U.K. research program explores aligned discontinuous fiber prepreg

A research program in the U.K. is attempting to achieve a fundamental step-change in the composites industry.

A research program in the U.K. is attempting to achieve a fundamental step-change in the composites industry. The High Performance Discontinuous Fibre project (HiPerDiF), which began in December 2017 and runs through 2020, is a program funded by the U.K.’s Engineering and Physical Sciences Research Council (EPSRC). It is exploring an alternate way to produce high-performance carbon fiber composites: start with discontinuous, rather than continuous fibers. The program, led by Professor Ian Hamerton of the Bristol Composites Institute (ACCIS) at the University of Bristol, has an impressive roster of project partners, including Airbus, Toyota, BAE Systems, ELG Carbon Fibre Ltd., Hitachi Chemical Co. Ltd. and several composite material suppliers including Solvay and Hexcel.

The HiPerDiF researchers argue that simplifying and automating manufacturing processes will increase composite part production volumes. And, if greater production volumes means using more carbon fiber, recycling processes are key to recovering and reusing the fiber. In other words, the goal is to develop a high-volume method that can readily, as the group says, “remanufacture” recycled short fibers and produce parts with mechanical properties comparable to continuous fibers, with those parts in turn (if coupled with a thermoplastic matrix) able to be recycled several times.

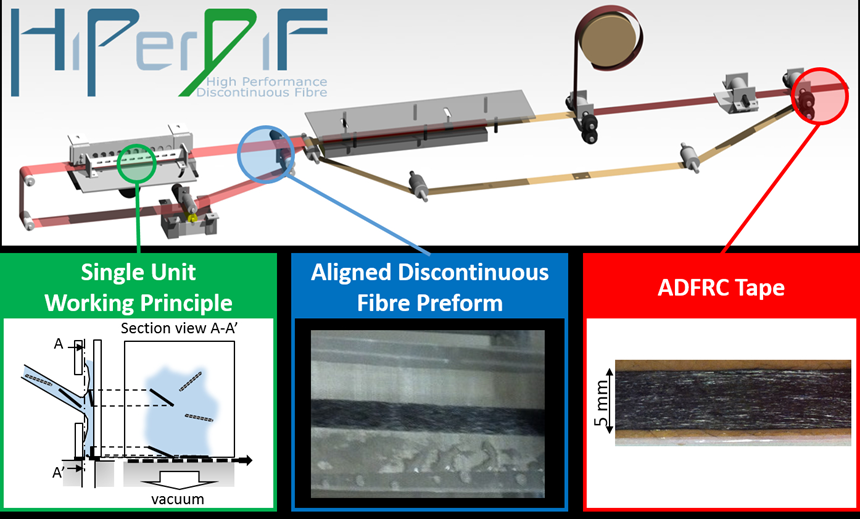

The program’s co-investigative lead, Dr. Marco Longana, explains that HiPerDiF technology is a high-volume manufacturing method, invented at the University of Bristol by Dr. HaNa Yu under an earlier program (HiPerDuct, or High Performance Ductile Composite Technology), that is used to produce high-performance aligned discontinuous fiber reinforced composites (ADFRC). He points out that if discontinuous fibers are accurately aligned and their length is significantly longer than the critical fiber length, then the tensile modulus, strength and failure strain of the obtained composites are comparable to those of continuous fiber composites.

The manufacturing technology, which can handle a range of synthetic and natural fibers with lengths between 1 and 12 millimeters, involves suspending the fibers in water and pumping the water/fiber mixture through a nozzle or nozzles directed toward a gap between two parallel plates. Longana explains that the fiber alignment relies on the sudden momentum change of the fiber suspension when it impacts the furthermost plate. The fibers then fall on a stainless-steel mesh conveyor belt, and the water is removed by suction. This aligned fiber preform is dried via infrared, then combined with either a thermoplastic or thermoset resin to form a prepreg. According to the paper explaining the process, the initial machine prototype produced specimens with 67 percent of the fibers within a ±3° range from unidirectional. By processing 3 millimeter, high-strength carbon fiber, a stiffness of 115 GPa, a strength of 1,510 MPa, and a failure strain of 1.41 percent was achieved, with specimens under tensile load.

The HiPerDiF technology can be used to tailor mechanical behavior of composite materials, via hybridization with glass fibers. The researchers also note that reclaimed fiber, while preserving its stiffness, suffers due to sizing removal, alteration of the fiber surface due to char formation and loss of surface activation that affects fiber/matrix adhesion. HiPerDiF is therefore well-suited for assembling reclaimed fibers into an economically valuable material with high mechanical properties. Hamerton adds that one of the key characteristics that differentiates this work from other projects is the ability to generate high-performance composites from recyclate, potentially recovering both mechanical characteristics and value. This program bodes well for reducing the costs of composites, and carbon fiber.

Learn more details about this project on the Engineering and Physical Sciences Research Council’s webpage

Related Content

The making of carbon fiber

A look at the process by which precursor becomes carbon fiber through a careful (and mostly proprietary) manipulation of temperature and tension.

Read MoreMaterials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

Read MoreThermoplastic composites welding advances for more sustainable airframes

Multiple demonstrators help various welding technologies approach TRL 6 in the quest for lighter weight, lower cost.

Read MoreMaterials & Processes: Fibers for composites

The structural properties of composite materials are derived primarily from the fiber reinforcement. Fiber types, their manufacture, their uses and the end-market applications in which they find most use are described.

Read MoreRead Next

From the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read MoreComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read More