So, you want to make automotive composites . . .

Materials and manufacturing processes for autocomposites are evolving rapidly, and CompositesWorld wants to help you sort it out. A free, March 29 webinar is designed to help bring you up to speed on the manufacturing technologies best suited for autocomposites.

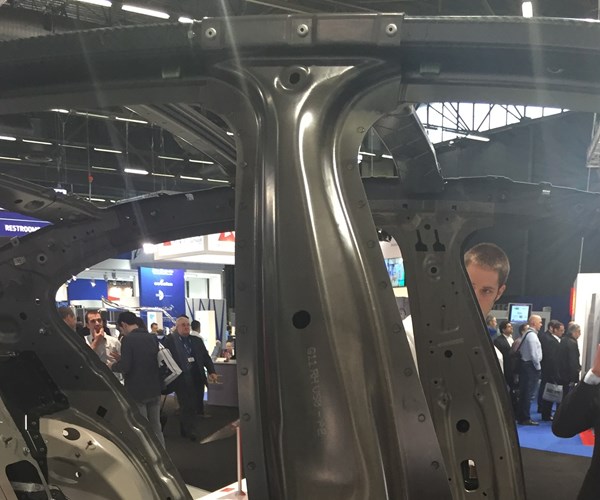

BMW 7 Series carbon fiber composite B pillar.

High-rate manufacture of structural automotive parts has long been the Holy Grail of the composites manufacturing industry. That highly coveted day is, by all accounts, not quite here yet. By the same token, however, composites are also no longer restricted to use in exorbitantly priced Lamborghinis, McLarens and Ferraris. Today, they are finding application in a variety of parts for several mid-rate production vehicles, and there is promise of more to come.

Fiber, resin and equipment suppliers, meanwhile, have been hard at work developing new products to meet the quality and cycle time demands of automotive OEMs. The result is a highly dynamic autocomposites supply chain that can be dauntingly difficult to monitor and make sense of.

CompositesWorld, as part of its 1-Minute Cycle Time Initiative, is presenting a free, one-hour webinar designed to provide to composites professionals and automotive OEMs the very latest on materials and equipment for automotive composites manufacturing. “Materials and Processes for High-Volume Autocomposites Manufacturing” will be presented on March 29 at 2:00 pm ET.

Webinar topics to be covered include fiber types and formats, snap-cure resins, thermoplastic resins, injection overmolding, resin transfer molding (RTM), sheet molding compound (SMC) and compression molding. The presentation will provide basic information on how materials and technology are being applied, as well as an assessment of where these technologies are headed.

Presenters are Sara Black, senior editor; Ginger Gardiner, senior editor; and Jeff Sloan, editor-in-chief. For more information, and to register for the webinar, visit “Materials and Processes for High-Volume Autocomposites Manufacturing.”

Related Content

-

Price, performance, protection: EV battery enclosures, Part 1

Composite technologies are growing in use as suppliers continue efforts to meet more demanding requirements for EV battery enclosures.

-

Protecting EV motors more efficiently

Motors for electric vehicles are expected to benefit from Trelleborg’s thermoplastic composite rotor sleeve design, which advances materials and processes to produce a lightweight, energy-efficient component.

-

Materials & Processes: Resin matrices for composites

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.