Mars habitat concepts feature 3D-printed composites

NASA has announced the design competition finalists for its 3D-Printed Habitat Challenge.

NASA has declared Mars the next tangible frontier for expanding human presence and the space agency has released a report detailing how it will reach the red planet in the 2030s. Since it will take plenty of ingenuity and originality to allow astronauts to live on Mars, NASA and the National Additive Manufacturing Innovation Institute, known as America Makes, held a $2.25 million competition to design and build a 3D-printed habitat for deep space exploration. The design competition challenged participants to develop architectural concepts that take advantage of the unique capabilities 3D printing offers to imagine what habitats on Mars might look like using this technology and in-situ resources.

NASA recently announced the winners of the design competition. Teams were judged on many factors, including architectural concept, design approach, habitability, innovation, functionality, Mars site selection and 3D print constructability. I read up on the finalists and found composites was involved in several of the designs.

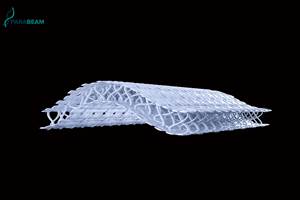

The runner-up was the team Hybrid Composites, which is a multidisciplinary group of experts who are conducting research in architecture, digital fabrication, computation, material science, additive manufacturing, robotics, mechanical engineering and aerospace engineering. The team’s approach was to pursue the use of composite materials and robotic fabrication techniques to challenge and go beyond the current cement based 3D printing approaches. The group’s proposal is a combination of a 3D-printed composite lattice that is extruded through robotic arms, serving as structure, and inner layers of robotically formed composite shells as high performance enclosures.

Here’s their explanation:

"Rather than using extrusion of powder based cement based materials, our team proposes a hybrid approach that integrates multiple robotically controlled fabrication techniques that employ the use of high performance composite fibers and fast curing polymers that react to heat or UV light. Primary structural systems and shell enclosures can be 3D-printed by extruding composite fibers woven into various profiles such as strands, sleeves and fabrics through robotically controlled mandrel systems. Primary material for strand production can ideally and abundantly be made by using the local basalt, which can be sourced and produced at sites that have a history of volcanic activity in any terrestrial or extraterrestrial context. If special technological requirements need to be met, conductive metal fibers, fiber optics and other fibers that transmit electricity, data and light can be woven into the composites at designed locations."

The Mars Terrain Intelligence Collaborative put together a design called Marsapia. The group said that the most ubiquitous and accessible material on Mars is the high (6-14%) iron content silica sand, which covers the vast majority of the planet’s surface. Once the iron and silica have been separated from the soil matrix, using thermal and magnetic processes, these materials will be moved to hoppers and become the media for induction extrusion/plasma arc sintering heads, positioned by multi-axis CNC hydraulic/servo-driven arms. The robot controlled print-heads could produce the first permanent structures on Mars.

According to the group: "The monolithic composite shell will be composed of a sintered ferrous latticework on the internal and external surfaces of the structure and a vitrified then devitrified silica core, effectively granite. The lattice and core will provide tensile and comprehensive properties approximating yet surpassing the structural efficiency of ferro-cement or reinforced concrete due to an algorithmiclly regulated deposition of material possible only by through 3D printing. This variable rate of deposition will allow the section modulus of the sintered medium to respond to the specific structural requirements of the form. The resulting steel and silica forms will serve as bunkers, protecting the Martian inhabitants against solar radiation, small bolide impact, strong prevailing winds, and related sand storms. They will also provide structural reinforcement, insulation, and protection for a nested system of prefabricated graphite/resin inflatable containment units which will provide beta radiation protection, and contain the inhabitable atmosphere."

The Red House team, a collaboration among a group of graduate and undergraduate students studying industrial design, graphic design, architecture and physics, undertook an iterative design process to arrive at its approach to Martian habitation. With a focus on near future feasibility, the group’s design adapts an existing industrial process, basalt composite rod manufacturing, to 3D print a structural frame which serves as the core of their proposed habitat.

"First, the required basalt will be collected directly from the Martian surface. Next, the structural frame will be printed in place as a series of spiraling and interlacing ribs from one continuous rod, requiring no assembly. Once the frame is in place, the crew lander will be integrated as the habitat’s airlock. The resulting assembly will be covered with spent parachutes used during landing. This nylon fabric, pulled tight over the ribs of the frame, will support the raw regolith which will be piled on top of the habitat. The parachutes will also act as backing for a series of other layers used for environmental protection. In this way, only the frame must be made from highly processed in situ material and very little material is required from Earth. This system is optimized for quick, lightweight and practical construction," the group stated.

Video: This lunar habitat is made of glass-fiber-filled ABS and offers three important lessons for printing large parts. Watch here.

Related Content

Highly tunable, woven lattice reinforcements target automotive structures

CAMX 2023: Startup Weav3D will be demonstrating its two collaborative automotive demonstrator parts and present two conference papers.

Read MoreMaterials & Processes: Fibers for composites

The structural properties of composite materials are derived primarily from the fiber reinforcement. Fiber types, their manufacture, their uses and the end-market applications in which they find most use are described.

Read MoreCAMX 2022 exhibit preview: Parabeam

Parabeam’s 3D E-glass woven fabrics, particularly ParaGlass and ParaTank, continue to advance composite sandwich structures with high flexibility, strength and application versatility.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreRead Next

Composites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read More