Automated Preforming, Part 6: Coriolis Composites

Pioneer in automated fiber placement (AFP) advances preforms for overmolded thermoplastic composites enabling production of one automotive part every 20 seconds.

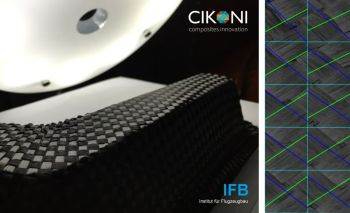

Coriolis Composites automated fiber preforming (AFP) system making preforms for themoplastic composites stamping process at Cetim (Nantes, France) composites lab. Photo Credit all images: Coriolis Composites

Coriolis Composites (Quéven, France) develops robotic systems for automated fiber placement (AFP) using low-cost, high-accuracy six-axis robots for high throughput. Founded in 2001 by three engineers—Yvan Hardy, Alexandre Hamlyn and Clémentine Gallet, who remain at the helm—its engineering expertise continues.

Having demonstrated its first prototype for the German Aerospace Center (DLR) in 1996, the company has over 20 years of experience in the machines, materials and process development used to create finished composite structures and preforms.

Coriolis Composites actually began with industrial and automotive applications, and only later progressed into aerospace. More than 50 machines are installed worldwide, with 25 in rate production of commercial aircraft and others being used in automotive parts development. Coriolis Composites systems offer robust processing, including placement of:

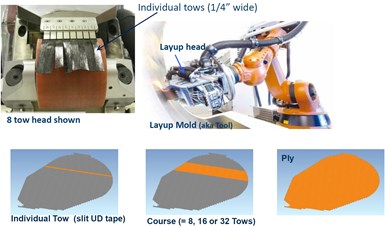

- Continuous and discontinuous fibers.

- Dry fiber, thermoplastic (TP) and thermoset materials at same speed.

- A single tape up to 32 tapes simultaneously.

- 2D (rotary table), 2.5D and complex 3D shapes.

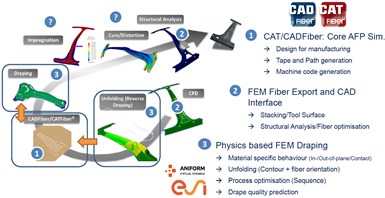

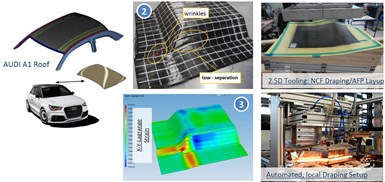

The company has also developed its own suite of software, enabling a fully digital, end-to-end simulation chain from its stand alone CADFiber and Catia-based CATFiber software, through to multiple finite element-based analyses including structural design, preform draping and preform resin impregnation.

Automotive Composites

“We offer low-cost preforms which are optimized for high-volume processes, including resin transfer molding (RTM) and thermoplastic stamping,” says Coriolis chief technology officer and director Alexandre Hamlyn. But don’t other companies offer this as well? “Yes, but they do not have our background with all of our software development. It took us 15 years to develop our know-how in handling fiber in AFP and in robotic materials software. Our machines are also built using standard, off-the-shelf robots. We have supplied 50 machines and they all have the same basic components. So our approach is more robust.”

Notably, all of the parts made with these machines vary greatly, from automotive to aerospace, large and small, relatively flat and very complex-shaped. “We are not focusing only on dry fiber, thermoplastic or thermoset,” Hamlyn explains. “We can use whatever materials. We can use infrared, hot air or laser heating and any fibers. Our solutions are quite open to new developments and offer the most flexibility but without loss in reliability.”

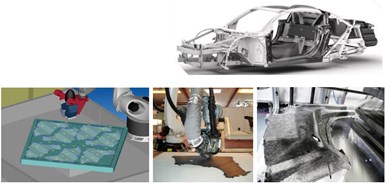

Parts developed for automotive include a door beam for Peugeot, an anti-vibration engine mount for Cooper Standard and a roof and B pillar for Audi. Coriolis has also made a seat frame for Faurecia to benchmark the Quilted Stratum Process (QSP) production line vs. AFP.

Coriolis Composites is part of the Excelcar R&D center and consortium based in Rennes, France which includes Peugeot, Cooper Standard and Faurecia, which all have facilities there, as well as local universities and development authorities. Opened in 2015, this 800-m2 area within the Le Janais plant is focused on development of composites parts to replace metal in order to reduce automobile weight and increase fuel efficiency/reduce emissions.

Coriolis believes it offers key advantages for automated preforming:

- Lower scrap than NCF due to the ability to optimize the preform for closest net shape.

- Highest strength- and stiffness-to-weight ratio due to optimally tailored preform thanks to the ability to place at fibers at any orientation.

- High-volume production:

- 1 kg/hr with single 1.5-inch wide tow/tape.

- 100 kg/hr with 12 x 1.5-inch wide tow/tape.

(e.g. 24k or 50k tow spread to 0.5 to 1.5-inch width)

- Advanced processability:

- Can optimize preform architecture for 3D forming and permeability for resin infiltration via HP-RTM, C-RTM or resin infusion.

- In-situ consolidation of thermoplastics.

- Local reinforcement possible with low-cycle times.

R&D resource

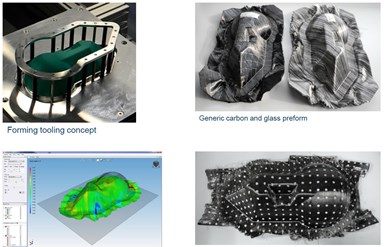

Coriolis tooling development and draping simulation/optimization, where printed dots assist vision system scanning, part of comparing simulation results to real parts for validation. Photo Credit: Coriolis Composites

Coriolis Composites also provides significant R&D capabilities, including an 800-m2 lab with three dedicated machines for trials. Services offered by this Technical Center include:

- Feasibility studies

- Prototyping

- Productivity analysis

- Part and tooling design

- Process development

- Simulation and optimization

- Pre-production runs

- Small series production up to 1,000 parts/yr

Coriolis strengths here include decades of experience, participation in numerous collaborative R&D projects and an extensive suite of simulation tools.

Related Content

Composite rebar for future infrastructure

GFRP eliminates risk of corrosion and increases durability fourfold for reinforced concrete that meets future demands as traffic, urbanization and extreme weather increase.

Read MoreMaterials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

Read MorePrice, performance, protection: EV battery enclosures, Part 1

Composite technologies are growing in use as suppliers continue efforts to meet more demanding requirements for EV battery enclosures.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreRead Next

Automated Preforming, Part 5: Holistic Quality Optimization

Simulation and testing key to integrated approach for optimization of automated preforming, offering time and cost savings as well as basis for automated quality inspection.

Read MoreAutomated Preforming, Part 7: Fill Gesellschaft

Fill automates preforming for 1-min cycle time overmolded thermoplastic automotive parts but supplies automation throughout aero- and autocomposites process chains.

Read MoreComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read More

.jpg;maxWidth=300;quality=90)