Pultrusion picks up speed in automotive applications

Pultrusion is one of the most cost-effective processes for manufacturing high-volume composite parts.

Pultrusion is one of the most cost-effective processes for manufacturing high-volume composite parts. Most commonly associated with glass fiber-reinforced profiles used in construction and corrosion-resistance applications, tailored pultrusions for automotive applications — including bumper beams, roof beams, front-end support systems, door intrusion beams, chassis rails and transmission tunnels — were highlighted as a key area for growth by the European Pultrusion Technology Association (EPTA, Frankfurt, Germany) in its 2018 World Pultrusion Conference report.

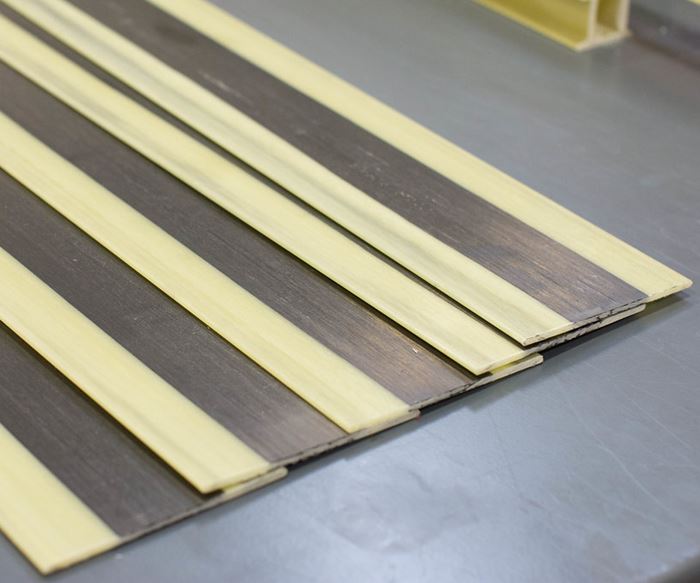

Two commercial launches highlighted at CAMX 2018 (Oct. 16-18, Dallas, TX, US) seem to confirm this technology/market fit. L&L Products, Inc. launched its Continuous Composite Systems (CCS) pultrusions, which use polyurethane resin for automotive applications such as side sills and crash structures. Designed to replace traditional metal structures that require bulkheads for necessary stiffness, CCS pultrusions offer light weight — 75% less mass than steel and 30% less than aluminum — at an economic price. Continuous fiber profiles include three variations: CCS Set using glass fiber, CCS Hybrid using a customized mix of glass fiber and carbon fiber, and CCS Extreme using only carbon fiber. A short-fiber version co-extruded with adhesive comprises a fourth product, CCS Co-Ex. The three continuous-fiber products may also be combined with L&L’s adhesives as part of the company’s in-line processing, further reducing manufacturing costs and time-to-delivery. Beyond automotive, CCS products are also aimed at wind turbine blade spar caps and industrial and architectural applications.

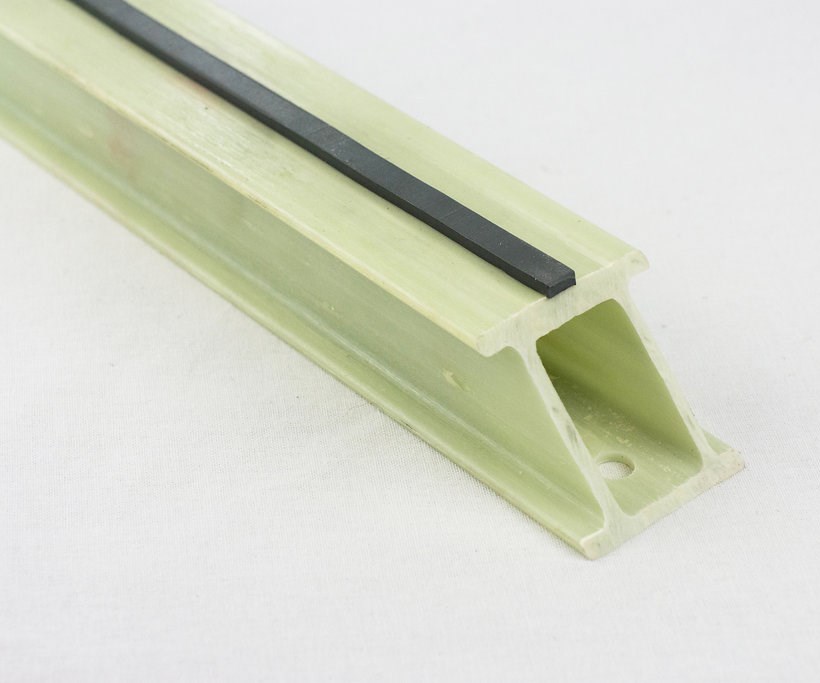

Shape Corp. (Grand Haven, MI, US) also is developing pultrusions for automotive, but with a curve — literally. The company has the first operational installation of Thomas Technik & Innovation’s (TTI, Bremervoerde, Germany) Radius-Pultrusion system, which was exhibited at CAMX 2018. Shape Corp. is a global Tier 1 supplier of metal, plastic and composite automotive components, and as described in the June 2017 CW article, “Curved pultrusion?,” its Radius-Pultrusion system was purchased “to enable manufacture of automotive bumper beams.” The company was a 2017 CAMX ACE award finalist in the Infinite Possibility for Market Growth category for its use of curved pultrusion to create highly engineered hollow and closed profiles. The technology also enables the use of multiple types of reinforcement in a single, tailored laminate. After extensive trials to develop a laminate architecture and resin formulation that best works with Radius-Pultrusion, Shape chose polyurethane. “It offers exceptional toughness properties at reasonable cost while allowing us to achieve some very fast production rates,” says Toby Jacobson, Shape’s plastic materials and process manager/advanced product development. “For reinforcements, we are running unidirectional, biaxial and triaxial noncrimp [stitched nonwoven] fabrics. We’re also pulling some individual unidirectional tows when necessary. While most of the current interest is with carbon fiber, this process will excel with fiberglass and a variety of other reinforcements.” Polyurethane and hybrid fiber pultrusions are also being developed in Europe, where TTI is working with partners such as KraussMaffei (Munich, Germany) and Covestro (Leverkeusen, Germany).

Related Content

-

Composite resins price change report

CW’s running summary of resin price change announcements from major material suppliers that serve the composites manufacturing industry.

-

XlynX Materials BondLynx and PlastiLynx for low surface energy PP, PE substrates

Award-winning Xlynx materials use breakthrough “diazirine” technology to boost bond strength up to 950% as adhesives, primers and textile strengtheners.

-

Epoxy-based structural film adhesive intended for aerospace, MRO

CAMX 2023: Park Aerospace is presenting its new aerospace-grade film adhesive material Aeroadhere FAE-350-1, in addition to other product offerings intended for aerospace, defense and spacecraft.

.jpg;maxWidth=300;quality=90)