Porous carbon fiber: Permeable, adsorptive and conductive

New Toray development holds promise for advanced batteries, gas-separation technologies for fuel cells.

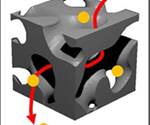

Toray’s new porous carbon fiber (top left, showing hollow central shaft) features a controllable, nano- or micro-scale pore structure throughout the entire fiber (top right). That porous structure helps make the material an effective filtration medium that may be useful as the support structure of gas-separation membranes. Because carbon also has well-known adsorption properties (for chemical as well as physical filtration), and is an effective thermal and electrical conductor, the porous carbon fiber may also find use in advanced battery systems and catalyst carriers used in chemical processing. Source | Toray Industries Inc.

In mid-November 2019, Toray Industries Inc. (Tokyo, Japan) announced it had developed the world’s first porous carbon fiber with a continuous, nano- and/or micro-scale pore structure, which it hopes to commercialize within the next five years. Specifically, one potential application for the product is use in gas separation technology, employed by a variety of industries to separate carbon dioxide (CO2), biogas, hydrogen and other gases.

Toray reports that conventional approaches for gas separation occur at large facilities that, themselves, use a lot of energy and produce significant CO2 emissions. A newer, more environmentally sustainable approach to gas separation employs nanoporous membranes for gas filtration that use significantly less energy. However, despite showing promise, Toray says that to date this method has lacked the efficiency and durability needed for large-scale, long-term use.

According to the company, Toray’s new porous carbon fiber product could help solve this problem — with potential for use in hydrogen production for fuel cells — by enhancing the performance of current gas-separation membranes, making membranes thinner, lighter, more compact and better able to withstand heat, pressure and chemicals.

Porous filtration media

Nano- and microporous filtration media are not new. A handful of polymers — most of them thermoplastic — are used to produce both nanoporous flat membranes as well as nanoporous fibers. Typical applications include high-performance water filters (for industrial and potable water); beverage and food filtration (to improve color, odor, or taste); medical filters (for blood separation (apheresis) and blood filtration (dialysis)); as well as industrial gas separation (for a wide range of industries and processes, including chemicals and petrochemicals, power, mining, steelmaking, medical, fertilizer production, environmental protection, electronics and aerospace).

The most common polymers used for high-performance filtration applications include polyethersulfone (PES), polysulfone (PSU), polyvinylidene fluoride (PVDF), polytetrafluoroethylene (PTFE) and cellulose acetate (CA). For the most demanding filtration conditions — such as high or low temperatures, aggressive chemicals, or applications with high levels of solids — ceramics (such as aluminum oxide) and metals (such as titanium dioxide and stainless steel) also are used.

Depending on the needs of the application, filtration media can be produced in several distinct porosity levels with pore sizes on the order of 0.1 micrometer for microfiltration, 0.01 micrometer for ultrafiltration, 0.001 micrometer for nanofiltration and 0.0001 micrometer for reverse osmosis.

For high-performance filtration media, critical technical requirements include: good and broad chemical resistance, not only to the materials being separated but also to sodium hypochlorite, a common disinfecting agent used to clean membranes; good mechanical strength, since many filters apply high pressures to force the separation of solids, liquids and gases; permeability, to provide the filtration function; and low fouling, so membranes can be kept clean for efficient, functional, long-term operation.

Porous carbon fiber

That carbon fiber can be used as a nanoporous filtration medium is attractive in a number of ways. First, activated carbon — a form of carbon with a small volume of tiny holes used to increase available surface area for adsorption and/or chemical reactions — has long been used as one component in a range of lower-performing filtration systems. With atomic carbon’s ample supply of empty orbitals, and activated carbon’s increased surface area, the material can be an effective medium to trap and bind (adsorb) a variety of active substances. Unfortunately, since activated carbon is essentially solid, its permeation function is mostly confined to the surface of the substrate, and its filtration function is primarily physical (not chemical), which limits the types and sizes of substances that can effectively be separated.

In the case of Toray’s porous carbon fiber — or powders produced from grinding such fiber — the pores are continuous throughout the structure, meaning that products made from the material should be able to both physically as well as chemically filter. By leveraging atomic carbon’s adsorption properties, the nanoporous carbon fiber may prove to be useful for electrode materials and catalyst carriers in high-performance batteries. What’s more, carbon in all of its solid forms is both a good thermal conductor as well as a good electrical conductor — features that could prove useful in certain applications.

Toray reports that both pore size (micro- through nano- levels) and cross-sectional pore shape are controllable in its product regardless of whether they create a “solid” porous fiber or a hollow porous fiber (with a central shaft along the length of the fiber). So far, Toray has been able to create “large” as well as “small” pores (although no specifics on actual pore sizes was provided). Since carbon fiber already has been carbonized and graphitized, it is chemically stable and very stiff and strong — properties that also can be harnessed in the production of stronger, more compact gas-separation membranes.

Reportedly, the company drew on three internal areas of expertise to develop the new product: polymers, carbon fiber, and separation membrane/water filtration technologies.

On Dec. 11, 2019, Toray held a ribbon cutting ceremony to open its new R&D Innovation Center for the Future. The two-building facility, on the premises of the company’s Shiga Plant in Otsu, Japan, where the company began operations in 1926, will serve as global headquarters for a number of strategic initiatives, including porous carbon fiber, by engaging academic institutions and industry partners from diverse fields. Toray reports the company already is collaborating with several partners to better leverage each organization’s expertise to drive the commercialization of advanced gas-separation membranes to support economical and eco-friendly methods for natural gas and biogas purification and hydrogen production for fuel cells that power electric vehicles and buildings. That team says it has developed a concept for a new type of gas-separation membrane that will be more resistant to heat, chemicals and pressures. Combining Toray’s porous carbon fiber as the support layer and partner technology for the gas-separation layers, the proposed four-layer system should be capable of separating out and purifying natural gas (layer A), biogas (layer B), hydrogen (layer C) and propylene (layer D).

The company also reports that it is continuing research into this new material to foster carbon recycling, tap hydrogen energy production and shrink industry’s environmental footprint. It is one arm of Toray’s Group Sustainability Vision to help materialize low-carbon economies by 2050 through contributions to environmental, resource management and energy issues.

Related Content

Opportunities and challenges for composites in electric vehicles

Polymer and material specialists at chemical consulting firm ChemBizR reflect on the role of composites in current and future efforts to make electric vehicles more efficient — and more attractive for consumers.

Read MoreAZL opens new project in cell-to-pack composite battery enclosures

AZL specialists are to kick off new project consortium Oct. 27, 2022 geared toward developing new battery enclosure concepts for cell-to-pack technology. Interested companies can still apply for participation.

Read MoreUniFORM: High-quality, high-complex EV battery enclosures at low cycle times, low tooling costs

Stellantis subsidiary CpK Interior Products Inc. recently completed a design challenge to prove out its vacuum-assisted wet compression molding process for CFRP battery trays.

Read MoreMass, cost, durability improvements: EV battery enclosures, Part 2

As interest grows in composite battery covers and trays, composite materials suppliers work to meet current and future needs of automakers, battery module producers.

Read MoreRead Next

Toray creates world’s first porous carbon fiber with nano-sized continuous pore structure

Applications include lighter structures for batteries, H2 production and CO2 recycling.

Read MorePorous carbon fiber shows potential for automotive energy storage applications

Researchers at Virginia Tech explore industrial uses for porous carbon fiber in electrochemical energy storage.

Read MorePorous carbon fiber made from block copolymers may enable energy storage

Researchers at Virginia Tech have developed a process to synthesize porous carbon fibers with uniform size and spacing.

Read More