A look at Essentium’s plant floor in Texas.

There’s something about companies who get their start with friends gathered around a kitchen table. For industrial 3D printing provider Essentium, this talk was in 2013.

“We were trying to figure out, ‘Okay, are we going to do this startup thing?’ says Blake Teipel, CEO and co-founder of Essentium. “It was one of those moments where the four of us kind of looked at each other and said, ‘We're going to do this. We're going to try to secure investment. We're going to try to launch a company. We believe we have the ability to add value to the marketplace.’”

Seven years later, Essentium is an innovator in both materials and production platforms. The company is disrupting traditional manufacturing processes by bringing strength and speed together, at scale, with a no-compromise material.

With about 100 employees, the company is based in Pflugerville, Texas, and has locations in Waco, Texas; Irvine, Calif.; Singapore and Western Europe.

The company seeks to move industry forward by addressing additive manufacturing at scale with a supply-chain focus on the machine, materials and process. The company works with customers across many sectors, including automotive, aerospace, biomedical, footwear and electronics.

“There's a lot of activity now in manufacturing, but it’s our belief that you need a cohesive material strategy in order to have a breakthrough in additive manufacturing,” Teipel states. “And so that's one of the things that we think distinguishes us from some of the other companies in this space.”

Materials-Focused

Teipel was exposed to additive manufacturing when he worked in design roles at companies such as John Deere and Caterpillar. He was struck with the technology but saw the limitations in being able to produce only certain types of parts. “I was aware of the fact that additive had always had limitations, primarily in materials, in order to make functional, structural and useful parts,” he recalls.

“There's a lot of activity now in manufacturing but you need a cohesive material strategy in order to have a breakthrough in additive manufacturing,”

About a year after launching Essentium, Teipel met Brandon Sweeney, who comes from an additive-manufacturing and extensive materials background. While working at the Army Research Labs, he was part of the group printing parts for drones and quadcopters. While they were able to create great designs, the parts themselves would break before they could be used in actual applications—again showing the limitations of the technology and materials offerings.

So Sweeney headed off to graduate school to focus on materials-related research by applying what he had learned in working with nanomaterial systems to the challenges that he observed in 3D printing. His goal was to make those two worlds collide.

“Long story short, we came up with a way to coat 3D printer filaments with an ink containing carbon nanotubes, and then we microwaved the parts. We learned that we can basically heal and weld the interface through the parts together to make them much stronger than you could otherwise,” Sweeney states. “And then, flash forward, I met Blake and ended up working at Essentium.”

Essentium develops high-performance materials to meet the rigors of the factory floor.

At the beginning of 2019, Essentium raised $22.2 million in funding from investors led by BASF Venture Capital with participation from Materialise, Genesis Park and others. Essentium and BASF extended their strategic partnership to establish a consistent global materials supply chain supportive of Essentium’s High Speed Extrusion (HSE) 3D printing platform.

Essentium continues to introduce new materials to the market—such as PEEK, high-temperature nylon (HTN), HTN-CF25 (25% carbon fiber), and HTN-Z (ESD safe)—designed to deliver high heat, chemical and fatigue resistance and high strength for industrial applications.

Most recently, Essentium worked with Magigoo, a provider of 3D printing bed-adhesive solutions, to improve the bed-adhesion of different engineering-grade polymers, providing manufacturers with a reliable adhesion solution for industrial-scale 3D printing. The Essentium/Magigoo bed adhesives are designed to work with heated beds. The adhesives stick the print firmly in place while printing and then release the print once the bed has cooled. This allows for consistent and reliable printing.

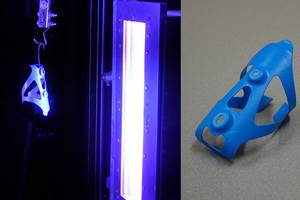

FlashFuse Filament Technology

The company’s patented FlashFuse technology, which draws on Sweeney’s research as a graduate student, utilizes a plasma heat source to conduct electricity through a network of carbon nanotubes integrated into Essentium’s Ultrafuse materials, a new family of filaments created in collaboration with BASF. This reaction in turn welds each layer as it is deposited, thus creating a stronger bond that reportedly achieves the tensile strength of injection molded thermoplastics.

“We want reliability, we want repeatability— that's number one here. We’re not just going to throw it out there in the wild and see what happens.”

“Essentially, what we're doing with FlashFuse is recreating the conditions that are typically seen in that exact same process in injection molding where the flow fronts meet each other and they need to weld to create a full-strength part that gets you back to repeatability,” Sweeney said.

The FlashFuse technology is not yet commercial. “We want reliability, we want repeatability— that's number one here. We’re not just going to throw it out there in the wild and see what happens. Because the goal here is to make customers successful. We want them to produce and use parts that are actually working in the field. And that takes time and attention to do it right. We’ve seen great progress on this and continue to expand the materials offerings that we have that is compatible with the technology,” Sweeney said.

“It's really been fun to see how those core ideas of creating multi-layer filaments has filled out the rest of our materials portfolio,” Sweeney notes. “And, you know, having the opportunity to work on machine-level hardware really forced us to take a hard look at the reliability and the dependability required for an industrial 3D printing platform.”

Machinery ‘Hybrid’

Essentium’s HSE platform is a 3D printing system that reportedly prints parts five to 15 times faster than conventional Fused Filament Fabrication (FFF) printers by utilizing a non-slip, high-torque extruder system and all linear motors.

“I would say this is the perfect hybrid in between a CNC mill and an injection molding machine,” says Sweeney. “It’s designed to stand next to both of those two platforms and make them more productive. It can sit on the factory floor and be very tough and durable.”

Essentium High Speed Extrusion (HSE) 3D Printing Platform in action.

The company has several different models of the machine, from lower- temperature platforms that can handle more generic materials up to a very high-performance, high-temperature machine that can handle aerospace materials and PEEK. The HSE 180 S 3D Printer uses an all-linear servo motor X-Y stage, 3G acceleration, and 1 m/sec deposition speed.

“We designed it with our functional materials in mind,” Sweeney explains. “So the components that feed the material, and everything that is in contact with the filament pathway, are designed to work with industry-standard materials for injection molding, like glass-filled compounds and abrasive materials that have other fillers in them.”

Another key component of the machine is Essentium’s proprietary nozzle. “It has a sapphire tip so that it can withstand thousands of hours, hundreds of kilograms of material running through it with materials that would normally just eat away and destroy most other FFF platforms after just a few hours of printing,” Sweeney notes. “Our system doesn't even blink at those kind of materials.”

“So that gives designers who are used to working with these compounds for injection molding and machining—they can use the exact same materials that they're used to working with on our platform without having to worry about high reoccurring costs associated with wearing out components,” he said. “And overall, our system unlocks speed and scale and strength on the production floor.”

Partner Story

Essentium partners with Vorum to deliver 3D printing for the orthotic and prosthetic market.

Over 30 years ago, Vorum of Vancouver, BC, became the first company dedicated to development of CAD/CAM solutions for design and fabrication of custom orthotic and prosthetic (O&P) devices.

Chris Handford, product manager for Vorum, said that up until the last few years, 3D printing technology hadn’t been relevant to its needs, as it was too slow and costly and the materials were not appropriate for what a patient would wear. As the technology has matured by leaps and bounds in the past five years, it is at a point where 3D printing could be applied in the clinical environment. A big draw is the ability for customization.

Angela Saunders, chief sales and marketing officer for Vorum, said her company connected with Essentium at a trade show. Vorum was impressed with both the printer hardware and the materials they had designed for it. The two companies formed a partnership that will deliver “Essentium + Vorum,” a 3D print solution for O&P customers worldwide. This brings together the Essentium High-Speed Extrusion (HSE) 3D printing platform and materials with Vorum’s O&P CAD/CAM solutions and SurePath methodology. This program is designed to help O&P practitioners make a swift and successful transition from plaster-casting methods to 3D printing in any O&P production setting. The partnership provides O&P clinicians with a complete 3D printing solution for their clinics and practices.

“With the printer we are able to achieve what we need,” Handford states. “In the past, materials had been a challenge and that’s something we have made great progress on due to to what Essentium is providing.”

Related Content

Cycling forward with bike frame materials and processes

Fine-tuning of conventional materials and processes characterizes today’s CFRP bicycle frame manufacturing, whether in the large factories of Asia or at reshored facilities in North America and Europe. Thermoplastic resins and automated processes are on the horizon, though likely years away from high-volume production levels.

Read MoreDigital Demo: UV-Cured Powder Coating on Carbon Fiber

Keyland Polymer's R&D chemist will demonstrate the UV powder coating application process followed by UV curing on a carbon fiber water bottle holder. (Sponsored)

Read MoreMaterials & Processes: Fibers for composites

The structural properties of composite materials are derived primarily from the fiber reinforcement. Fiber types, their manufacture, their uses and the end-market applications in which they find most use are described.

Read MoreRunning shoe insoles get a lift with thermoplastic fiberglass tapes

FlexSpring insoles take advantage of unidirectional, continuous fiberglass and thermoplastics to enable next-level performance for the everyday runner.

Read MoreRead Next

Essentium and Lehvoss Partner to Develop Materials for Additive Manufacturing

Designed specifically for industrial-scale 3D printing.

Read MoreVideo: Essentium and Sulzer Discuss 3D Printed Face Mask Project

In this video interview, Blake Mosher of Essentium and Darayus Pardivala of Sulzer talk about Essentium’s work in creating 3D printed face masks for Sulzer employees.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read More