Scottish rocket facility unveils advanced materials production methods

Orbex offered a peek into its Scotland-based rocket facility, unveiling its carbon fiber winding equipment and 3D printed single piece rocket engines, as well as its new Mission Control Centre.

Orbex headquarters in Forres, Scotland. Source | Orbex

In November, Scotland-based spaceflight company Orbex (Forres, U.K.) offered a peek into its rocket factory, sharing photos of how the company is using advanced engineering techniques and materials to create next-generation, renewably-fuelled orbital launch vehicles.

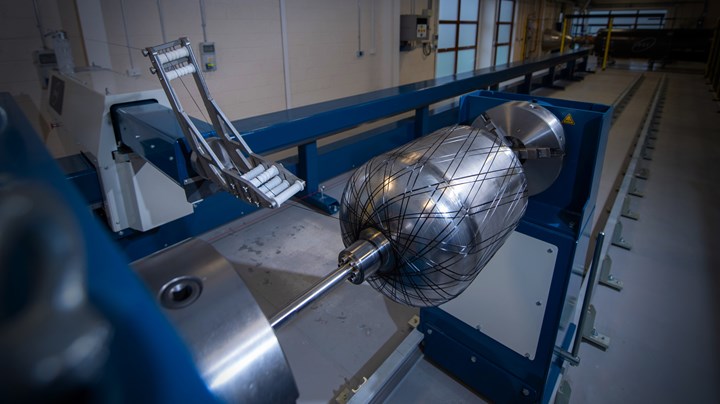

Orbex’s 18-meter long carbon fiber winding machine is said to be one of the largest such machines in Europe. Source | Orbex

Several new production systems have been installed at the facility, including an 18-meter long carbon fiber winding machine that automates the rapid weaving of materials to build the main rocket structures. Orbex says it has worked for several years to perfect the carbon fiber blend used in the patented construction of its Prime rocket, which is said to be 30% lighter than similar sized rockets, allowing acceleration from 0 to 1,330 km/h in just 60 seconds.

Orbex Prime Source | Orbex

The company uses a full-scale autoclave to bond the carbon fiber composite structures which comprise large rocket parts including main stage fuel tanks.

Earlier this year, Orbex announced it was using 3-D printing to create single-piece rocket engines, integrating design details and features without requiring additional processing time. The company says it is able to 3-D print a complete rocket engine in just five days.

“We’re creating rockets in a way that hasn’t been done before,” says Chris Larmour, Orbex CEO. “The whole point of NewSpace — private enterprise getting involved in spaceflight — is to provide faster, better and cheaper access to space. Burning through hundreds of millions of dollars on robotic assembly lines or hundreds of staff to produce heavy, metal rockets is an antiquated approach. Building a modern space business means updating the manufacturing ethos to be faster, more agile and more flexible.”

According to Orbex, while some launch solutions for small satellites require up to 200,000 kilos of fossil fuels, Prime needs just 4,000 kilos of fuel per launch, making it around fifty times more fuel efficient. Prime will use bio-propane, a clean-burning and renewable fuel that reduces carbon emissions by 90% compared to standard kerosene-based rocket fuels. It also avoids using hazardous substances such as hydrazine or highly concentrated hydrogen peroxide. Prime rockets are also designed to leave no orbital debris and to be re-usable, using an innovative low mass concept to recover the main stage.

The company also unveiled its new Mission Control Centre that will be used to monitor orbital rocket launches from Scotland and other sites, as well as engine tests from its two propulsion test sites. The company is currently working to get approval for Sutherland spaceport in northern Scotland, a facility that would be shared with Rocket Lab (Huntington Beach, Calif., U.S.) for launch of its composite Electron rocket, though the companies would use different launch pads.

Related Content

-

Materials & Processes: Tooling for composites

Composite parts are formed in molds, also known as tools. Tools can be made from virtually any material. The material type, shape and complexity depend upon the part and length of production run. Here's a short summary of the issues involved in electing and making tools.

-

Materials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

-

Clean Sky 2 OUTCOME project demonstrates PEEK thermoplastic composite wingbox cover

Airbus Defense and Space, FIDAMC and Aernnova demonstrate out-of-autoclave, one-shot process for wingbox cover with integrated stringers for regional aircraft.

.png;width=70;height=70;mode=crop)