Studies Support Viability Of Composites

Numerous studies have compared the performance and cost of steel and composite tendons. Conoco, Norske Conoco A/S (NCAS) and KOP headed several projects to qualify composite TLP tethers prior to launching a full sea test. In a recent study, they compared steel and composite TLP systems in water depths up to 9,

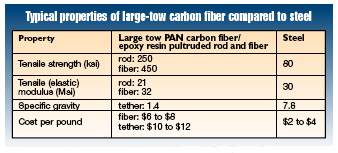

Numerous studies have compared the performance and cost of steel and composite tendons. Conoco, Norske Conoco A/S (NCAS) and KOP headed several projects to qualify composite TLP tethers prior to launching a full sea test. In a recent study, they compared steel and composite TLP systems in water depths up to 9,900 ft/3,000m using environmental criteria for the Gulf of Mexico and West Africa. The composite tether they evaluated was based on their CompTether design, which is composed of small diameter large-tow carbon fiber rods pultruded with epoxy resin

Conoco/KOP determined that, on average, a composite component has a 50 percent higher cost than its steel equivalent, but weighs half as much. The increased component cost is offset by reduced payload, maintenance, and handling requirements. They concluded that, even at depths of 2,600 ft/800m, the total capital cost of a TLP with both composite risers and tendons was 11 percent lower than that of a steel-tethered TLP, largely due to the reduced installation cost. For installations at 6,600 ft/2,000m, the savings increased to 25 percent. Reduced life-cycle costs related to improved corrosion and fatigue performance were not considered in the study, but would certainly add to these savings.

These results tally with a 1998 cost simulation performed on composite cable manufactured by partners Freyssinet ( Velizy, France), Soficar (Abidos, France), Doris Engineering (Paris, France) and the Institut Français du Pétrole (IFP). Olivier Andrieux, project engineer for Doris Engineering, summarizes the findings: “Using carbon cables as tethers for Mini-TLPs (from 10,000 to 20,000 ton displacement, for example) located in the Gulf of Guinea will allow reduction of procurement and installation costs compared to a steel tubular tether solution beginning at a water depth of around 2,300 ft/800m. Moreover, it will extend mini-TLP depth limits to 10,000 ft/3,000m in the same environmental conditions. These advantages are provided not only by carbon low density (around 1.5 for the overall cable, including the thermoplastic sheath) but also by excellent mechanical properties (tensile stress is three times higher than steel, fatigue resistance more than ten times).” The installation advantages also include a reduced number of required sea-floor anchorages.

Aker Maritime ASA (Norway) and CSO Aker Maritime compared the performance of steel and composite tendons for two typical Gulf of Mexico TLPs operating at a depth of 7,000 ft/2,050m. Presented at the May 1999 Offshore Technology Conference, the study showed that heavy tow carbon fiber composite tendons led to a significant reduction in TLP hull size. The lower tendon weight contributed to reduced drag load on the smaller-diameter composite tendons and reduced current drag and mean wave drift loads on the smaller TLP hull. The net wet weight of 16 composite tendons was 110 tons/100 tonnes (compared to 281 tons/255 tonnes for steel) due to a higher horizontal stiffness per unit of pretension. These reductions, coupled with reduced installation and inspection costs, could lead to significant cost savings.

Composite tendons also showed improved tendon dynamics, platform response, and fatigue resistance over steel tendons. Global performance improvements included reductions in column height (about 3 ft/1 m), maximum horizontal offset (about 10 percent), dynamic tendon tension (about 10 percent), and peak top tension (28 percent). The bending stress was minimal compared to steel and could be practically eliminated by using multi-strand composite rope tendons. Maximum load on the foundation piles was reduced by 25 percent. Smaller foundation piles translate into further cost savings.

The heave natural period (HNP) is a measurement of the vertical motion of the TLP caused by wave energy. For a TLP with steel tendons, the HNP is traditionally held to about four seconds, which minimizes platform resonance and fatigue loading of the steel. Carbon fiber tendons allow the HNP to be relaxed somewhat because the material can withstand greater dynamic motion and fatigue loading. “A composite tether can handle higher fatigue loading,” says Salama. “Steel cannot.”

The Aker study found that the HNP of a TLP moored with composite tethers increased to 4.72 seconds, compared to 4.2 seconds for a TLP tethered with steel tendons. The Conoco/KOP study found that, given the superior property and performance characteristics of composite tendons, the HNP of a TLP could be relaxed to 5.5 seconds without significantly affecting the tendon’s strength, fatigue life, or dynamic motion characteristics.

Related Content

Natural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

Read MoreMaterials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

Read MoreASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MorePlant tour: Middle River Aerostructure Systems, Baltimore, Md., U.S.

The historic Martin Aircraft factory is advancing digitized automation for more sustainable production of composite aerostructures.

Read MoreRead Next

Composite Tether Goes To Sea

Conoco and KOP have manufactured a prototype of a carbon fiber composite tether that could extend TLP production to depths exceeding 10,000 ft/3,000 m. The design has undergone extensive static testing and fatigue loading and has been verified through hydrodynamic model testing. Sea testing is being planned.

Read MoreDesign Issues With Tendons

A composite tendon is essentially a rope made from small-diameter rods, which are pultruded with carbon fiber. Multiple rods are gathered together and twisted slightly to form a strand, using typical wire rope stranding methods. Depending on the performance requirements, 10 to 40 strands, about 2 to 3 inches/5

Read More

.jpg;maxWidth=300;quality=90)