Topside Applications

A variety of composite products combat corrosion and save weight.

Composite handrails, ladders, gratings, cages, decking, flooring and cable trays have been used on fixed and floating offshore platforms for more than 15 years, with installations on more than 4,000 structures in the Gulf of Mexico alone. Composites have also been adopted over the last several years for personnel protection structures including blast relief systems, firewalls, enclosures, temporary structures and modular housing, as well as for specialized structures like accumulator bottles for riser tensioning systems on tension leg platforms (TLPs).

In topside applications, as elsewhere, the inherent corrosion resistance of composite materials reduces life cycle costs for a project by minimizing maintenance. Special resins can be used that are ultraviolet-, chemical- and algae-resistant. The light weight of composites compared to steel reduces transportation and installation costs. As Alan Reichelt of Alderley Materials Ltd. (Berkeley, U.K.) succinctly states, “The benefit of composites is that they offer, potentially, more than one solution at a time.”

In early use, composites were typically relegated to secondary structures, due to combustion concerns. A breakthrough occurred in June 1998, when the U.S. Coast Guard (USCG), in its Policy File Memorandum (PFM) 2-98, certified the use of phenolic gratings as an acceptable fire-retardant material, having Level 2 (L2) structural fire integrity (see Sidebar). Since then, the American Bureau of Shipping (ABS) has adopted the standard, opening the door to the use of phenolic gratings worldwide.

However, there remains some resistance to composites in topside applications, especially regarding primary escape routes. Today, a better understanding of the variety of available composite products and how they can be integrated into platform design is alleviating some of these reservations.

Read Next

Petrobras Pioneers Topside Composites

Petrobras (Rio de Janeiro, Brazil) was the first major oil company to experiment with molded gratings in the 1980s, though these early products proved unsatisfactory due to wide variations in mechanical properties. However, advances in pultrusion and filament winding technology coupled with the availability of

Read MoreComposite Accumulator Bottles Perform In Service

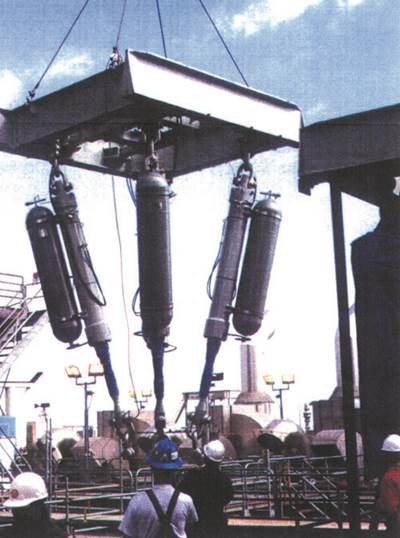

A riser tensioning system for a TLP consists of a tensioning ring and framework, with four to eight hydraulic cylinders — each with an attached pressure vessel or “accumulator bottle” — to support and allow movement of the rigid riser pipe. Installed in the riser wellbay, this primary structural system is desi

Read MoreOther Applications Expand

A growing area in the offshore world is the refitting or “recycling” of older oil platforms to support additional production. A particularly active area for recycling is in the North Sea, where additional pipelines can be run to existing rigs for about $1 million (as opposed to spending $20 million for a new r

Read More

.jpg;maxWidth=300;quality=90)