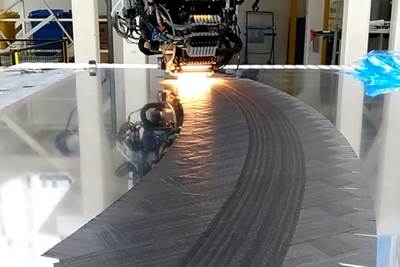

iCOMAT’s Rapid Tow Shearing (RTS) technology relies on in-plane shearing, not in-plane bending, to steer tows. The company says it can shear dry or prepregged tapes 6.35-500 mm wide to a radius as small as 50 mm. Photo Credit: iCOMAT

In early 2020, NASA issued its final report on the Passive Aeroelastic Tailoring (PAT) project, which evaluated the design, optimization and fabrication of a tow-steered wing skin. The report suggested that the material and hardware surrounding automated fiber placement (AFP) systems would need further maturation to help increase the quality and consistency of tow-steered aerostructures. The report also suggested that ancillary technologies be evaluated more closely, and made specific reference to tow shearing.

Continuous tow shearing (CTS) was invented at the Advanced Composites Collaboration for Innovation & Science at the University of Bristol (Bristol, U.K., currently Bristol Composites Institute) in 2010 under an EPSRC grant by Byung Chul (Eric) Kim (primary inventor), Paul Weaver and Kevin Potter. Evangelos Zympeloudis further developed the technology from 2014 onwards at the university and has been leading the commercialization of the technology. iCOMAT (Bristol) was established to commercialize tow shearing in 2019 by Zympeloudis, Kim and the University of Bristol as a spin-off company, with Evangelos as the CEO of the company and Kim as the chief technology advisor. iCOMAT has worked to mature the overall process and recently rebranded it to RTS (rapid tow shearing) to highlight productivity gains that have resulted from this work.

Zympeloudis says tow shearing was developed as an alternative to tow steering, which uses in-plane bending of tows and is prone to defect generation, including tow buckling, overlaps and gaps. He notes that such defects, even if well managed by the AFP machine, must be accounted for in the design to guard against knockdown, which complicates design, fabrication and testing efforts.

iCOMAT instead uses in-plane shearing to move tows laterally as they are placed and re-orient the fibers along a radius. This is accomplished, says Zympeloudis, through the use of intellectual property (IP) in two places: the material and the placement head. “I can’t go into great detail,” he says, “but we do many things to the material before we place it, and the placement head itself is critical to iCOMAT’s shearing technology.

Zympeloudis says iCOMAT’s technology, delivered through a placement head attached to the end of a 6-axis robot, can shear off-the-shelf dry or prepregged materials to a radius as small as 50 millimeters (2 inches) in tape widths ranging from 6.35-500 millimeters (0.25 inch to 19.7 inches). He says dry fibers are most amenable to shearing, but with proprietary modification, prepregged tapes can be sheared as well. “We can shear any UD prepreg we have tried, and we have tried a lot,” Zympeloudis says. “But we have not tested all UD prepregs on the market.”

One notable feature of tapes placed using iCOMAT’s shearing technology is that as the angle of shear increases, lateral movement of the fibers relative to one another causes the tow/tape width to decrease and thickness to increase. This is a feature, says Zympeloudis, that designers have exploited to locally increase the thickness of a laminate, without increasing the number of plies.

Tow shearing avoids the buckling, laps and gaps endemic to traditional tow steering. In addition, as the angle of shear increases using iCOMAT’s RTS technology, tape width narrows while the thickness increases. Note, for example, in the top image, the tape width difference between 0° and 60°. This is a feature that designers have exploited to locally increase the thickness of a laminate, without increasing the number of plies. Photo Credit: iCOMAT

iCOMAT points to several benefits of RTS, including more efficient composites fabrication, reduced waste, better load path management, no gaps or overlaps and no fiber buckling. “It’s a radical way to manufacture with composites that drastically improves structural and production performance,” Zympeloudis says.

The company is currently involved in seven R&D trials with leading OEMs to evaluate RTS and its application. And later in 2021, iCOMAT will place its first system, called RTS 2D, with a customer in a manufacturing environment.

Although RTS appears to be ideally suited for commercial aerospace use — particularly in wing skins — Zympeloudis acknowledges that there is several years worth of design, manufacturing, testing and certification work to be done before shearing technology appears on a commercial aircraft. So, not surprisingly, iCOMAT is targeting defense applications first and hopes to have tow-sheared parts flying by 2023. Zympeloudis also points to automotive as another target. He says RTS could be used to make curved beams for cars and trucks to near-net shape, with minimal waste.

Regarding testing and certification, Zympeloudis notes that there is no established ASTM standard designed specifically for testing steered or sheared fibers. “As soon as you start steering, many of the ASTM standards go out the window, but we think it might be possible to use existing standards, such as ASTM D3039 [standard test method for tensile properties] with RTS. You can go a long way using existing standards, but we are also working to develop dedicated test methods for RTS.”

Related Content

Materials & Processes: Resin matrices for composites

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.

Read MoreNovel dry tape for liquid molded composites

MTorres seeks to enable next-gen aircraft and open new markets for composites with low-cost, high-permeability tapes and versatile, high-speed production lines.

Read MorePlant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreRead Next

AFP tow steering comes of age, Part 1: Current state

It used to be enough that AFP systems could precisely and quickly place and cut multiple tows to build complex aerostructures. Now, fabricators need those tows steered, and the tighter the radius, the better.

Read MoreTow steering, Part 2: The next generation

Wings on next-generation commercial aircraft will be longer, thinner, more aerodynamic and more efficient. They also are ideal candidates for the application of steered tows. One project aimed to design, fabricate and quantify a tow-steered wing skin.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read More

.jpg;maxWidth=300;quality=90)