SOURCE for all images | Cetim Grand Est

Cetim (Nantes, France) is already well-known for its QSP (Quilted Stratum Process) for industrialized production (< 1-minute cycle time) of thermoplastic composite parts, and also for its QSD (Quilted Stratum Design) software which optimizes such parts, including how to reuse production scrap back into the part. Its third enabling technology is a modular production line for turning thermoplastic scrap with and without fiber reinforcement into organosheet panels that offer desirable properties and cost.

Pilot line at Cetim Grand Est

This thermoplastic composite recycling process was developed by Cetim Grand Est (Mulhouse, France). Formed in 1977 as Cetim Cermat, it merged with CRITT Matériaux Alsace in 2018 to provide technological support for companies in the Alsace Lorraine and Champagne-Ardenne regions of France. “Cetim Grand Est is in charge of recycling technologies for polymers and thermoplastic composites,” explains Clément Callens, business unit manager at Cetim Grand Est for the Mulhouse-based Industry of the Future team, including thermoplastic process and online monitoring projects. “We have fifteen people in this division and work with universities and companies from a wide range of industries, creating interdisciplinary teams to solve challenging problems.”

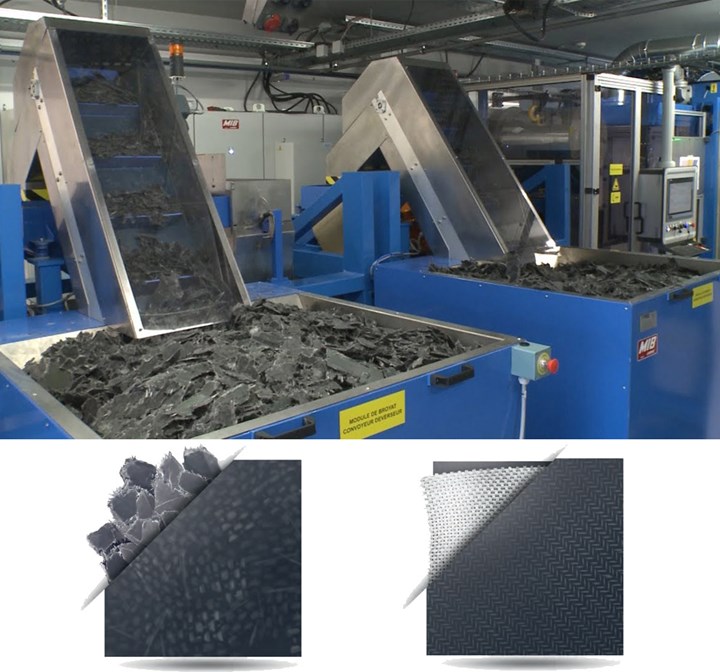

“The pilot production line we have established in Mulhouse was developed to show the world that this innovative thermomechanical process for recycling production scraps is possible,” Callens continues. “This line is similar to QSP in philosophy: an automated system that is flexible and modular, which enables companies to use the technology in an efficient and cost-effective way. We actually receive scrap from the QSP line in Nantes, or from other customers, and then upcycle it into various organosheet materials and panels, with the goal of maintaining the integrity of the composites for higher performance compared to traditional materials and traditional recycled composites.”

Thermosaïc and ThermoPRIME

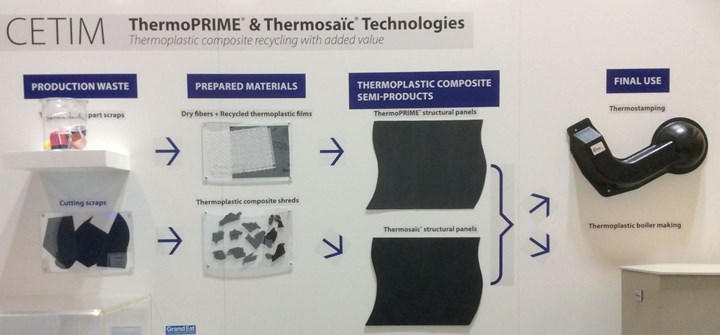

The line combines two separate approaches: Thermosaïc and ThermoPRIME.

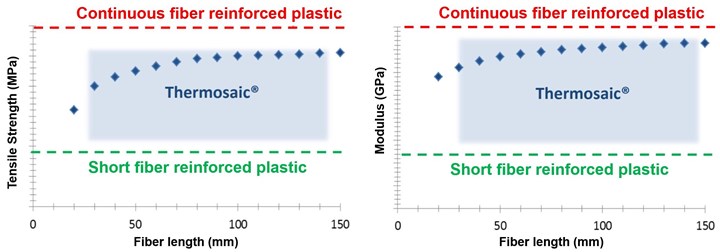

Thermosaïc takes thermoplastic composite production scrap from cutting and trimming (or from end-of-life parts), coarsely shreds it and then uses a thermomechanical process to convert the shreds into organosheet. “We call it a composite structural panel,” says Callens, “but it’s basically like organosheet.” The term organosheet evolved in Europe to describe fabric-reinforced thermoplastic prepreg, semipreg or preconsolidated blanks that could be thermoformed and overmolded into composite parts. Thermosaïc products are quasi-isotropic, and fiber length is kept as long as possible in order to maximize mechanical properties. “They are in the middle between short fiber sheet and classic organosheet,” Callens notes. “The aim of the technology is to find a good compromise between the shred size and the properties of the panel because you always have to link performance with cost. The process must be flexible and cost-effective, meaning cheaper than virgin material.”

In Cetim’s Thermosaïc process, fiber length is kept as long as possible in order to maximize mechanical properties.

“We use the same process line to make ThermoPRIME structural panels,” he explains. “It is the same basic concept, but in this approach, we begin with unreinforced thermoplastic scrap or end-of-life parts that have been recycled into film. Films made of different materials already are available in the market. We then add virgin, natural, recycled or any other dry continuous fiber to produce an organosheet that has the same properties as virgin material but at a lower cost. The fiber impregnation uses a continuous process which is cheaper versus the batch processing of classic organosheet.”

Cetim’s production line for Thermosaïc and ThermoPRIME is modular, allowing flexibility to accommodate different types of scrap/recycled input and desired finished products.

Demonstrations, cost savings and supply chain

Demonstrations to date have shown more cost savings with higher performance thermoplastics like PEEK (polyetheretherketone) or PPS (polyphenylene sulfide) versus materials like PP (polypropylene), which are already low-cost as virgin materials. In addition to these polymers, Callens’ team has processed PA6 (polyamide6) and developed different kind of glass fiber-reinforced polymer recycled products, working with companies, for example Porcher (Eclose-Badinières, France), to produce Thermosaïc and ThermoPRIME panels. The team is also working on recycled carbon fiber reinforced polymer panels.

How do you see the recycling supply chain developing? “We are working now to transfer this technology to industry, collaborating with Tier 1 suppliers and materials manufacturers,” says Callens. “Cetim Grand Est is working with industry to complete proof of concept and feasibility studies. It is also working, in collaboration with the machine manufacturer partner, to adjust the line to meet the specific needs of customers and work with customers to help define the optimal production modules and parameters.”

Thermosaïc and ThermoPRIME were recognized at JEC World 2018 with the Innovation Award for Sustainable Development. Clément Callens is scheduled to present further details on this technology May 12 at JEC World 2020 (Paris, France).

Related Content

Composite molding compound replaces Invar for lightweight small satellite structures

Patz Materials and Technologies and Lawrence Livermore National Laboratory developed a new monolithic optics housing with 80% less weight, near-zero CTE and the high-volume manufacturing required for commercial space.

Read MoreMaterials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

Read MorePlant tour: National Institute for Aviation Research, Wichita, Kan., U.S.

NIAR, located at Wichita State University in the heart of the American aerospace manufacturing industry, has evolved to become a premier hub of teaching, R&D, creativity and innovation.

Read MoreClemson Composites Center: Working with industry to transform composites

Offering liquid and thermoplastic composites molding, LCA-weighted simulation, full testing to validate materials/process data cards, CCC’s digital life cycle approach unites manufacturing, microstructure, part property map and structural analysis.

Read MoreRead Next

Composites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read More

.jpg;maxWidth=300;quality=90)