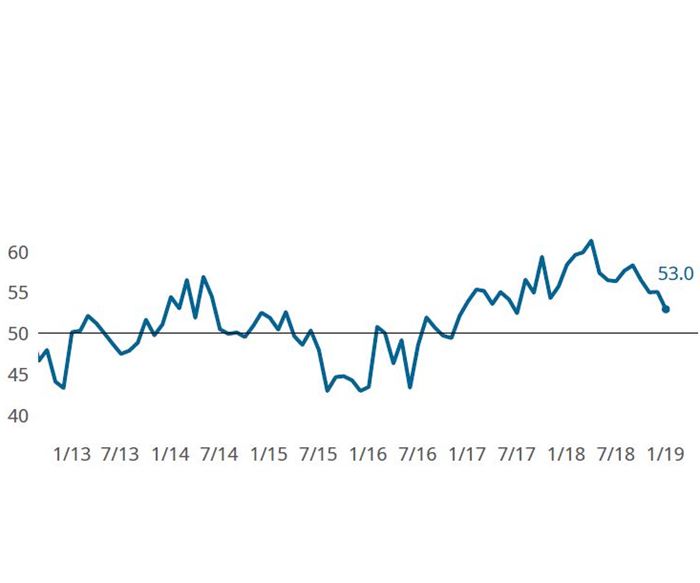

Index sees gradual start to 2019 on slow new orders growth

The Composites Business Index moved lower in the first month of 2019, with slowed growth in new orders.

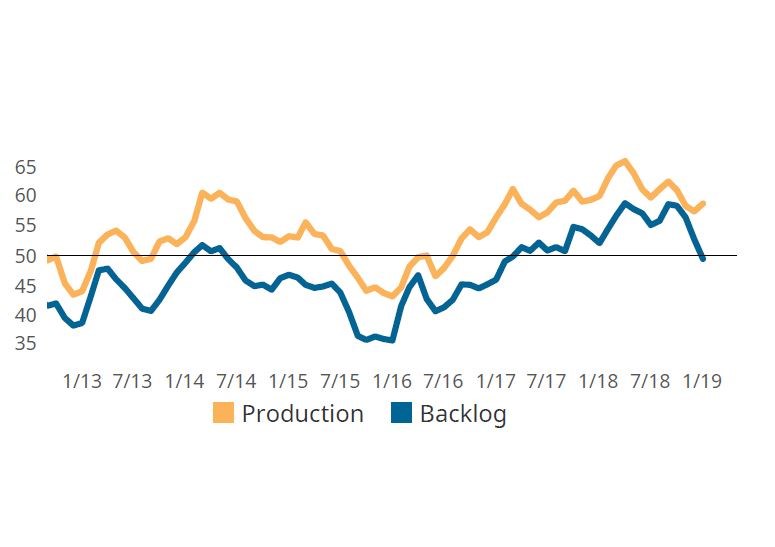

The January GBI: Composites Index moved lower from the prior month to 53.0. The latest reading continues a slowing growth trend in the Index first established in the second quarter of 2018. The latest reading is 9.7 percent lower compared to the same month one-year ago — near the time that the Index was headed to a new all-time high in early 2018. Gardner Intelligence’s review of the underlying data indicates that the Index was propelled higher during the month by production and supplier deliveries. The Index, calculated as an average, was pulled lower by new orders, employment, exports and backlogs. Backlogs was the only component to contract in January; the last time backlogs contracted was December 2017.

January marks only the second time in nearly a year that the reading for supplier deliveries was not the leading component of the Index. The supplier deliveries component has regularly been the fastest growing component of the Index since early 2018 when new orders and production readings peaked at all-time record highs. This trend suggests that the composites supply chain diligently expanded throughout 2018 in order to keep up with heightened composite orders.

According to the latest data, production expanded quickly at the start of the year while new orders growth simultaneously slowed. The combined effects of these conditions resulted in the sharpest contractionary reading in backlogs in over two years. Exports, which have experienced several recent months of contraction, did not mitigate the lower backlog reading.

More information about the Composites Fabricating Index can be found at http://www.gardnerintelligence.com/

Related Content

-

Plant tour: ÉireComposites, Galway, Ireland

An in-house testing business and R&D focus has led to innovative materials use and projects in a range of markets, from civil aerospace to renewable energy to marine.

-

Recycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

-

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

.jpg;width=70;height=70;mode=crop)