Three Emerging Technology Trends to Look for at IMTS 2018

Sponsored ContentNot only a display of products, IMTS is an introduction to never-before-seen technology, particularly those on the horizon. Here are a few of the top emerging technology trends and how to find them at IMTS 2018.

Share

According to the World Machine Tool Survey, the machining industry is booming on a global scale, and with strong performance, that means more shops are looking to invest in better tools, better products and ultimately, better processes.

As the current state of the manufacturing industry is positive, it has many setting their eyes forward to the future.

Predicting the future of manufacturing is difficult, predominantly because it requires equal parts visualizing and guessing how certain components of the industry will ultimately fit together. However, the pieces are already here. Some of these concepts may have seemed too lofty and unachievable for small to mid-size job shops. But now, trends such IIoT (Industrial Internet of Things) have become less of a buzzword and more of a necessary step toward increasing productivity and profitability.

No event captures the scope and energy of emerging technology like IMTS 2018 – The International Manufacturing Technology Show produced by AMT – The Association For Manufacturing Technology.

Kicking off September 10-15 in Chicago, Illinois, IMTS is where thousands of exhibitors, visitors and industry leaders of every kind come together to discover new and emerging technology.

Not only a display of products, IMTS is an introduction to never-before-seen technology, particularly those on the horizon.

Here are some of the top emerging technologies at the forefront of this year’s event:

1. Digitalization

At the heart of the Industry 4.0 trend is digitalization. Achieving a more digitally connected shop can take the form of data connection and collection, system monitoring and management, and using digital technology to improve the systems your shop relies on.

Interconnectivity is about more than just high-tech software. It’s about taking seemingly futuristic or out-of-reach ideas—such as augmented reality (VR), voice control technology, or even company-wide data management—and applying them to real, shop-floor scenarios.

Dedicated to just that is AMT’s Emerging Technology Centers (ETC) sponsored by AMT—The Association for Manufacturing. As one of two at this year’s show, the ETC dedicated to Digital Transformation in the North Building lets you see it in action and discover examples of how businesses in aerospace, automotive, medical and energy sectors are implementing these innovations. Visitors can witness a real-world example of a physically and digitally connected machine tool, robot arm and coordinate measuring machine (CMM).

Here, visitors can learn about how to boost overall equipment effectiveness and improve productivity. Open standards like the MTConnect® protocol and the ROS-Industrial (Robotic Operation System) architecture, both of which are featured in the ETC, lower the barrier for operations that want to coordinate data flow and data management between different models and makes of equipment.

Visitors can also gain insight into many aspects of the digital manufacturing chain, from free operating standards for machine shops and connected machines to cyber security, developed by leading technology organizations including:

- iT SpeeX “Athena” – an intelligent assistant application for machine shops.

- Cisco

- Hexagon Manufacturing Intelligence

- Hurco Companies, Inc.

- The MTConnect® Institute

- The ROS-Industrial Consortium

- SwRI

- Universal Robots

- VIMANA

- NIST

Ultimately, digitalization means using data to perform better on every level of the manufacturing process, leading to smarter, more informed business decisions.

Learn more in the North Building ETC focusing on Digital Transformation, Booth #236700.

Scott Volk – Vice President, MetalQuest Inc.

2. Automation

Automation is just one component of Industry 4.0 and a method for achieving a more digitally connected shop. Often identified as “disruptive technology,” automation has changed the way products are developed, built and delivered.

Many are already doing a good job of implementing automation with machinery, such as adding robot loading and part removal, or automatic material feed systems. Some are introducing “cobots” or collaborative robots that are able to safely work alongside operators. The next step is automating the entire workflow, covering every step of the way from part handling, machining, finishing, to inspection.

One common misconception is that automation is reserved for those in high-volume part production. Those outside that scope might feel these applications don’t apply to them. The reality is that automation can be applied to everyday tasks, and these seemingly small improvements can make a major impact.

It’s easier than ever to get started. More automation equipment manufacturers are introducing plug-and-play products that make the implementation process faster and easier, allowing shops to add automation seamlessly into existing processes.

The advantages are not just in cycle time reductions. Implementing more automation provides the freedom to adapt as the technology continues to evolve. With automation, machines become more capable, more reliable, and as a result, are more prepared for whatever changes come next.

Looking to see it in action at IMTS? Robots and other automation can be found prominently featured in nearly every hall at the show, a testament to automation’s various forms and applications.

You can also take a deep dive into integrating automation at the Global Automation & Manufacturing Summit co-located at IMTS. Presented by Hannover Messe USA, the conference sessions place an emphasis on data integration alongside robotics.

Jason Zenger – President, Zengers Industrial Supply

3. Additive Manufacturing

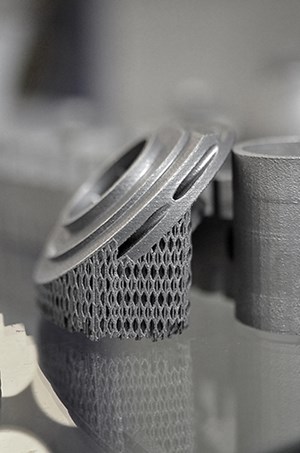

Additive manufacturing has become an increasingly popular application for several reasons. For one, it’s changing the way machinists look at some of the most complex part challenges, opening up new and lucrative business opportunities. But more concretely, it can offer serious cost advantages.

Since the world’s first additive manufactured vehicle, the Strati, was built at IMTS 2014, innovations in additive have continued to headline IMTS and does so this year with AMT’s Emerging Technology Center dedicated to Additive Manufacturing, located in the West Building, Level 3; Booth #431609.

IMTS visitors will encounter demonstrations of the newest breakthroughs in materials, speeds and technologies recently developed by Oak Ridge National Laboratories (ORNL), public-private collaborations and exhibiting additive manufacturers.

The Die-in-a-Day Scavenger Hunt will be led by Oak Ridge National Laboratory (ORNL) and take participants through the process of creating an additively manufactured tool, from design and prototype production to final inspection.

Also hosted in AMT’s Additive Manufacturing ETC are America Makes members who will be on hand at the America Makes Knowledge Bar to present a variety of topics tailored to those working in Additive Manufacturing and related technologies. The America Makes Digital Storefront—a secure online platform to help member manufacturers learn, connect and adopt additive technologies—will also be presented.

Visitors to the Knowledge Bar can interact with additive experts and gain valuable insight into how America Makes and its members are accelerating the adoption of this exciting technology. (America Makes is the National Additive Manufacturing Innovation Institute and the first Institute within the Manufacturing USA infrastructure and is driven by the National Center for Defense Manufacturing and Machining (NCDMM).)

The demand for additive technology has grown as more and more shops are using it as a fast and cost-efficient way to produce tooling, build jigs, fixtures and other tools. Others are already beginning to explore how to integrate 3D printing systems into existing operations and use it for future product development.

Checkout the latest in additive trends in the Additive Manufacturing Pavilion in the West Building, Level 3, which has nearly tripled in the number of exhibitors since the last show.

Tom and Julie Hoban – JTD Enterprises

How to Find These Trends in Action

1.3 million square feet of exhibit space can be a lot to tackle, so it’s important to plan ahead. Find the emerging technology that fits your shop’s interests by first determining what you need to see and what you want to see.

IMTS Pavilions help break down exhibitor technology by specific processes. These include:

- Abrasive Machining/Sawing/Finishing

- Additive Manufacturing

- Controls & CAD/CAM

- EDM (Electrical Discharge Machining)

- Fabricating & Lasers

- Gear Generation

- Machine Components/Cleaning/Environmental

- Metal Cutting

- Quality Assurance

- Tooling & Workholding Systems

Find the MyShow Planner as a feature of the IMTS app, now available free for iOS and Android devices.

Organize your trip with MyShow Planner, a free, Web-based application that combines planning and logistics into one easy-to-use tool from your mobile device, laptop or desktop computer. This trade-show tool maps out your entire trip and organizes your itinerary and appointments in one place.Use it to find exhibitors, consolidate attractions by location and produce a schedule of events based on your selections.

The Smart Manufacturing Hub, produced by SME and AMT, further embodies emerging technology at IMTS by offering exclusive presentations on the most advanced and innovative solutions being used in the industry. Hourly presentations will cover topics such as 3D Printing, Robotic Automation and ROI, digital machining, Industry 4.0, improving product development, and using IoT data.

Gain access to critical info and insight from conferences at IMTS, where you can learn more about the technologies above straight from leading experts in the industry. The IMTS Conference runs Monday, September 10, to Thursday September 13, 2018, and offers a 4-day deep dive into topics such as:

- Manufacturing Process Innovations

- Alternative/Additive Manufacturing

- Plant Operations

- Quality/Inspection/Metrology

- Systems Integration/Industry 4.0/IIoT

IMTS also includes several co-located conferences and presentations:

- Additive Manufacturing Conference

- AppliedAM – Where Additive Minds Meet

- Digital Transformation Conference

- GAMS (Global Automation Manufacturing Summit)

- OPC Foundation Conference

- Integrated Industries

- Industrial Laser Conference

- Top Shops Workshop

Emerging technologies like those above are no longer reserved for the industry elite. Today, several machine shops have already begun to realize the gains from implementing one or more of these trends, and the others simply cannot afford to be left behind.

To learn more about emerging technology and how to find it, visit imts.com.