SAMPE 2010 Seattle at a Glance

A quick-reference timetable for the Society for the Advancement of Material and Process Engineering's SAMPE 2010 Conference and Exhibition, May 17-20, in Seattle, Wash.

The following schedule is based on information available from SAMPE on April 23, 2010. To view the rest of our SAMPE 2010 coverage, see "Editor's Picks," at right.

Monday, May 17

Registration 7:30 a.m. to 5:00 p.m.

Tutorials 9:00 a.m. to 12:00 p.m.

• Damage Tolerance and Assessment

• Nanotechnology – Overview

• Out of Autoclave Processing

• Dimensional Control and Process Modeling

Tutorials 2:00 p.m. to 5:00 p.m.

• Test Methods for Composites

• Composite Repair Technology

• Composite Manufacturing Technology

• Composite Tooling

Sessions 2:00 p.m. to 5:00 p.m.

• Nanocomposites I (ITAR)*

• Morphing Materials (ITAR)*

• Design for Impact

• Structural Health Monitoring

• Resins

• Sandwich Structures

SAMPE Fellow Banquet 6:00 p.m.

Tuesday, May 18

Registration 7:30 a.m. to 5:00 p.m.

Exhibit Hall Open 10:00 a.m. to 5:00 p.m.

Keynote Presentation 8:00 a.m. to 9:00 a.m.

Carbon Nanotube-incorporated Polymeric Nanocomposites:

Morinobu Endo (Shinshu University, Japan)

Featured Lecture 9:00 a.m. to 9:30 a.m.

Design and Manufacture of Composites on Military Aircraft:

Dr. John Russell (Air Force Research Lab)

Sessions 9:00 a.m. to 12:00 p.m.

• Testing

• NDE/NDI I

• Thermoplastic Composites I (ITAR)*

• M&P I (ITAR)*

• Out-of-Autoclave I

• Novel Materials and Applications

• Composite Process Modeling I

• Manufacturing I

• Adhesion & Adhesive Bonding I

• Student Symposium I

Panel 9:00 a.m. to 12:00 p.m.

• Commercialization of Nanotechnology

Featured Lecture 2:00 p.m. to 2:30 p.m.

Design/Analysis Trends in Aerospace

Composite Structures

Eric Cregger (The Boeing Co.)

Sessions 2:00 p.m. to 5:00 p.m.

• Nanocomposites II

• Design & Analysis I

• Thermoplastic Composites II

• M&P II

• Out-of-Autoclave II

• Novel Architectures, Hybrids, and

Coatings (ITAR)*

• Composite Process Modeling II

• Manufacturing II (ITAR)*

• Adhesion and Adhesive Bonding II

• Student Symposium II

Panel 2:00 p.m. to 5:00 p.m.

• Benchmarking of Composites

Welcome Reception 5:00 p.m. to 6:00 p.m.

Wednesday, May 19

Registration 7:30 a.m. to 5:00 p.m.

Exhibit Hall Open 10:00 a.m. to 5:00 p.m.

Keynote Presentation 8:00 a.m. to 9:00 a.m.

New Materials & Processes Driving Boeing’s Products

Frank Doerner (The Boeing Co.)

Featured Lecture 9:00 a.m. to 9:30 a.m.

Composites in Canada

Dr. Andrew Johnston (National Research Council Canada)

Sessions 9:00 a.m. to 12:00 p.m.

• Thermoplastic Composites III

• Adhesion & Adhesive Bonding III

• Nanocomposites III

• Design & Analysis II

• Rotorcraft I

• NDE/NDI II

• M&P III

• Liquid Molding Processes I

• Aircraft Applications I

Panel 9:00 a.m. to 12:00 p.m.

• Out of Autoclave Processing — Challenges and Opportunities

Featured Lecture 2:00 p.m. to 2:30 p.m.

Natural Materials

Mohini Sain (University of Toronto)

Sessions 2:00 p.m. to 5:00 p.m.

• Space Applications (ITAR)*

• Repair I

• Nanocomposites IV

• Design & Analysis III

• Rotorcraft II

• NDE/NDI III

• Natural Materials

• Liquid Molding Processes II

• Aircraft Applications II

Panel 2:00 p.m. to 5:00 p.m.

• Frontiers in Materials and Process Technology

Student Social Reception 5:00 p.m. to 6:00 p.m.

Thursday, May 20

Registration 7:30 a.m. to 2:00 p.m.

Exhibit Hall Open 9:00 a.m. to 12:00 p.m.

Featured Lecture 8:00 a.m. to 8:30 a.m.

Wind Energy

Dr. Enrique Garcia (Gamesa SA)

Featured Lecture 8:30 a.m. to 9:30 a.m.

Innovation: The Modern Energy Challenge

Dr. Ian Chatting (Vestas Wind Systems)

Sessions 9:00 a.m. to 12:00 p.m.

• Nanocomposites V

• Tooling

• Fracture and Failure

• Electromagnetic Effects (ITAR)*

• High Temperature / Liquid Molding (ITAR)*

• Recycling

• Wind Energy

• Nanocomposites VI

Panel 9:00 a.m. to 12:00 p.m.

• Advanced Composite Structural Repair Systems for the Future

Luncheon 12:30 p.m. to 2:00 p.m.

Sessions 2:00 p.m. to 5:00 p.m.

• Nanocomposites VII

• POSS Nanostructures

• Automated Fiber Placement

• Textiles

• Unmanned Systems

• Ceramics

• Repair II

• Nanocomposites VIII

Panel 2:00 p.m. to 5:00 p.m.

• Tooling for Composites: New Materials and Recent Trends

*Papers subject to ITAR (International Traffic in Arms Regulations) are export-restricted. Attendees must present appropriate ID and paperwork.

Related Content

Drag-based wind turbine design for higher energy capture

Claiming significantly higher power generation capacity than traditional blades, Xenecore aims to scale up its current monocoque, fan-shaped wind blades, made via compression molded carbon fiber/epoxy with I-beam ribs and microsphere structural foam.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreMoving toward next-generation wind blade recycling

Suppliers, fabricators and OEMs across the composite wind blade supply chain ramp up existing technologies, develop better reclamation methods and design more recyclable wind blades.

Read MoreMaterials & Processes: Fibers for composites

The structural properties of composite materials are derived primarily from the fiber reinforcement. Fiber types, their manufacture, their uses and the end-market applications in which they find most use are described.

Read MoreRead Next

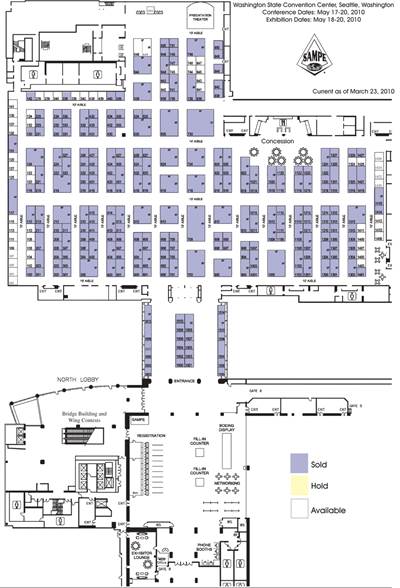

SAMPE 2010 Seattle Exhibitor List

A list of exhibitors, booth assignments and a show floor map for the SAMPE 2010 Seattle trade show, May 17-20, 2010.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read More

.jpg;maxWidth=300;quality=90)