Rapidly approaching: Carbon fiber's seminal event

The 17th-annual Carbon Fiber conference is just weeks away (Dec. 8-10) and it's time to register if you haven't done so. This year's conference marks the return of Chris Red's carbon fiber supply and demand report, and we will also hear from Boeing's director of 777X wing manufacture.

Carbon fiber tows during the manufacturing process.

There are few composites industry events that have the quality and staying power of CompositesWorld's annual Carbon Fiber conference. This year marks the 17th Carbon Fiber conference and will be held Dec. 8-10 at the Knoxville Convention Center in Knoxville, TN, US.

If you've not registered yet, you still have time. But only a few weeks.

Carbon Fiber's location in Knoxville is not a coincidence. Its proximity to Oak Ridge National Labs (ORNL) gives the conference special access to people and facilities that are at the forefront of carbon fiber research and development in everything from aircraft to cars to wind blades to consumer products. In addition, the conference every year attracts a strong, engaged core of carbon fiber professionals — presenters and attendees — who make the event one of the industry's must-attend events.

Included in this year's conference is a panel featuring representatives from the Institute for Advanced Composites Manufacturing Innovation (IACMI) who will discuss that consortium's efforts to reduce costs and increase manufacturing speed in a variety of composite end markets and applications.

The panel will be moderated by Craig Blue, CEO of IACMI. CW caught up with Blue at CAMX and talked to him about IACMI new training partnership with Composites One and Magnum Venus Products, which aims to reach out to young composites enthusiasts with a series of four regional training session in 2016:

December 8:

- Pre-conference seminar: Carbon Fiber Supply and Demand (see details below)

- ORNL Manufacturing Demonstration Facility tours (morning and afternoon); birthdate and residency information required; registration deadline, Nov. 20.

December 9:

- Keynote: Composites for Clean Energy

- Industrial Carbon Fiber Applications in Wind and Transportation Systems, Opportunities Abound

- Ushering in the Carbon Fiber Century – An Industrial Evolution

- The Future of Automotive Lightweighting: Building Case of 2025 and Beyond

- How to Give the Market “Affordable Carbon Fiber”

- Investment Opportunities in the Carbon Fiber Aerospace and Automotive Markets

- Elium – A New Technology to Make Recyclable Structural Parts

- Automated Production of Curvilinear Patch-Based 3D Preforms for High Volume Applications

- Production Advantages of Automated Fiber Placement Using Towpreg

- Global Expansion in Carbon Fiber Manufacturing: Strategic Considerations for Energy Utilization

- Commercializing Plasma Oxidation: 75% Unit Energy Savings with 3X Greater -Thoughput and Better Properties

- Carbon Fibers from Sustainable Biomass for Energy Applications

- IACMI Plenary Presentations and Panel Discussion

December 10:

- Keynote: 777x Composite Wing: New Consumer of Composite Fiber Technology

- Carbon Fiber Composites for Next Generation Military Aircraft

- The Digital Journey Continues – People & Process

- Recycle and Reuse in Composite Production - A Full Life-cycle Approach

- Composite Additive Manufacturing

- The Influence of Carbon Fiber Age on Composite Performance

- NanoStitch-enhanced prepreg for interlaminar reinforcement in fiber reinforced polymer composites

- Reinventing a Parts Manufacturer for a Changing Marketplace

- Countervail Vibration Canceling Technology

- Surface Treatment for Improving Performance and Automation in CFRP Bonding and Manufacturing

- Intelligent Automation for Composites Part Manufacturing: Internet-of-Things (IoT) with RFID sensors

Note the day two keynote, which I have underlined. This presentation, by Perry Moore, director, 777X Wing Operations, at the Boeing Co., will be the first public discussion by Boeing about the carbon fiber composite wings being developed for the 777X. Unlike it does with the 787, Boeing is fabricating the 777X wings in-house in a purpose-built plant being erected in Everett, WA. The wings represent some of the largest carbon fiber composite structures ever fabricated.

777X. Rendering.

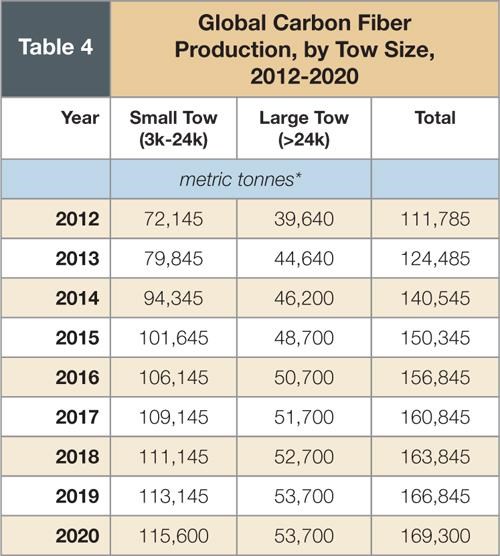

Finally, for the first time since 2012 Chris Red, in his pre-conference seminar on Dec. 8, will update his carbon fiber supply and demand data, which is highly coveted and always offers a variety of signals about where and how carbon fiber use is evolving and maturing. This table, but 2012, offers a glimpse of the kind of data that you can expect this year:

2012 carbon fiber supply data from Chris Red, prinicpal of

Composites Forecasts & Consulting LLC.

We look forward to seeing you in a few weeks at Carbon Fiber 2015. Visit www.carbonfiberevent.com for more information, and to register.

Related Content

CAMX 2022 exhibit preview: Conductive Composites

Conductive Composites expands its portfolio of multifunctional electrically conductive composite materials with a new line of NiShield nonwovens and NiBond electrically conductive two-part structural epoxy adhesive.

Read MoreComposite resins price change report

CW’s running summary of resin price change announcements from major material suppliers that serve the composites manufacturing industry.

Read MorePark Aerospace launches aerospace, MRO structural film adhesive

Aeroadhere FAE-350-1 is a curing epoxy formulation designed for composite, metal, honeycomb and hybrid applications.

Read MoreMaterials & Processes: Tooling for composites

Composite parts are formed in molds, also known as tools. Tools can be made from virtually any material. The material type, shape and complexity depend upon the part and length of production run. Here's a short summary of the issues involved in electing and making tools.

Read MoreRead Next

From the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read MoreComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read More