ITHEC: Thermoplastics, hybrids for auto, industrial, aero

The International Conference & Exhibition on Thermoplastic Composites features Vokswagen’s new Open Hybrid LabFactory, Airbus’ work on short-fiber aircraft structures, low-viscosity thermoplastic RTM and more.

Compression molded thermoplastic composite clips like this one are seeing increased use in aerospace and other end markets. Thermoplastics are proving uncommonly attractive throughout the compoosites industry.

ITHEC 2014 (Oct. 27-28, Bremen, Germany) is a unique expert conference focusing on structural thermoplastic lightweight constructions in aerostructures, automotive and energy applications as well as hybrid materials and technologies. Over 350 international participants are expected, including leaders in the newest technology developments.

The accompanying International Exhibition on Thermoplastic Composites will present new lightweight concepts, materials trends and innovative manufacturing technologies.

Professor Dr.-Ing. Lothar Kroll, member of the ITHEC steering committee and head of the Institute for Lightweight Structural Construction at the Chemnitz Technical University (Chemnitz, Germany) sees innovations in lightweight construction increasingly based on the synergetic combination of a wide variety of materials. In order to address the current issue of separate material handling processing, multiple process steps and expensive joining technologies, the MERGE Excellence Cluster is developing efficient-resource mass-production manufacturing of high-performance, multi-functional structures. Kroll describes, “active components such as sensors, actuators and generators are integrated as electronic modules with in-line and in-situ processes to attain next-stage highly functional lightweight structures." This topic will be presented on Day Two of the conference.

On Day One, Johnson Controls (Burscheid, Germany) will discuss its work in the CAMISMA project to design and manufacture a hybrid carbon fiber/polyamide/metal seat back structure using recycled fibers, novel in situ polymerized unidirectional and nonwoven preforms, glass-reinforced direct long fiber injection material and steel inserts, which are integrated and attached via a one-shot combined thermoforming and injection molding process to cut weight over 40 percent vs. metal with comparable cost, cycle time and safety performance.

Other highlights include:

“Automobile CFRP Production and Potentials for Thermoplastic Composites” keynote from BMW (Landshut, Germany)

“Smart Production of Hybrid Material Automotive Structures at the Wolfsburg Open Hybrid LabFactory”

“New Concepts for Structure Parts Based on Short Fiber-reinforced Injection Molding” by Airbus (Hamburg and Bremen, Germany)

“Development of RTM TP with Low Viscosity Thermoplastics” by CETIM (Nantes, France)

“Recent Japanese Activity in CFRTP for Mass Production Automobiles”

“Electro Bonded Laminates for High Performance 3D Morphing Structures” by ETH Zurich (Switzerland)

“How to Qualify an Offshore Thermoplastic Composite Pipe System” by Airborne Oil & Gas B.V (Ijmuiden, NL)

“Latest Developments in Thermoplastic Composites for Automotive Applications” by FAURECIA (Paris, France)

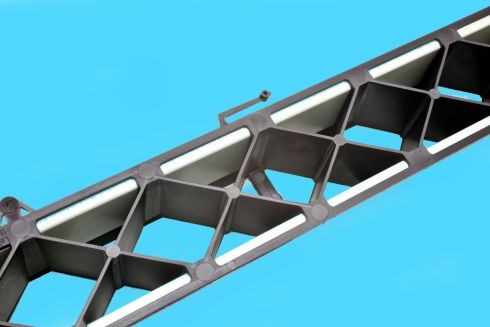

The Erlangen carrier developed by the Institute of Polymer Technology (Lehrstuhl für Kunststofftechnik or LKT, Erlangen, Germany) illustrates the latest in-line processes for joining metals to plastics and fiber-reinforced composites, offering reduced cost and time via In-Mold-Assembly (IMA) compared to Post-Mold-Assembly (PMA).

SOURCE: LTK

This technology is advancing rapidly, with companies like injection molding machine manufacturer KraussMaffei (Munich, Germany) seeing not only a burgeoning market for hybrid solutions, but also increasing opportunity to replace traditional materials with reinforced thermoplastics which offer more complex geometry, faster cycle times and integration not just of different materials but also of production steps like joining and finishing, where color can be integrated into the molding operation vs. post-mold painting.

The breadth and depth of thermoplastic composites information being offered at ITHEC make this an event well worth attending!

Related Content

MFFD thermoplastic floor beams — OOA consolidation for next-gen TPC aerostructures

GKN Fokker and Mikrosam develop AFP for the Multifunctional Fuselage Demonstrator’s floor beams and OOA consolidation of 6-meter spars for TPC rudders, elevators and tails.

Read MoreComposite resins price change report

CW’s running summary of resin price change announcements from major material suppliers that serve the composites manufacturing industry.

Read MoreMaterials & Processes: Tooling for composites

Composite parts are formed in molds, also known as tools. Tools can be made from virtually any material. The material type, shape and complexity depend upon the part and length of production run. Here's a short summary of the issues involved in electing and making tools.

Read MoreMaterials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

Read MoreRead Next

CW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read MoreComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read More