully automated precision wheel-balance system on the C8. Developed with The 3M Co. (St. Paul, Minn., U.S.) and ESYS Automation (Auburn Hills, Mich., U.S.), the high-density (5.8-SG) composite wheel weights with tailored magnetic properties replaced traditional stamped metallic weights in painted steel, zinc or lead that have specific mass and must be hand-applied to wheels. The new system uses large spools of extruded tape with adhesive backing that contain 67% by volume post-industrial, corrosion-resistant, fully recyclable steel alloy in a fluoropolymer base. The automated system examines each wheel, then cuts and applies custom-weight tape segments in smaller, more precise increments to improve ride and reduce tire wear. It also reduces assembly time and cost, simplifies inventory, eliminates scrap and labor and is offered in more colors than metal weights.

Coupé roofs are available in three trim levels: painted, low-density toughened SMC (from CSP); clear, hard-coated polycarbonate (PC); and clear-coated/exposed-weave carbon fiber composite with painted edges (from deBotech Inc., Mooresville, N.C.). CSP also supplies several Class A, toughened 1.2-SG SMC panels for convertible-model retractable-roof systems.

Additional Corvette beauty shots. Source | General Motors Co.

Other exterior trim panels include painted thermoplastic polyolefin (TPO) front fascia upper and lower, the latter with integrated ducts to direct air to brakes (Z51 package only) and outboard heat exchangers. Outer grille and brake cooling vents are painted acrylonitrile butadiene styrene (ABS).

The upper rear fascia is molded-in-color (MIC) TPO, but the lower rear fascia assembly is Class A painted, 1.2-SG SMC (glass/UP resin), owing to the part’s close proximity to hot exhaust tips. SMC’s excellent mechanical performance enabled GM to design an unsupported short rear overhang and use larger spacings between attachments without sagging. SMC also spreads loads efficiently over a larger area during low-speed rear crashes than thermoplastics. Brackets and rear parking-assist sensors are bonded to the SMC. This is said to be the first time SMC bumper fascias have been used on high-volume vehicles.

Rear-hatch appliqués feature painted PC/ABS for the upper panel, SMC with aluminum mesh for side vents and an SMC lower appliqué to accommodate thermal loading directly over the engine. These SMC panels are produced by LyondellBasell’s Quantum Composites Inc. (Bay City, Mich., U.S.). Door-handle release switches are PC/ABS, while the rear air-intake vent is SMC. The base car sports a blowmolded, painted ABS spoiler and the rear air-exit grille is injection molded painted ABS. A-pillar and header appliqués are painted ABS, as are exterior side-view mirror caps and radiator inlet grilles. Depending on the option package, a toughened SMC front underwing and either a blowmolded TPO or carbon fiber composite front splitter/diffuser — clear-coated/visible-weave carbon/epoxy produced by deBotech using prepreg from Solvay Composite Materials (Alpharetta, Ga., U.S.) — contribute additional aerodynamic stability. A rear diffuser in toughened SMC mates to the SMC lower rear fascia in Class A painted SMC from MFG.

The premium carbon fiber trim package features various clear-coated/visible weave carbon fiber accents inside and out, including mirror caps, front grille insert, front splitter, accessory wing, engine-compartment covers, interior door switch plates, rocker moldings, instrument-panel cluster bezel, door-handle covers, quarter appliqués and ride-control plate. These components are produced by deBotech, SMI Composites LLC (Comer, Ga., U.S.) and Plasan Carbon Composites (Wixom, Mich., U.S.).

The Corvette is not only fast and beautiful but contains a host of creature comforts. For composites aficionados, the premium carbon-trim upgrade adds numerous clear-coated/visible-weave carbon fiber composite accents to exterior and interior surfaces, such as the ride-control plate shown here. | General Motors Co.

Advancing technology

The 2020 Corvette has already won many prestigious industry awards, including 2020 MotorTrend Car of the Year, 2020 Automotive News PACE (Premier Automotive supplier Contributions to Excellence) Partnership Award, and several awards from the Society of Plastics Engineers (SPE), including 2019 Vehicle Engineering Team Award. “Although the new Stingray’s mid-engine architecture has dominated headlines, no matter where the engine is — in front of or behind the driver — for eight generations, Corvettes have always advanced the state of the art in automotive materials technology,” adds Tadge Juechter, executive chief engineer-Global Corvette. “Advancing technology is at the heart of what we do.”

Related Content

The state of recycled carbon fiber

As the need for carbon fiber rises, can recycling fill the gap?

Read MorePrice, performance, protection: EV battery enclosures, Part 1

Composite technologies are growing in use as suppliers continue efforts to meet more demanding requirements for EV battery enclosures.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreCarbon fiber in pressure vessels for hydrogen

The emerging H2 economy drives tank development for aircraft, ships and gas transport.

Read MoreRead Next

Composites-intensive masterwork: 2020 Corvette, Part 1

Eighth-generation vehicle sports more composites, and features parts produced using unique materials and processes.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read More