Real-time automated ply inspection (RTAPI) system: CW’s series on automated inspection methods

More composites being used in aircraft, and the pressure for higher production rates means new technologies for automated, in-process inspection while the part is being fabricated. Groups around the world are working on this, and making great strides.

Automated fiber placement (AFP) layups can now be automatically inspected in real time.

Anyone reading this blog probably knows that fast, efficient automated fiber placement (AFP) and automated tape laying (ATL) is actually not very fast and efficient, at least during the making of aerospace parts. Why? Because careful visual inspection and verification is needed after each ply, by trained human inspectors, to meet quality assurance requirements. See this link (https://www.compositesworld.com/articles/archive?id=a7f83f48-23ab-4b1d-8f19-075150dfee2b) for our November 2013 issue, which shows an inspector with a magnifying glass inspecting a small area of the 34.5m-long wing spar for the A350, which puts manual inspection into perspective.

For a large composite part such as a fuselage barrel requiring hundreds of plies, the impact of inspection (and any rework) on automated process efficiency is significant, according to information presented at recent industry gatherings. For example, in a paper presented several years ago by Robert Harper of Fives Cincinnati (Hebron, KY, US) and Allen Halbritter of The Boeing Co. (Chicago, IL, US), based on a generic fuselage barrel and using an optimized AFP process, inspection and rework still made up more than 60% of the total part production time.

That situation is now changing, for several reasons. More composites being used in aircraft, and the pressure for higher production rates means new technologies for automated, in-process inspection while the part is being fabricated. Groups around the world are working on this, and making great strides in technology development, to make inspection as fast as the process itself. “We’ve got to get rid of an 18th century methodology being used for a 21st Century part,” asserts David Maass of Flightware (Guilford, CT US). CW is in the process of gathering information about these new automated inspection processes, and plans to publish a series of articles in print (in CompositesWorld magazine) as well as in Blogs to bring these technologies to light. This blog, featuring Flightware’s RTAPI inspection system, is the first in this series to appear.

“It’s been said that automated inspection is ‘low-hanging fruit’ and the easiest way to really reduce aerospace AFP part production time,” says Maass. His Real Time Automated Ply Inspection (RTAPI) system consists of a laser profilometer, available commercially off-the-shelf, which measures the height of a composite tow band deposited by an automated layup head. “The line scanner, or profilometer, is a very powerful but very low-cost sensor, which is improving all the time,” he adds, citing Keyence (Osaka, Japan) as one well-known source for such scanners, which are used in a huge array of industries including food processing.

The profilometer is a sensor containing both a laser line generator and a camera. The sensor collects measurements of height and width points (about 1,000 points for every tow course) and delivers point cloud data to a software program and user interface that Maass has developed, which converts the data into layup features of interest such as tow edges, tape ends (adds and drops), gaps, overlaps, etc. Working first with Fives Cincinnati (Hebron, KY, US), and now with Automated Dynamics (ADC, Niskayuna, NY, US), Maass’ system mounts the profilometer directly on the layup head. In the case of Fives, a Viper 7000 automated fiber placement (AFP) gantry machine, with a 16-tow head, was used, and more recent proof of concept demonstrations used ADC’s thermoset AFP head on a robotic arm. “The profilometer measures the heights of the fiber tows following the compaction roller, generating millions of data points for each course in a very dense point cloud,” states Maass, adding that the data-processing step of the RTAPI technology is patented. In early work, the system was capable of detecting all features of a single course in fewer than 10 seconds, but in recent work that time is being reduced to near real-time operation. Because the amount of data is so large, parallel processing is needed, that is, multiple computer cores or CPUs working in parallel. Today’s work stations can offer as many as 100 CPU cores on one machine for an affordable price, and more cores can be rented through the Cloud if needed, although this is probably not necessary, says Maass: “By intelligently parceling out the computing workload to many cores operating in parallel, the total time to process a large data flow can be reduced drastically compared with a conventional 4-core PC that most of us use for our desktop machines,” he points out.

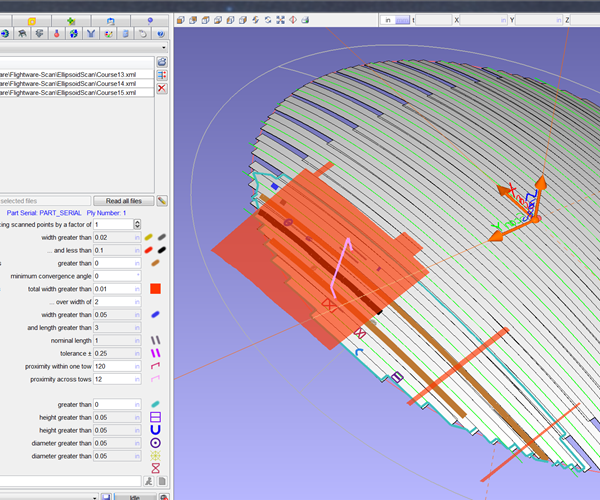

RTAPI software displays layup flaws of the layup shown in the opening photo.

The software compares the as-made layup against the automated machine’s part design program to detect gaps, overlaps, mislocated plies, late adds, foreign object detection (FOD) and more, explains Maass. By analyzing the very large 3D point clouds, the RTAPI software has been shown to detect key features of the layup: tow edges and tow add/drop locations. Flightware worked with CGTech (Irvine, CA, US) to adapt their industry-leading VCP AFP programming software to read and display layup flaws automatically detected by the RTAPI system. The VCP program graphically displays the part layup and all flaws and their location for the ply under construction. Flaw types are shown using symbology and color codes to the operator knows where to look and what to look for. Instead of spending most of his or her time looking for flaws, now he or she proceeds directly to repairing the flaw if necessary and moving on to the next ply.

User flaw tolerance such as maximum allowed gap, distance between splices, etc. are easily and quickly defined in the system graphical user interface (GUI) and stored. Every customer has its own accept/reject limits, and the system was designed to accept and allow any QA criteria the operator selects. Take a look at this YouTube video produced by Maass, which shows how the software works to identify problem tows:

Now, says Maass, Flightware is working on being able to find many more types of flaws, even faster, including edge of ply (EOP) violations or two tape splices located within 12 inches in the same ply, for example: “We are currently working on writing algorithms to identify buckled tows, bridged tow, FOD, twisted tape and fuzzballs.”

The API (Automated Ply Inspection) technology was first developed in 2014 under a NASA-funded program. More recently, DoD’s Defense Logistics Agency (DLA) has funded this work to enable “real-time” operation (hence the acronym RTAPI). The current program includes funding to demonstrate the system on actual, complex aerospace parts. The plan is to build several parts with ADC’s AFP machine (with RTAPI capability), and inspect the layups two ways: manually (current practice) and using the automated system while the part is layed up. This enables RTAPI’s performance to be measured in relation to missed detections (escapes) and false positives. The system will not be useful unless those metrics are very low, and customers will need hard evidence that RTAPI is reliable enough before it will replace a human inspector, explains Maass. Manual inspection time will also be recorded, as this is also important for calculating the savings offered by RTAPI and the corresponding return on investment.

Flightware is actively looking for an aerospace firm with an AFP part, where RTAPI can be of benefit, and to whom the system can be demonstrated. Maass says this system demonstration is scheduled to be performed next year. Flightware intends to license the software to interested parties, and says his company is looking to collaborate with interested machine manufacturers to customize the sensor installation to specific machines. The current DLA project is funded through 2019, so manufacturers will have ample opportunity to work with the system.

Watch CW Blogs for more on automated, in situ inspection methods for ATL and AFP processes, and CW magazine for additional coverage, starting in the February 2018 issue.

Related Content

The state of recycled carbon fiber

As the need for carbon fiber rises, can recycling fill the gap?

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreNovel dry tape for liquid molded composites

MTorres seeks to enable next-gen aircraft and open new markets for composites with low-cost, high-permeability tapes and versatile, high-speed production lines.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreRead Next

CW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read MoreComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read More

.jpg;maxWidth=300;quality=90)