Looking Forward

Current composite tether designs are leveraged to take advantage of existing oil-field manufacturing facilities. The wirerope stranding facilities, umbilical closing machines, steel anchors and installation methods used today for steel and synthetic cables can immediately accommodate rope-style composite tethe

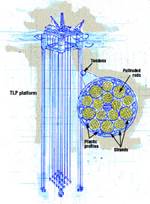

Current composite tether designs are leveraged to take advantage of existing oil-field manufacturing facilities. The wirerope stranding facilities, umbilical closing machines, steel anchors and installation methods used today for steel and synthetic cables can immediately accommodate rope-style composite tethers. However, future designs could be more flexible. Rods could be pultruded in any shape. Salama of Conoco adds, “We are looking at materials with a specific gravity lower than water to reduce the pretension.” For example, PVC profiles with a specific gravity of 1.4 could be replaced with polyethylene profiles that have a 0.9 specific gravity (10 percent lighter than water). Other lightweight options include polypropylene, polystyrene and acrylonitrile butadiene styrene (ABS). Alternatively, a tether could be manufactured from a single strand, which would greatly simplify the entire system. The Doris Engineering/Freyssinet partnership envisions an extension of composite cable technology to moorings for other floating deepwater structures, such as catenary cables for spars, semi-submersibles and production ships.

Related Content

-

Composite rebar for future infrastructure

GFRP eliminates risk of corrosion and increases durability fourfold for reinforced concrete that meets future demands as traffic, urbanization and extreme weather increase.

-

Recycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.