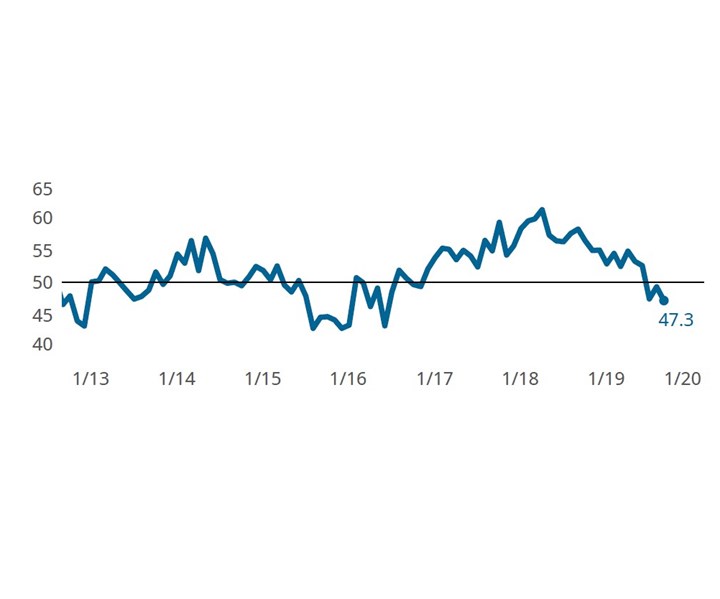

Composites Index contracts for third month

The Composites Index experienced its third month of contracting activity in September, registering 47.3.

Business activity contracts on new orders and backlogs. A quickening contraction in business activity sent the Composites Index lower in September. A broadening contraction in backlogs and new orders more than offset gains from supplier delivery activity.

The Composites Index experienced its third month of contracting activity in September, registering 47.3. Index readings above 50 indicate expanding activity, while values below 50 indicate contracting activity. The further away a reading is from 50 the greater the change in activity. Gardner Intelligence’s review of the underlying data found that the gauge for supplier deliveries was the only expanding component within the Index. Both new orders and backlog activity readings fell sharply to levels last experienced in mid-2016. The remaining components of the Index all registered mildly contracting activity levels.

For a second month, the export reading registered higher than new orders; however, because September’s figures were both contractionary — with total new orders reading four points lower — the implication is that both domestic and foreign orders for manufactured composites goods contracted.

The spread between production and new orders activity narrowed in September after significantly widening in the prior month; overall this appears to have done little to support backlog activity, which fell to a multi-year low. In two of the last three months, production activity has contracted while supplier deliveries have experienced stable expansion, a trend that seems destined to change.

More information about the Composites Fabricating Index can be found at http://www.gardnerintelligence.com/

Related Content

-

Plant tour: Arris Composites, Berkeley, Calif., U.S.

The creator of Additive Molding is leveraging automation and thermoplastics to provide high-volume, high-quality, sustainable composites manufacturing services.

-

Materials & Processes: Fibers for composites

The structural properties of composite materials are derived primarily from the fiber reinforcement. Fiber types, their manufacture, their uses and the end-market applications in which they find most use are described.

-

Two-time F1 champion Fernando Alonso, SimplyEV debut Kimoa e-bike at Miami Grand Prix

The Formula One driver’s sustainable mobility Kimoa brand is debuting its fully customizable carbon fiber e-bike powered by 3D printing firm Arevo.

.jpg;width=70;height=70;mode=crop)