CW Blog

Automated robotic NDT enhances capabilities for composites

Kineco Kaman Composites India uses a bespoke Fill Accubot ultrasonic testing system to boost inspection efficiency and productivity.

Read MoreCreating a composite battery insert-stud solution for EV trucks

Bossard worked with an OEM and Tier supplier team to meet tight electrical insulation and packaging tolerances while reducing tooling, molding and assembly costs.

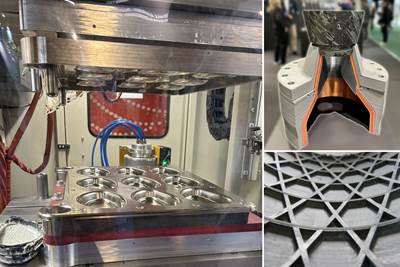

Read MoreJEC World 2024 highlights: Forwarding initiatives surrounding sustainability and mobility

Themes at the forefront of JEC World 2024 included solutions for mobility applications and sustainable materials, technologies and processes for composites manufacturing.

Read MoreComposites end markets: Batteries and fuel cells (2024)

As the number of battery and fuel cell electric vehicles (EVs) grows, so do the opportunities for composites in battery enclosures and components for fuel cells.

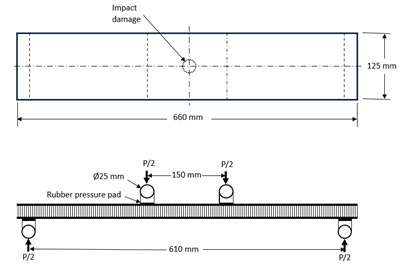

WatchDamage tolerance testing of sandwich composites: The sandwich flexure-after-impact (FAI) test

A second new ASTM-standardized test method assesses the damage tolerance of sandwich composites under flexural loading.

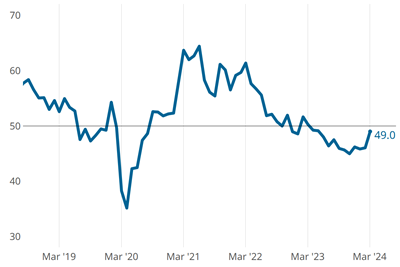

Read MoreComposites industry activity meaningfully slowed contraction in March

The GBI: Composites Fabricating still contracted in March, though it landed just one point shy of 50, which could eventually lead it into expansion territory.

Read MoreOptimizing robotic winding of composite tanks and pipes

Pioneer in mandrel-based reinforced rubber and composite products, TANIQ offers TaniqWindPro software and robotic winding expertise for composite pressure vessels and more.

WatchJEC World 2024 highlights: Thermoplastic composites, CMC and novel processes

CW senior technical editor Ginger Gardiner discusses some of the developments and demonstrators shown at the industry’s largest composites exhibition and conference.

WatchJEC World 2024 highlights: Glass fiber recycling, biocomposites and more

CW technical editor Hannah Mason discusses trends seen at this year’s JEC World trade show, including sustainability-focused technologies and commitments, the Paris Olympics amongst other topics.

Read MoreComposites end markets: Pressure vessels (2024)

The market for pressure vessels used to store zero-emission fuels is rapidly growing, with ongoing developments and commercialization of Type 3, 4 and 5 tanks.

WatchA return to JEC World

CW editor-in-chief Scott Francis reflects on the ways in which the composites industry has changed and also stayed the same based on observations from this year’s JEC World.

Read MoreForvia moves toward more sustainable automotive composites manufacturing

Automotive technology supplier Forvia shares sustainability goals and recent developments aimed at bio-based and recycled materials and ramping up hydrogen tank production for clean mobility.

Watch